Transmission shaft support unit

A technology for supporting units and transmission shafts, which is applied in the field of bearing manufacturing, can solve problems such as damage to transmission shaft support units, frequent axial impact loads, and reduced precision of rubber pads, so as to improve integrity, improve axial torsion resistance, and improve The effect of compressing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

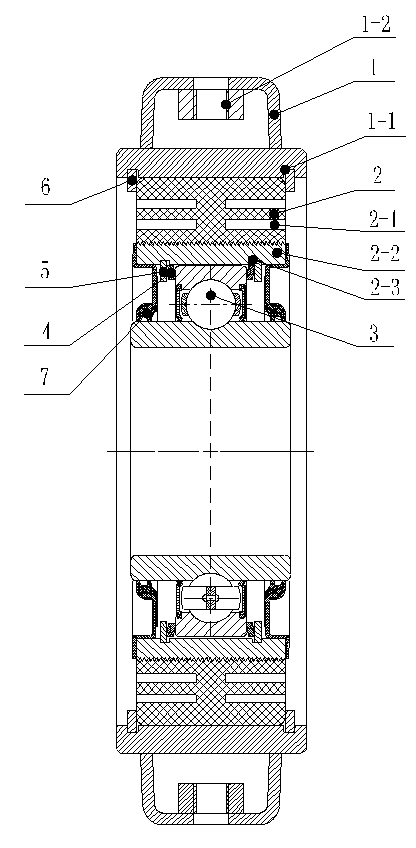

[0015] Such as figure 1 As shown, the transmission shaft support unit in the specific embodiment of the present invention includes a support base 1, a rubber shock absorber 2, a support bearing 3, two wave springs 4, two small inner circlips 5, and two large inner circlips 6 , two sealing rings 7.

[0016] Positioning holes 1-2 are provided on the support base 1 . Two retaining ring grooves 1-1 and a large internal retaining ring 6 for fixing the rubber shock absorbing pad 2 are arranged on the inner hole wall of the support seat 1 . There is installation gap between the inner hole wall of support bearing 3 outer circles and metal ring 2-2.

[0017] The rubber damping pad 2 is made of EPDM / PP TPV material, and honeycomb-shaped blind hole grooves 2-1 are provided on its two peripheral end faces. The inner hole of the rubber shock absorbing pad 2 is inlaid with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com