Dynamic pressure bearing, high-speed fluid power machinery and high-speed centrifugal compressor

A dynamic pressure bearing and bearing technology, applied in the field of dynamic pressure bearings, can solve the problems of small bearing capacity, easy deformation, unstable operation, etc., and achieve the effects of improving rigidity and stability, reducing vibration and reducing operating noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

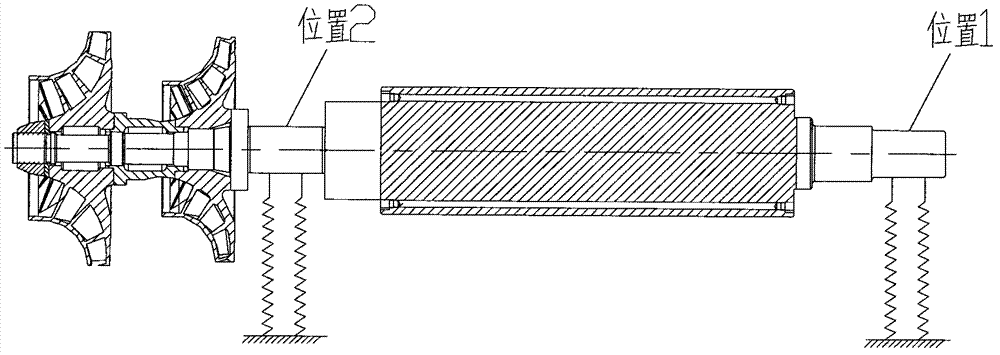

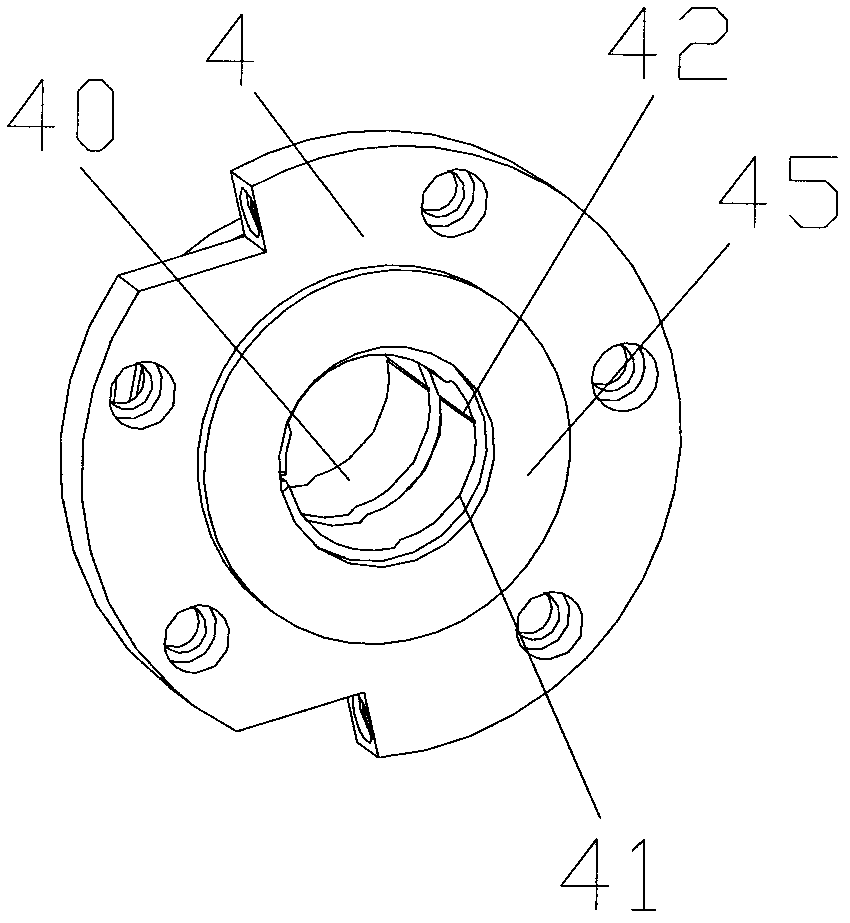

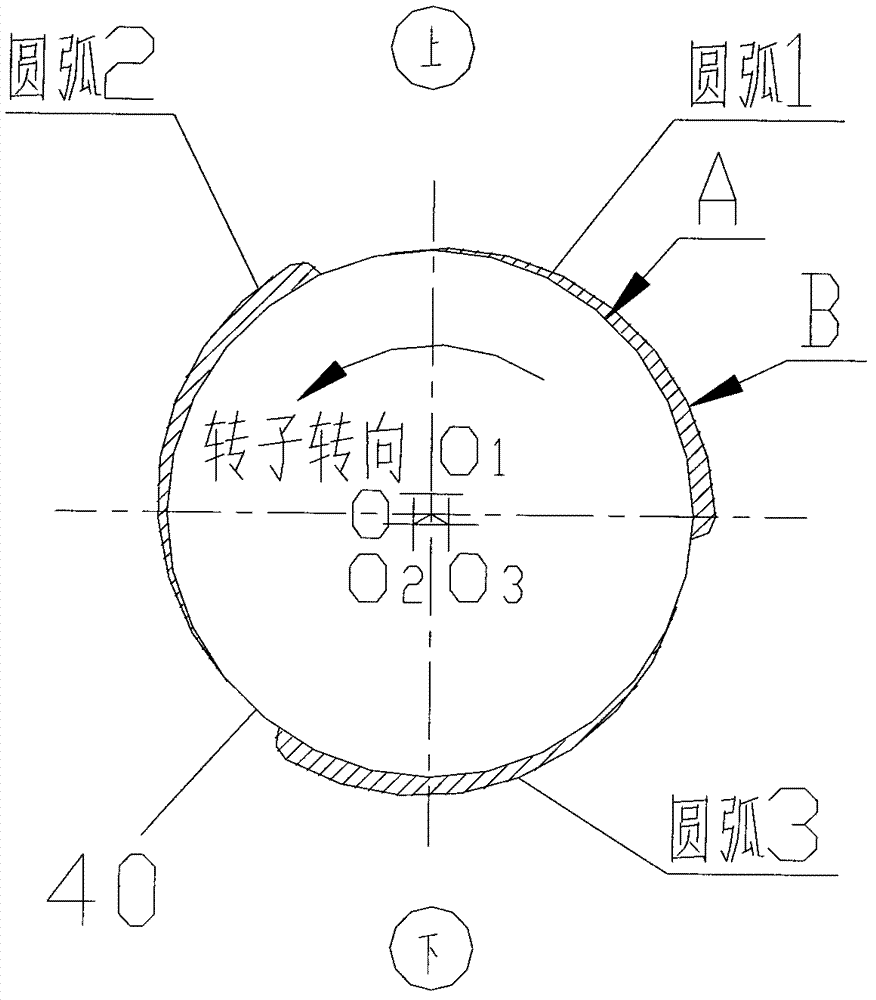

[0041] Attached below Figure 1-5 The present invention is described:

[0042]Although the dynamic pressure bearing proposed in this application can also be applied to ordinary high-speed fluid power machinery, it is especially suitable for heavy-duty high-speed fluid power machinery, because it can not only bear heavy loads, but also ensure that the rotor runs at high speed under heavy loads. It maintains relatively high efficiency and operation safety and stability, and at the same time greatly prolongs the service life of the bearing and improves economic benefits. Take the high-speed centrifugal compressor as an example below to describe the present invention in detail:

[0043] Such as figure 1 As shown, the motor rotor of this high-speed centrifugal compressor is a cantilever structure, and the impeller 2 adopts two stages, which are directly installed on the cantilever end of the motor rotor in a direct connection, and are set in the same direction; the motor is a DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com