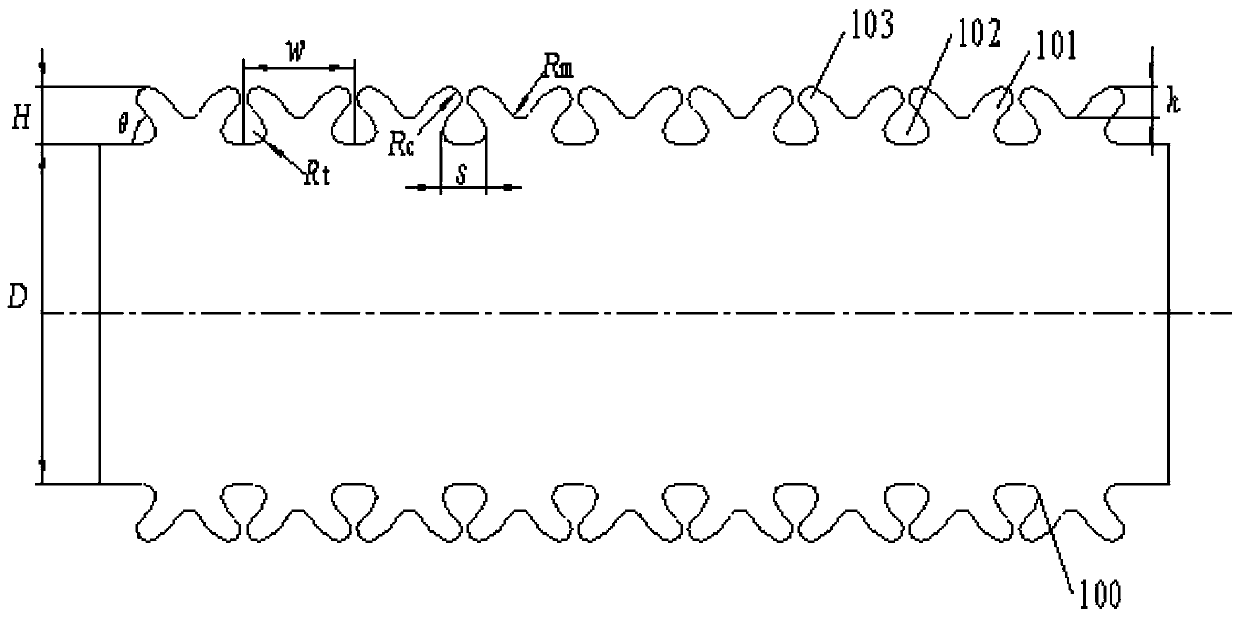

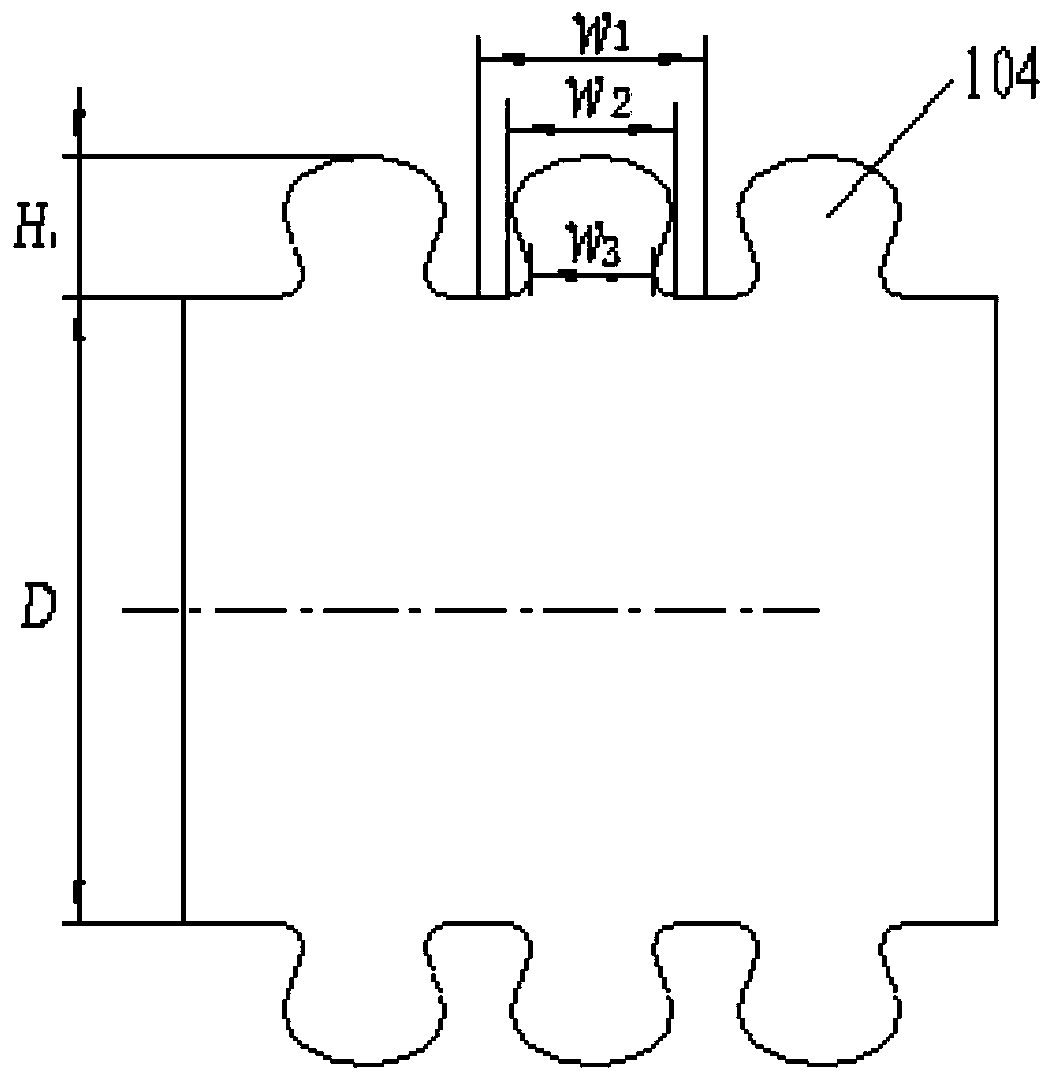

Y-shaped corrugated pipe with one-way elongation compensation, forming device and forming method

A bellows, one-way technology, applied to expansion compensation devices, pipe components, pipes/pipe joints/fittings for pipelines, etc., can solve problems such as the inability of bellows to meet the requirements, and reduce mold design and processing costs. Good axial elongation compensation ability and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

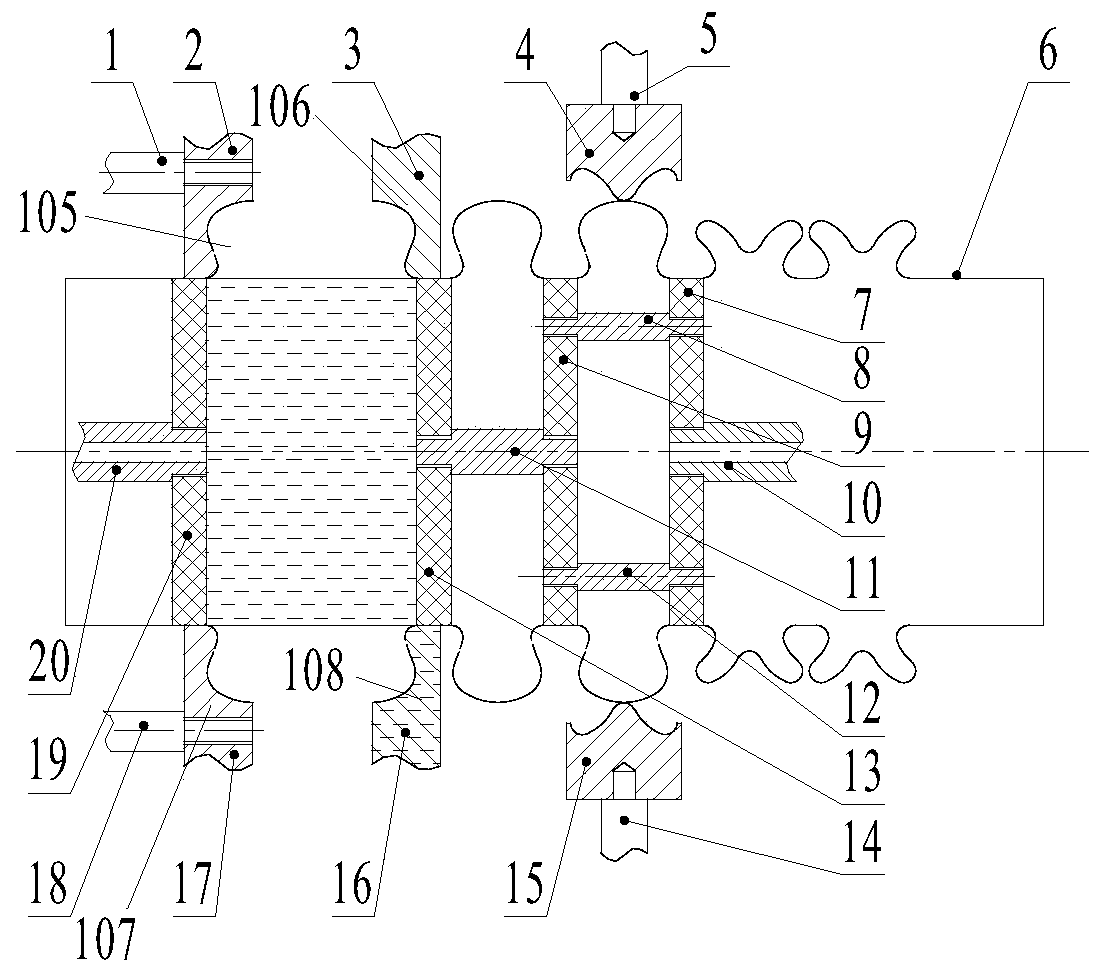

[0066] Fix the fixed ends of the upper die 2, the lower die 17, the upper positioning die 3, and the lower positioning die 16 on the upper and lower beams of the expansion wave machine respectively, and at the same time, fix the multiple split punches on the uniform through their respective push rods. On the piston rod of the cloth hydraulic cylinder, the molds are arranged in order from left to right, that is, the upper die, the lower die, the upper positioning die, the lower positioning die and multiple split punches, the upper die, the lower die and the upper die. The locating mold and the lower locating mold hold the tube blank 6 tightly from the outside under the action of the upper beam and the lower beam of the expansion machine, as image 3 shown.

[0067]Place the four sealing rings in the bellows tube blank, and the first sealing ring 19 is pushed by the first oil discharge rod to the position where its smooth surface is on the same surface as the force point of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com