Float-type drop energy-eliminating noise-reducing device

A floating, noise-reducing technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of noise pollution, secondary noise, non-acceptance, etc., and achieve stable noise-reduction effects and reduce water-falling noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

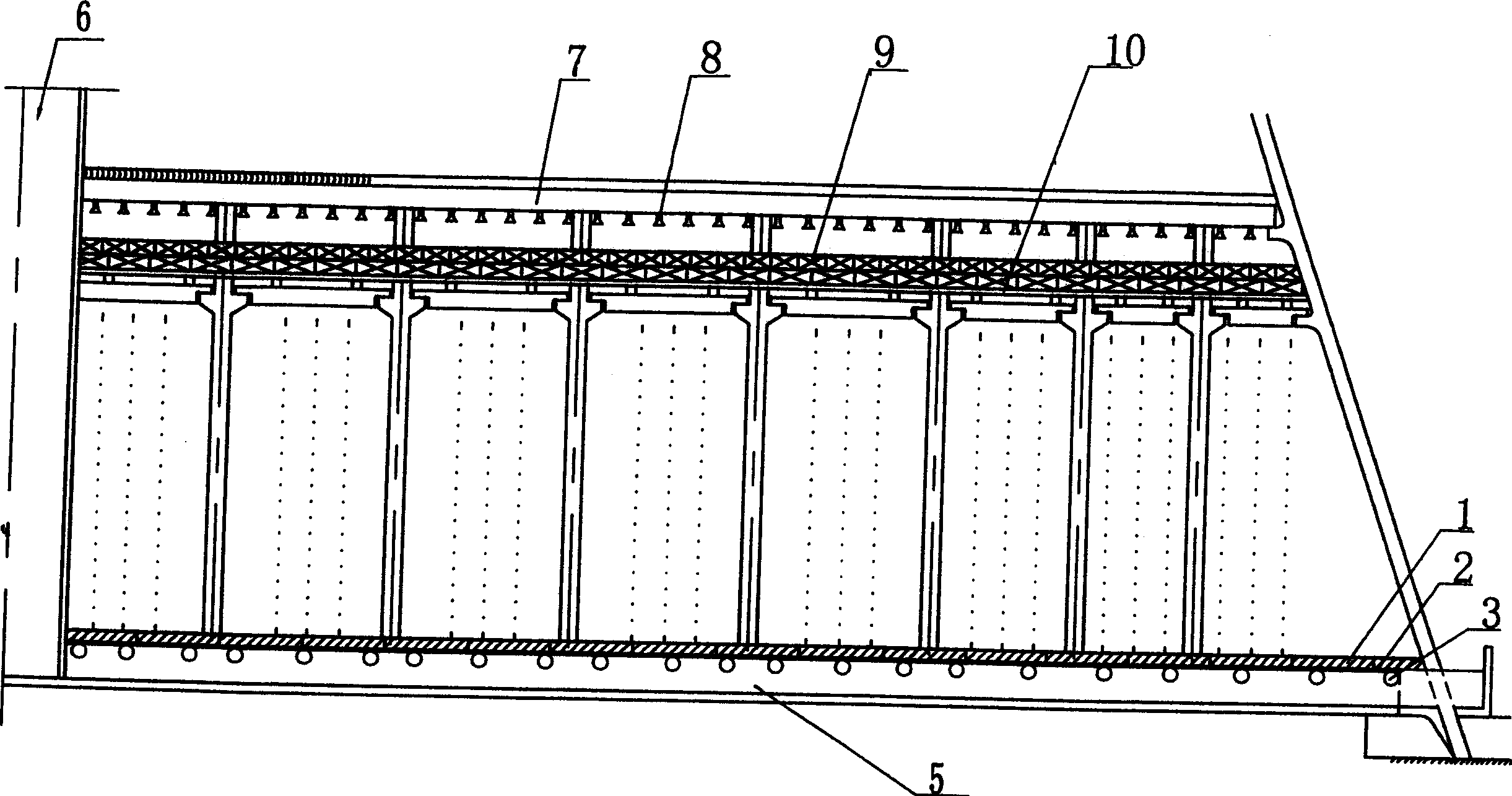

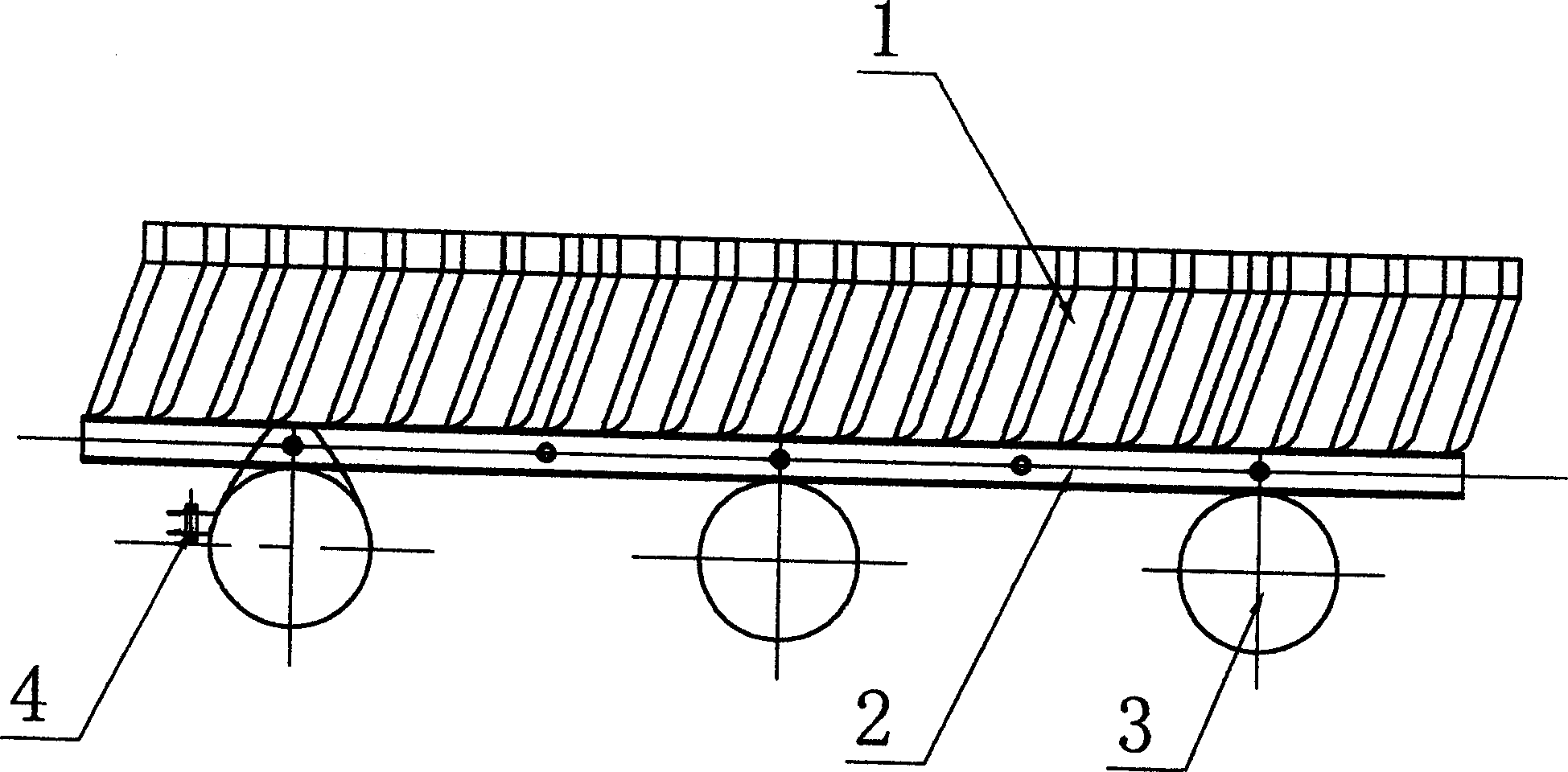

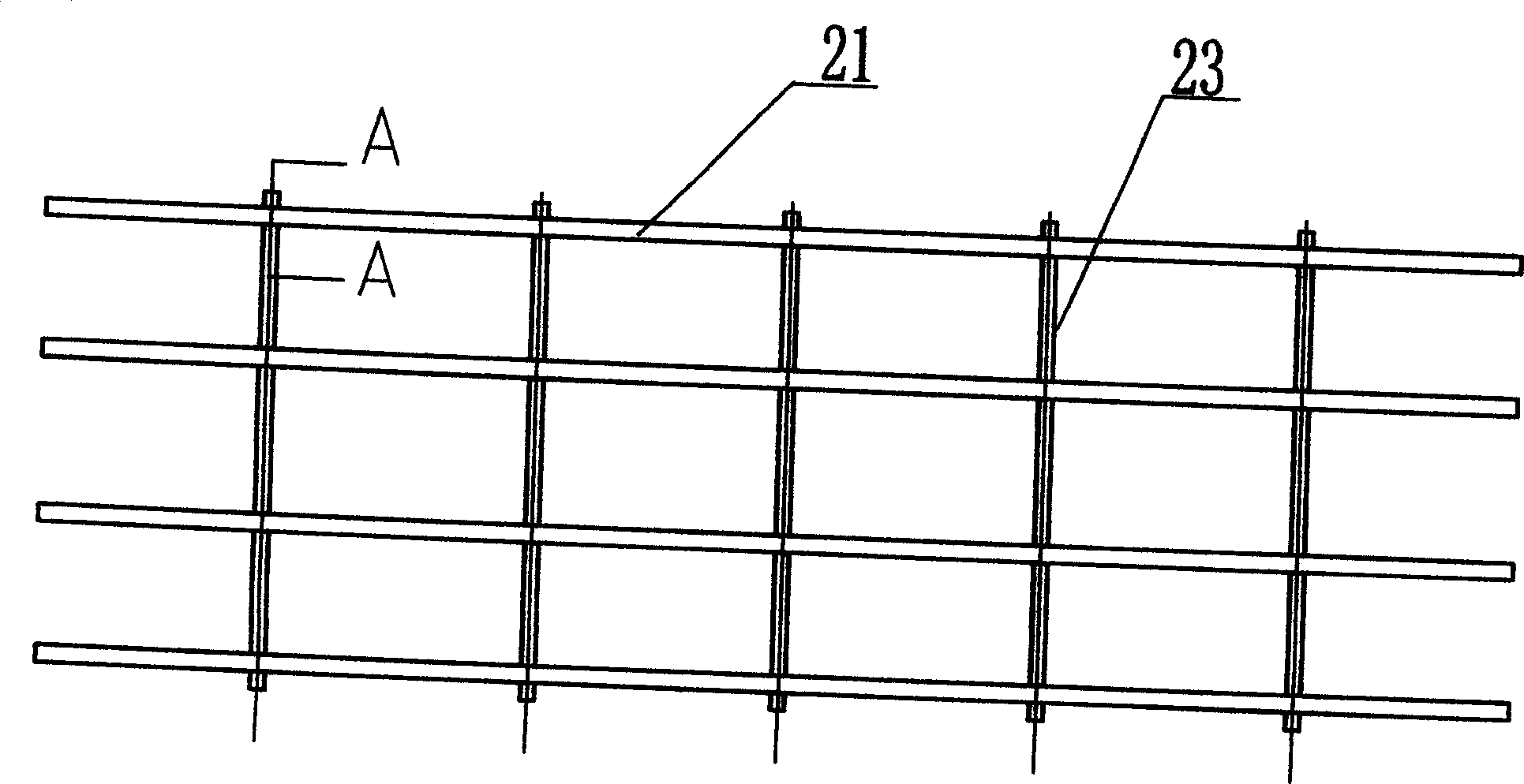

[0016] The floating energy-dissipating and noise-reducing device of the present invention is composed of a noise-reducing honeycomb panel 1, a supporting frame 2, a floating body 3 and a tightening hoop 4, and the supporting frame 2 is composed of several FRP I-shaped profiles 21, connecting rods 22 and the spacers 23 are equidistantly connected into a grid structure; the floating body 3 is a sealed tubular body, and the tubular floating body 3 is fixed below the support frame 2 by tightening the tie 4; the noise-reducing honeycomb panel 1. It is formed by splicing and bonding several pieces of PVC plastic molding boards 16. There are several special-shaped pipes with open ends on it. Each special-shaped pipe is provided with a vertical collection pipe 11 from top to bottom. Tube 12, curved surface energy dissipation tube 13, multi-stage energy dissipation groove 14 and diversion groove 15 are arranged on the curved surface energy dissipation tube 13; the cross-sectional shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com