Multilayer blasting method for bundle holes

A cluster and blast hole technology, applied in the field of cluster hole multi-layer blasting, can solve the problems of difficulty in the next blasting, clogging of blast holes, low blasting efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

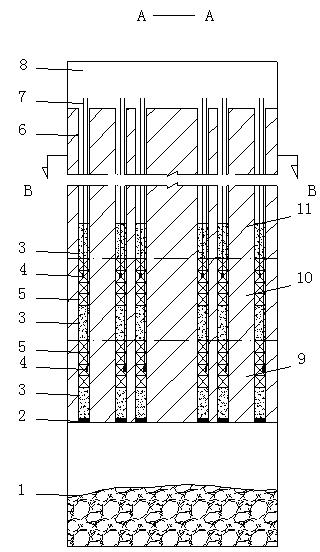

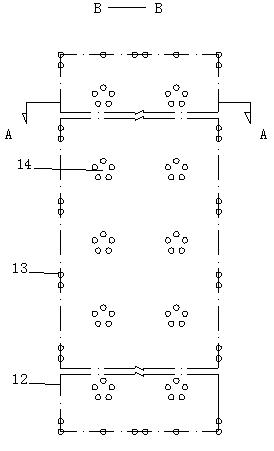

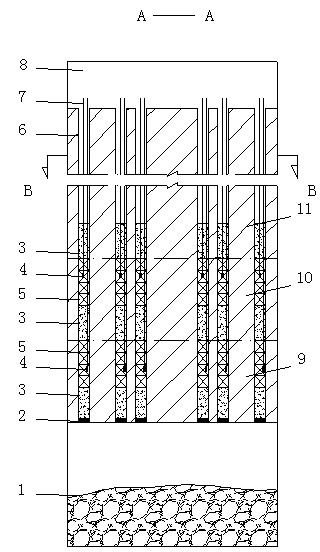

Embodiment 1

[0034] Lead-zinc ore: The thickness of the ore body is 20m, and the inclination angle is 75°, which is divided into ore blocks along the direction of the ore body. It is mined by the large-diameter deep hole open field and then filling mining method. The stope is 60m long and 20m wide; Ф165mm blastholes are used to blast vertically to drop ore, and the blasthole depth is 50m. The cluster holes in the mine house are composed of 5 blastholes, the distance between the blastholes in the beam is 0.86m, and the distance between the beams is 7.5m. Double boreholes with a spacing of 0.86m are arranged along the stope boundary, and the distance between the double boreholes is 7.5m, which are staggered from the cluster boreholes. The length of the upper, middle and lower layers of sand filling in the blast hole is all 4m, and the length of the upper and lower layers of explosive charge is 3.5m. Layer height 7.5m. The stope caving adopts two layers of caving at the same time, the deton...

Embodiment 2

[0036] XX Copper Mine: The thickness of the ore body is 30m, and the inclination angle is 35°. It is mined by the method of large-diameter deep hole open field and then filling. It is divided into ore blocks along the strike of the ore body. The width of the mine room is 12m, and the length of the mine room is 40m. Adopt Ф120mm blast hole to drop vertically deep blasting ore, and blast hole depth is 40m. The cluster hole in the mine room is composed of 8 blastholes, the distance between the blastholes in the beam is 0.5m, and the distance between the beams is 6.5m. The length of the upper, middle and lower layers of sand filling in the blast hole is all 3m, and the length of the upper and lower layers of explosive charge is 3.5m. Layer height 6.5m. The stope caving adopts two layers of caving at the same time, the detonation time of layered differential is 50 ms, and the height of one caving is 13m. Ф120mm blast holes per meter of blast holes can break 12t of ore, explosive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com