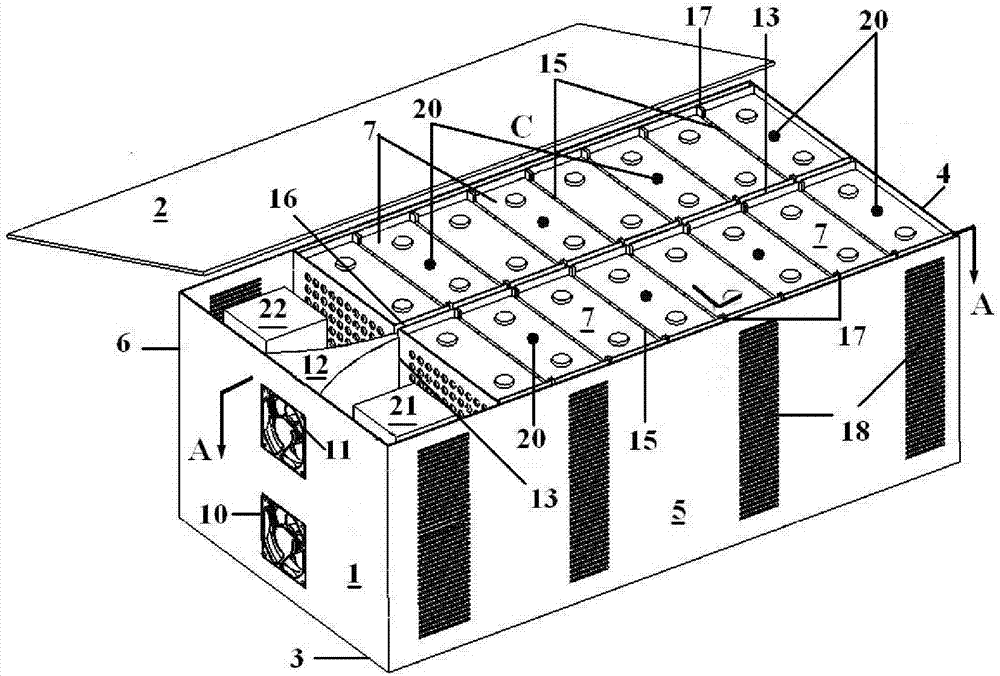

Forced air cooling battery box, and box body and cooling plates thereof

A battery cell and cold plate technology, applied in secondary batteries, battery pack parts, battery boxes/jackets, etc., can solve problems such as difficulty in meeting, corroding battery cells, and reducing the temperature difference of battery cells, and achieves a high level of improvement. Rationality, reduced erosion, reduced scour effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

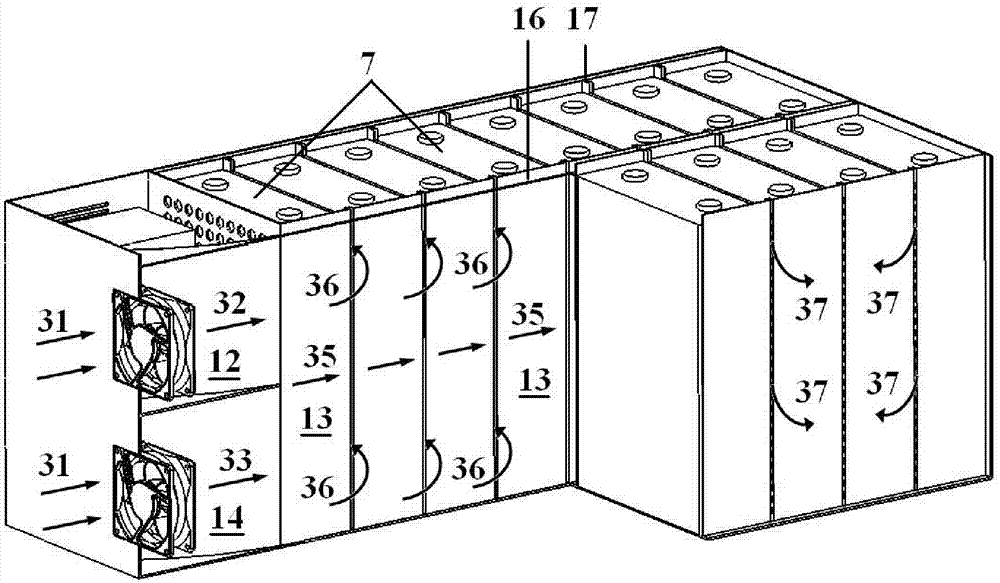

[0034] Embodiment 2 of the forced-air-cooled battery box in the present invention: The difference between this embodiment and Embodiment 1 is that the heat conduction plate surface of the panel 200 is a wavy curved surface that matches the concave-convex side of the battery cell. Specifically, the wavy curved surface It is a square wave surface to increase the heat conduction contact surface.

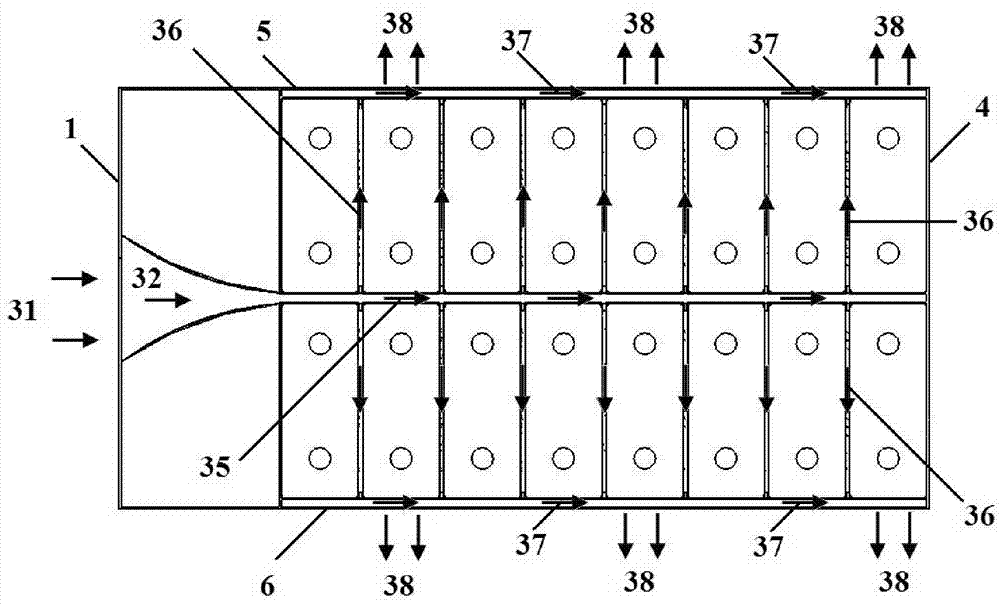

[0035] In the above embodiment, there are two rows of battery cells. In other embodiments, the battery cells can also be in one row or more than two rows. The corresponding main air duct should also be in the same row of batteries as in the above embodiment. same side of the monomer.

[0036] In the above embodiments, the cold plate is only installed in the branch air duct. In other embodiments, the cold plate can also be installed in the main air duct. connected.

[0037] In the above embodiments, the cold plate adopts a three-layer composite sandwich panel structure, and the core pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com