Method for cooling air film of turbine blade of aircraft engine

A technology for aero-engines and turbine blades, applied in the cooling of engines, cooling of turbines/propulsion devices, engine components, etc., can solve the problem of increasing cooling efficiency, difficulty in making stepwise progress, and small room for improvement of air cooling technology, etc. problems, to achieve the effect of improved cooling efficiency, easy portability and storage, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

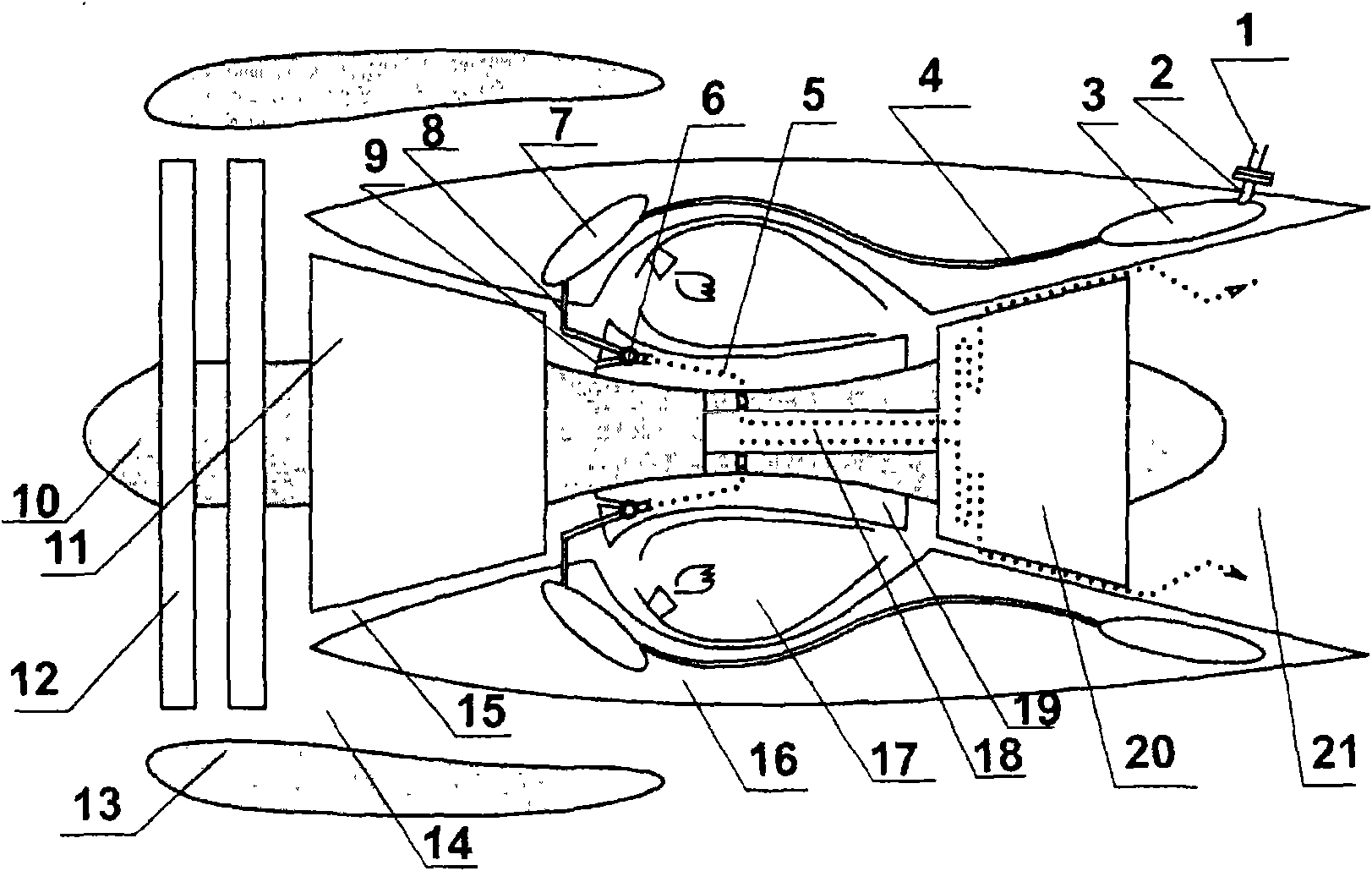

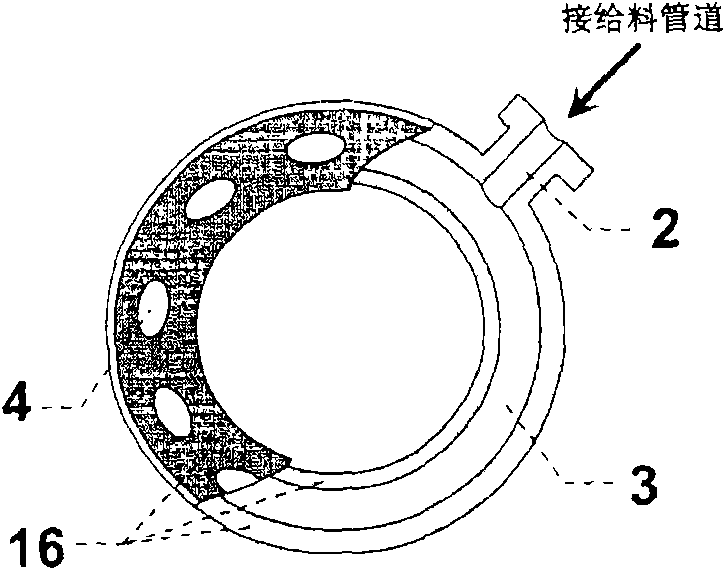

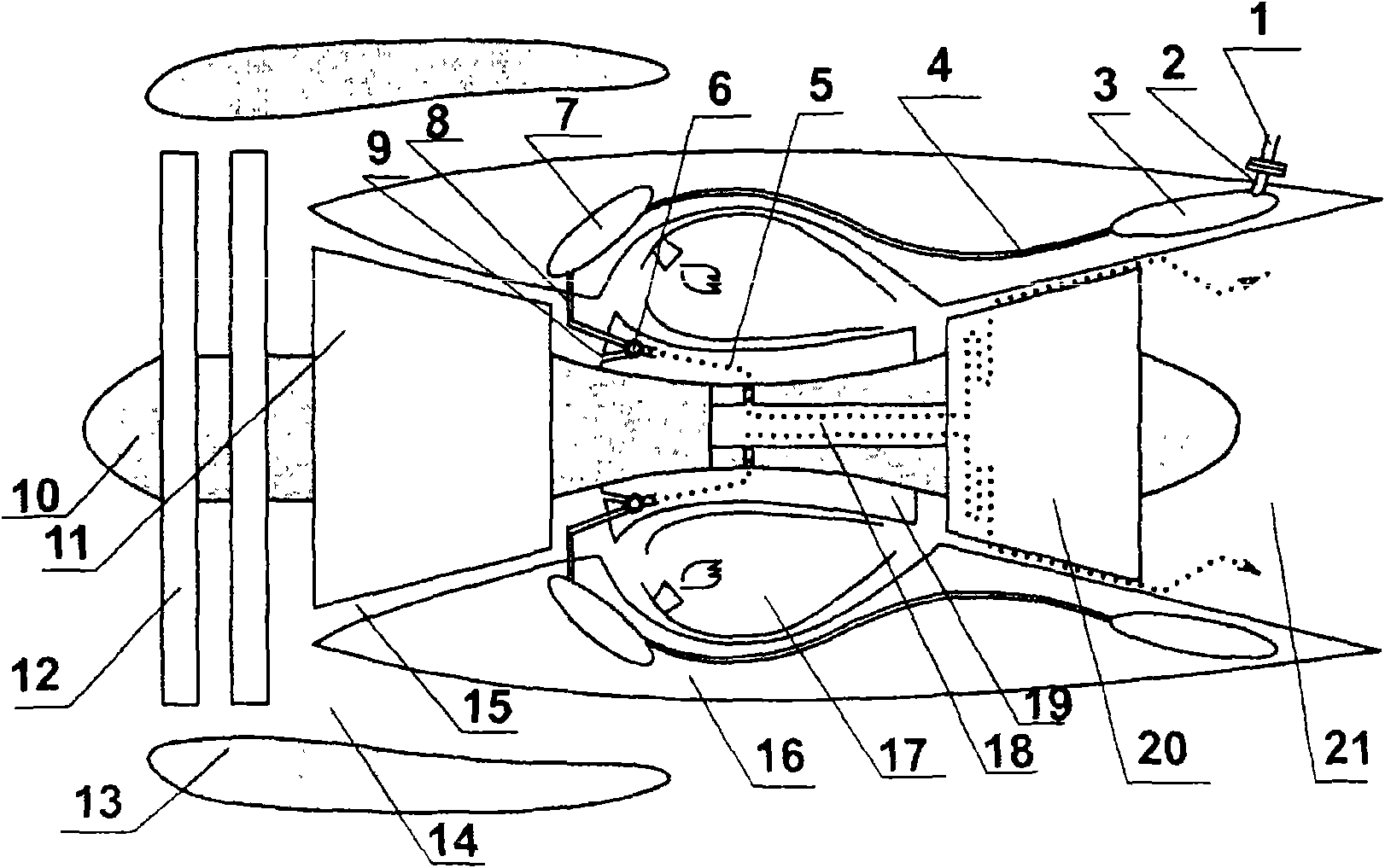

[0032] The technical scheme of the present invention uses solid working fluid as the source of cooling working medium, and the solid working medium is NH 4 HCO 3 , the cooling working fluid is its pyrolysis product, that is, NH with a volume ratio of 1:1:1 3 、H 2 O and CO 2 The mixed gas and the cooling working medium are efficiently transported from the source to the dedicated air supply channel for the cooling air of the turbine blades of the engine, and the air is replaced with the cooling working medium of the present invention, so that the film cooling method can be implemented.

[0033] The present invention can completely or partially replace air film cooling, and is applied to high-thrust and high-parameter aero turbine engines. When the amount of cooling air cannot be further increased and higher cooling efficiency must be achieved, the first-stage guide blade and the first-stage rotor blade Wait for the cooling of the aeroengine components with the highest thermal l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com