Polypropylene composite material with low linear expansion coefficient and high surface hardness and preparation method thereof

A technology of low linear expansion and composite materials, applied in the field of polypropylene composite materials, can solve problems such as complicated steps, and achieve the effects of low cost, good promotion value, low linear expansion coefficient and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

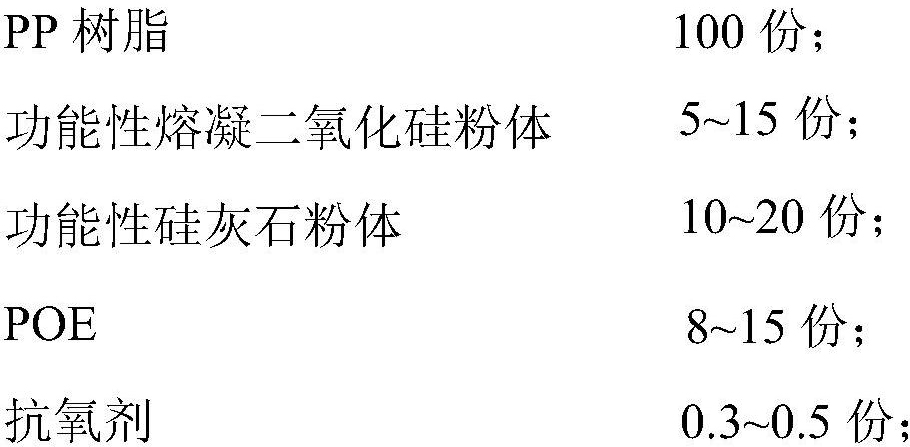

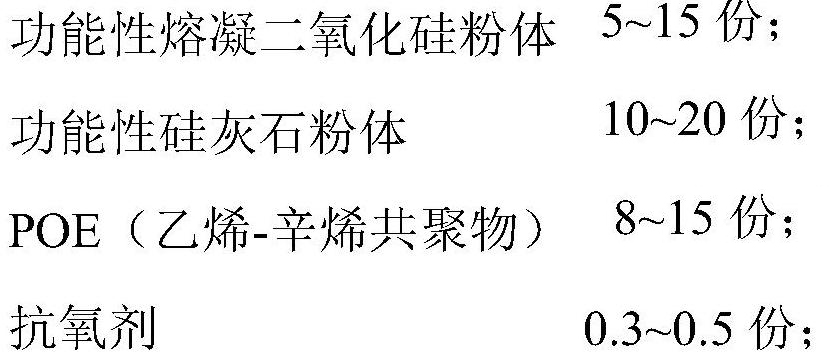

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of a polypropylene composite material with low coefficient of linear expansion and high surface hardness, comprising the steps of:

[0052] (1) Preparation of functional fused silica powder: put fused silica (FB-30 from Denki Kagaku Kogyo, Japan) and ultra-dispersed coupling agent into a high-mixer and fully mix to obtain functional fused silica powder. Condensed silica powder, wherein the weight ratio of fused silica to hyperdisperse coupling agent is 25:1, and the parameters of the high mixer are set as follows: mixing temperature 105°C, mixing time 6 minutes.

[0053] Preparation of functional wollastonite powder: put wollastonite (AT-28 from Jiangxi Aote) and super-dispersed coupling agent produced by Shanghai Zhehua into a high-mixer and fully mix to obtain functional wollastonite powder ; Wherein, the weight ratio of wollastonite and ultra-dispersed coupling agent is 20:1, and the parameters of the high mixer are set as follows: the mixing tem...

Embodiment 2

[0059] A preparation method of a polypropylene composite material with low coefficient of linear expansion and high surface hardness, comprising the steps of:

[0060] (1) Preparation of functional fused silica powder: put fused silica (FB-35 from Denki Kagaku Kogyo, Japan) and hyperdisperse coupling agent into a high-mixer and fully mix to obtain functional fused silica powder. Condensed silica powder, wherein the weight ratio of fused silica to hyperdisperse coupling agent is 26:1, and the parameters of the high mixer are set as follows: mixing temperature 108°C, mixing time 6 minutes.

[0061] Preparation of functional wollastonite powder: put wollastonite (W61-60 produced by Suzhou Haicheng Minerals Co., Ltd.) and ultra-dispersed coupling agent produced by Shanghai Zhehua into a high-mixer and fully mix to obtain functional wollastonite powder body; wherein, the weight ratio of wollastonite to hyperdisperse coupling agent is 24:1, and the parameters of the high mixer are s...

Embodiment 3

[0067] A preparation method of a polypropylene composite material with low coefficient of linear expansion and high surface hardness, comprising the steps of:

[0068] (1) Preparation of functional fused silica powder: put fused silica (FB-30 from Denki Kagaku Kogyo, Japan) and ultra-dispersed coupling agent into a high-mixer and fully mix to obtain functional fused silica powder. Condensed silica powder, wherein the weight ratio of fused silica to hyperdisperse coupling agent is 28:1, and the parameters of the high mixer are set as follows: mixing temperature 109°C, mixing time 6 minutes.

[0069] Preparation of functional wollastonite powder: put wollastonite (AT-28 from Jiangxi Aote) and super-dispersed coupling agent produced by Shanghai Zhehua into a high-mixer and fully mix to obtain functional wollastonite powder ; Wherein, the weight ratio of wollastonite and ultra-dispersed coupling agent is 23:1, and the parameters of the high mixer are set as follows: the mixing tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com