Thread joint structure for high-performance oil casing

A high-performance, threaded connection technology, used in threaded connections, pipes/pipe joints/fittings, casings, etc., can solve the problems of difficult processing of special threaded connection maintenance accessories, high import costs, and restrictions on the use of special buckle casings. To maximize the connection efficiency, optimize the design of the thread structure, and optimize the compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

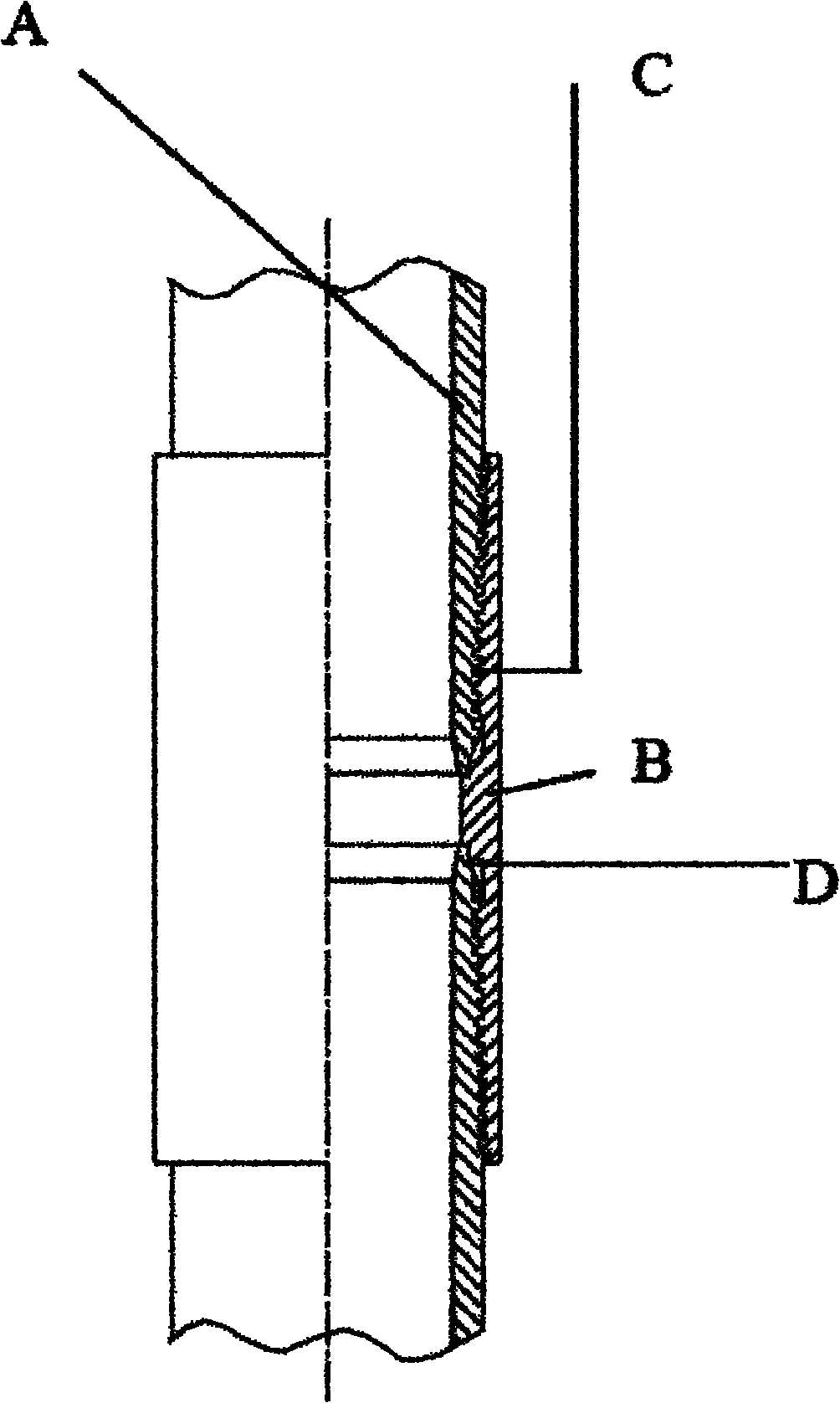

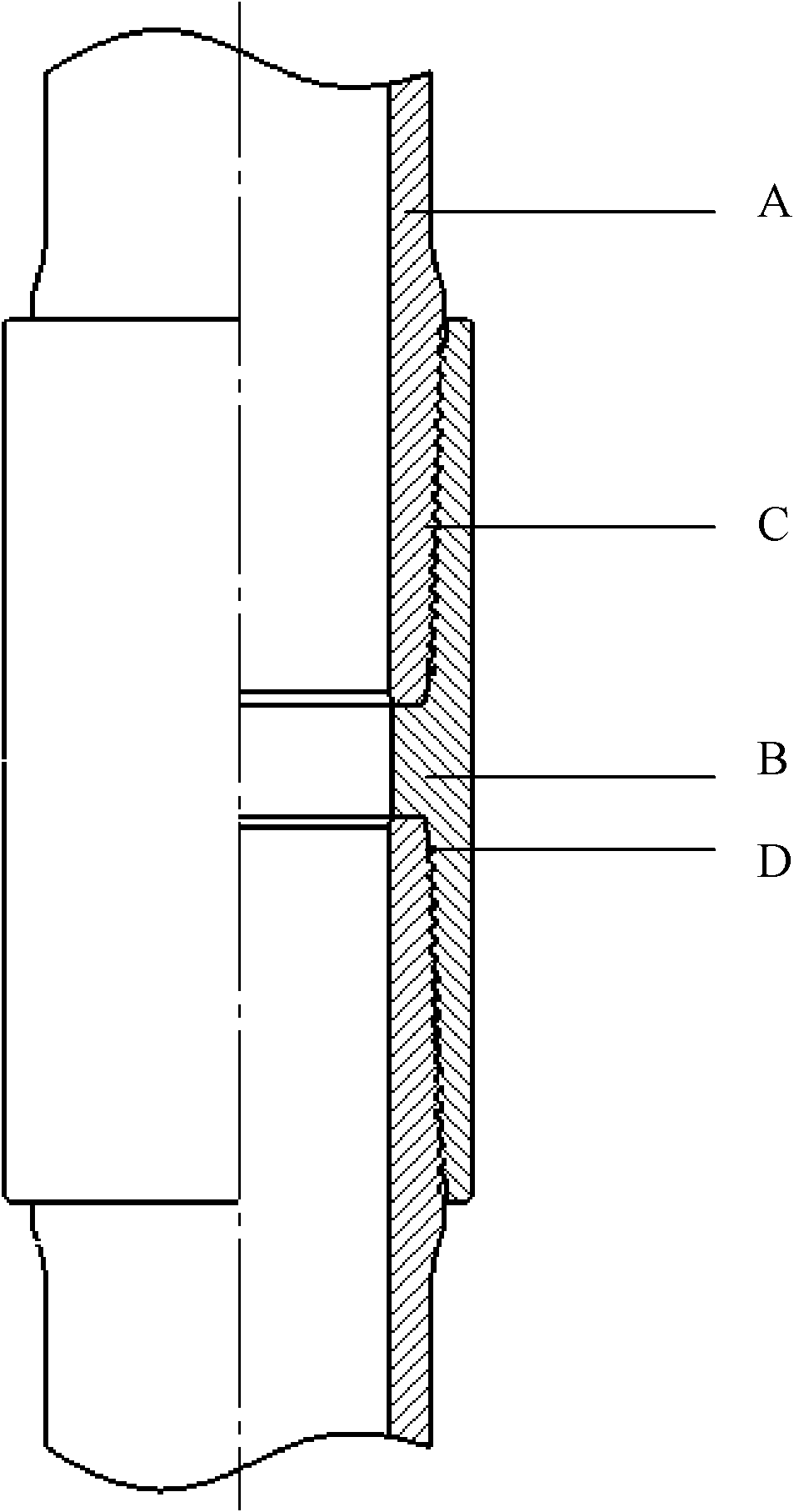

[0014] The air-tight screw connection structure of the high-performance casing of the present invention will be described with reference to the accompanying drawings and embodiments.

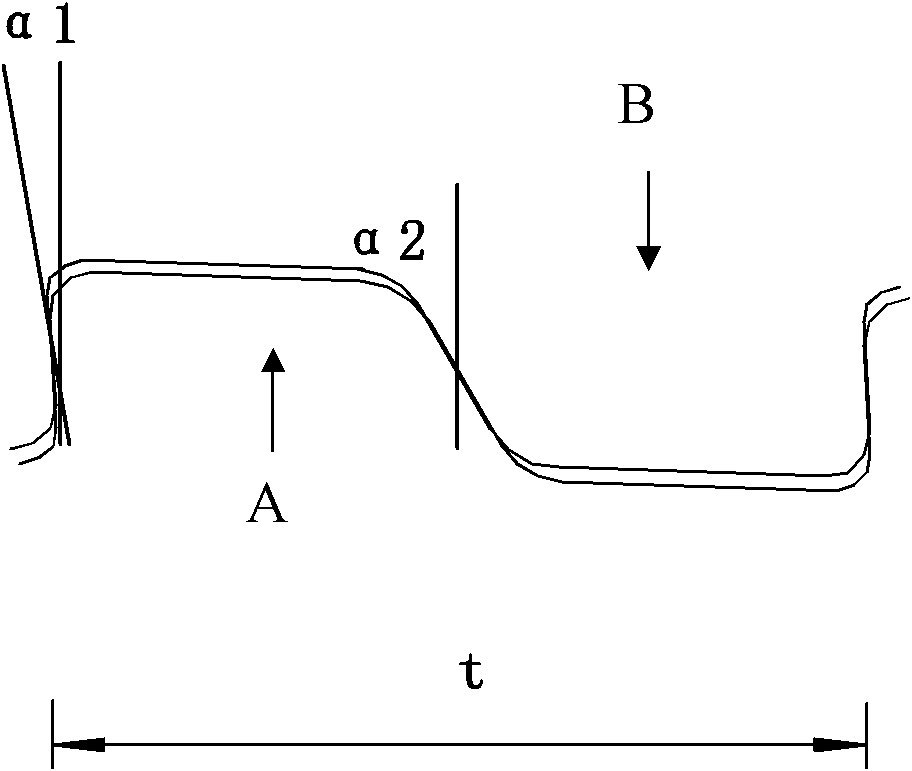

[0015] The threaded joint structure of the high-performance oil casing pipe of the present invention comprises a casing with an external thread at its end and a coupling with an internal thread. The external thread at the end of the casing The internal threads of the coupling and the coupling are both negative-angle taper threads. The thread is designed with tooth flank interference, and the tooth flank interference is 5mm to 25.4mm in the axial direction. The internal thread of the coupling is provided with a torque stop shoulder, and the internal holes of the male and female ends of the screwed joint are flush.

[0016] The tooth profile of the negative angle taper thread is: the thread is designed to have a tooth side interference, the load side angle is -2 to -5, the pitch of the tooth profile is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com