Powder concentrator integrating functions of scattering, drying and grading into whole

A technology that integrates powder separation and powder separators, and is applied in the directions of drying, drying solid materials, and heating to dry solid materials, etc. It can solve the problems that affect the stability of the powder selection efficiency of the powder separator, the material is scattered and the drying effect is not good. , affecting the dispersion effect of viscous and wet materials, etc., to achieve the effect of prolonging the drying and breaking up path, clear drying and grading path, and good sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

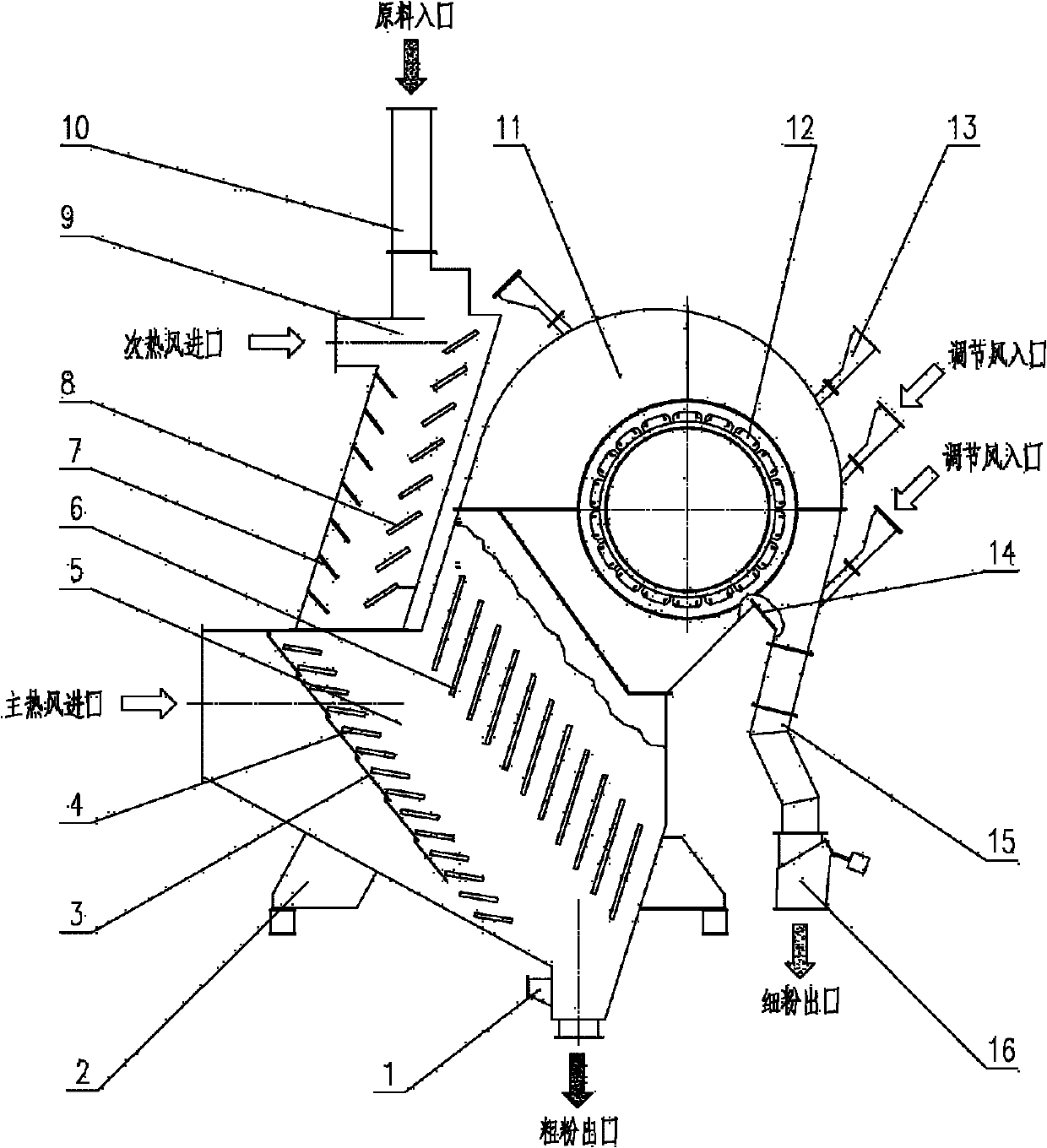

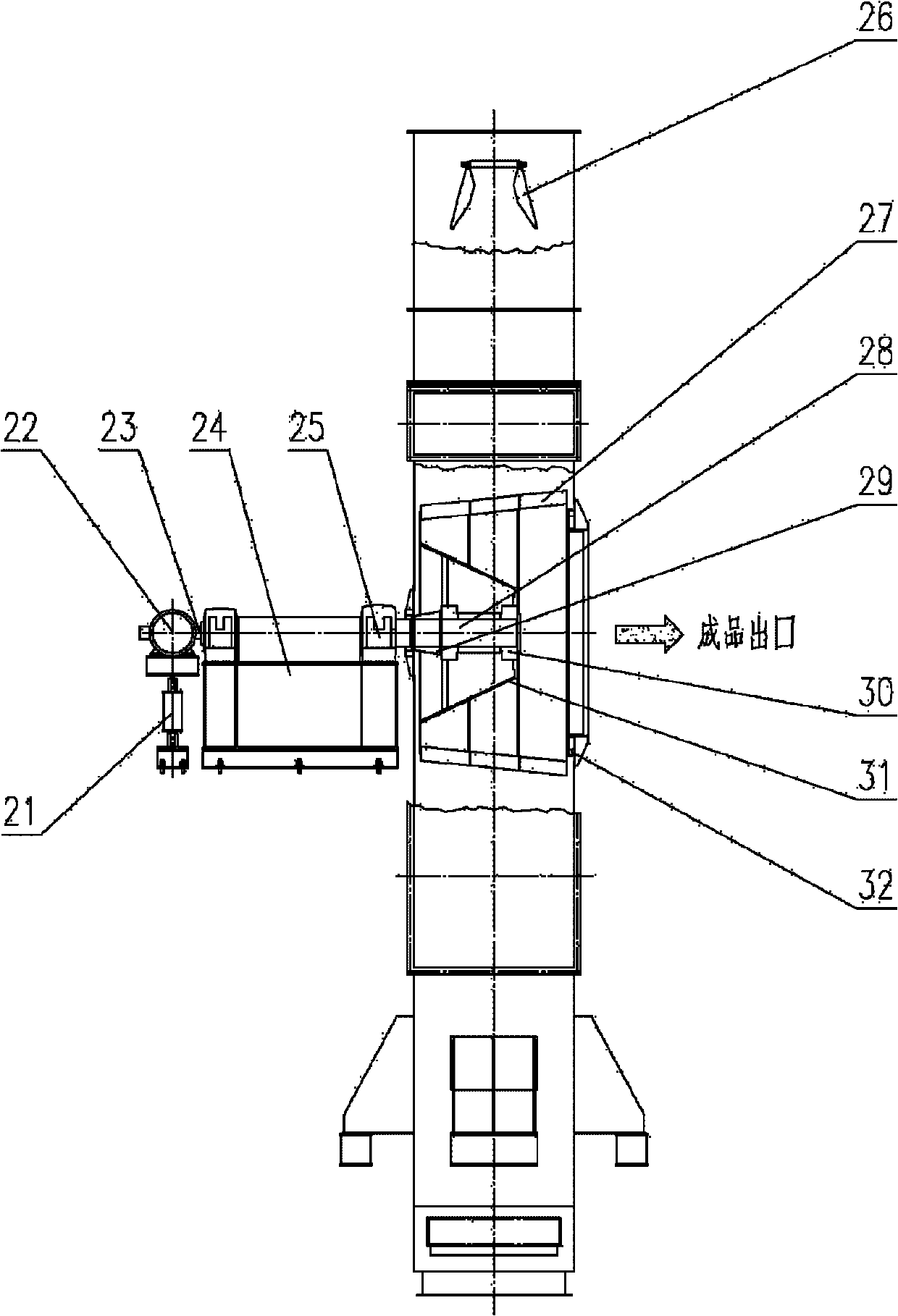

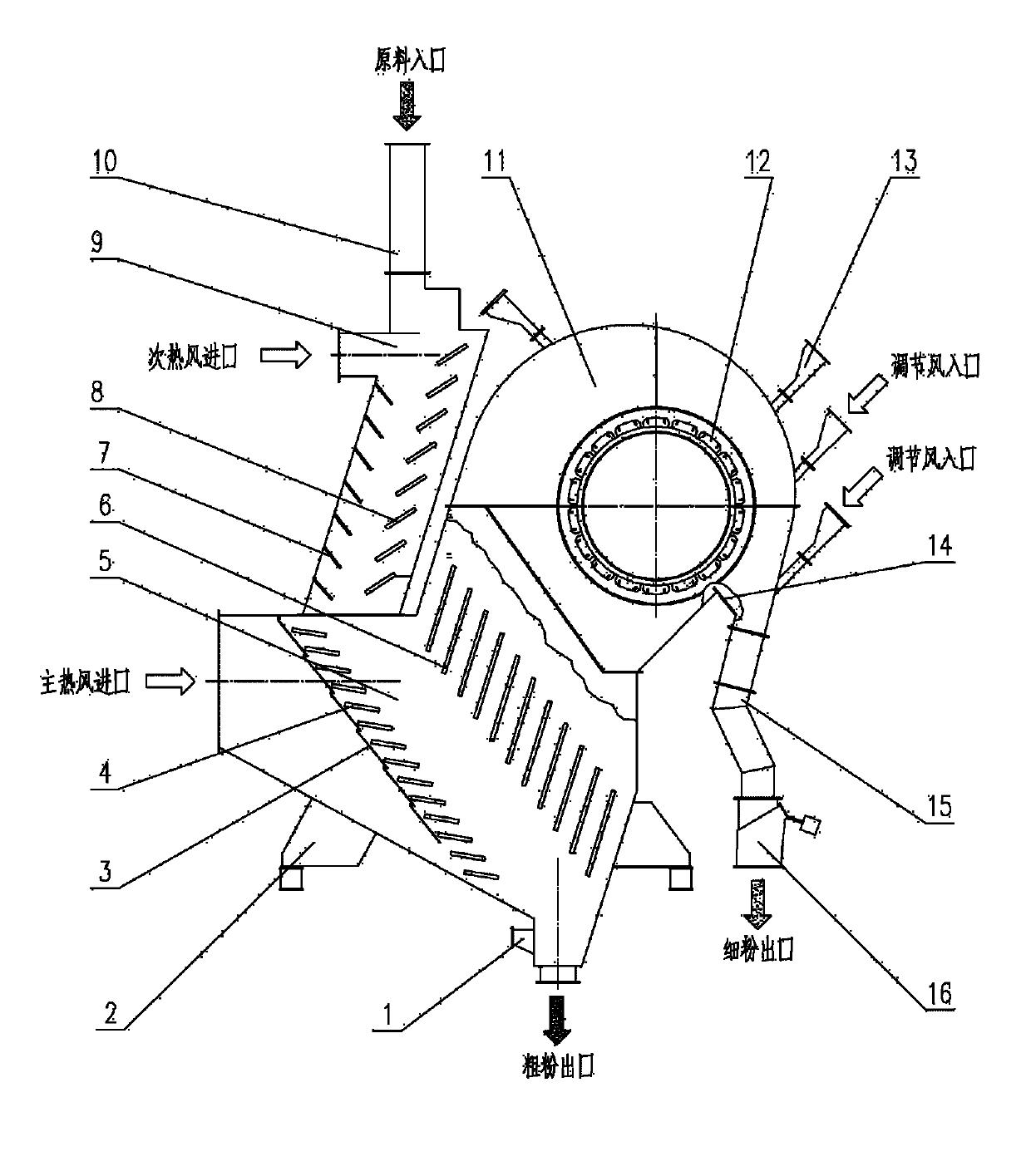

[0022] In order to further understand the invention content, characteristics and effects of the present utility model, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings: Please refer to figure 1 and figure 2 , the present invention is mainly made up of drying zone housing 6, breaking up zone housing 10, raw material distribution pipe 12, material distribution device 23, volute case 13, classifying rotor 29, main shaft 25 and main bearing bracket 22. The drying zone casing 6 is a "V"-shaped structure, and the upper part of one side is connected with a rectangular dispersing zone casing 10 arranged obliquely, with an inclination angle of 45°-90°. The upper part of the shell 10 of the breaking up area is connected with a raw material distributing pipe 12 with a distributing device 23 inside, and the upper opening of the raw material distributing pipe 12 is a raw material inlet. The shell part of the dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com