Method for producing carbon fiber-completely winded composite gas cylinder with aluminum inner container

A production process, carbon fiber technology, applied in the field of aluminum liner carbon fiber full-wound composite gas cylinders, can solve the problems of corrosion resistance, poor safety gas cylinders, debris flying out and hurting people, safety performance, fatigue life, corrosion resistance, fire resistance Poor performance and poor breath-holding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

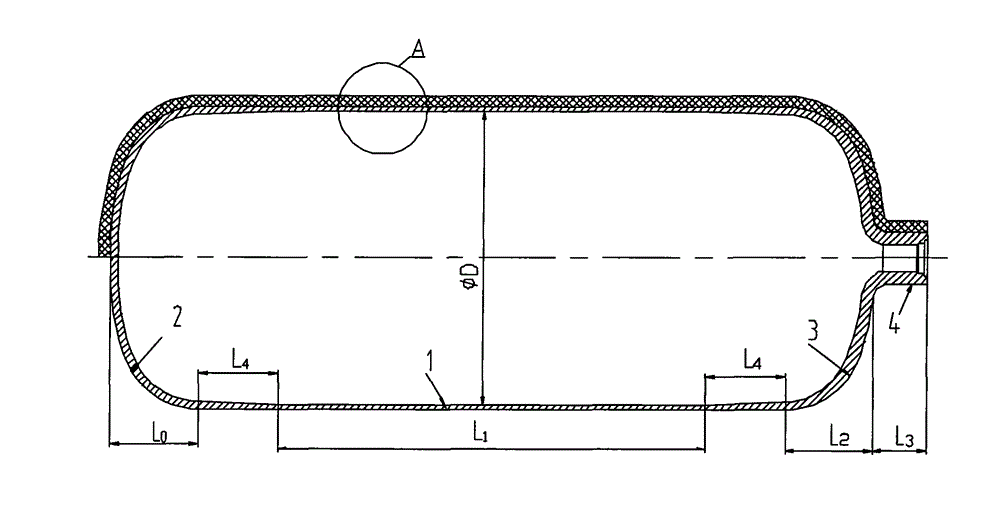

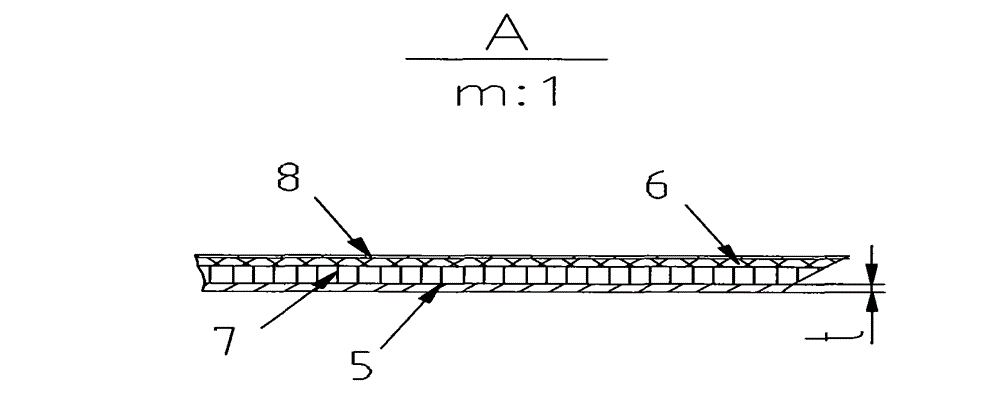

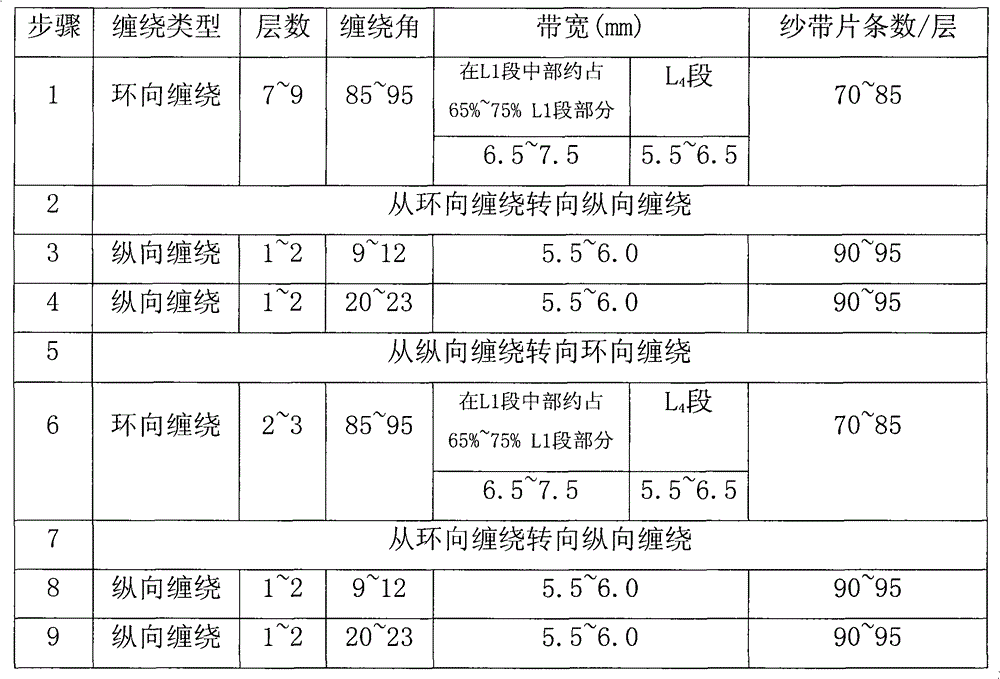

[0024] Aluminum liner carbon fiber fully wound composite gas cylinder includes bottle bottom part 2, cylinder part 1, bottle shoulder part 3 and bottle mouth part 4, and its main load-bearing structure is composed of aluminum liner and carbon fiber winding layers 6 and 7, the structure is as follows figure 1 As shown, according to its functional requirements, the present invention uses composite material structure finite element analysis to optimize the design of the layering sequence of the aluminum liner carbon fiber fully wound composite gas cylinder, such as figure 2 As shown, the seamless aluminum liner is used as the core mold, and the T700-12KC carbon fiber is wound on the surface of the aluminum liner according to the optimally designed layer sequence, and the glass fiber is wound on the outer surface as the impact protection layer 8, and in the manufacturing process Carry out "self-tightening" treatment on the composite gas cylinder, the specific implementation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com