Cloth re-winding rubber pipe of fluororubber and silicon rubber composite extrusion and preparation method thereof

A silicone rubber and fluororubber technology is applied in the field of turbocharged hoses for heavy-duty vehicles, which can solve the problems that the pulse performance cannot meet the standard requirements and the turbocharged hoses are difficult to use for a long time, and achieve the effect of increasing the service life and increasing the burst pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

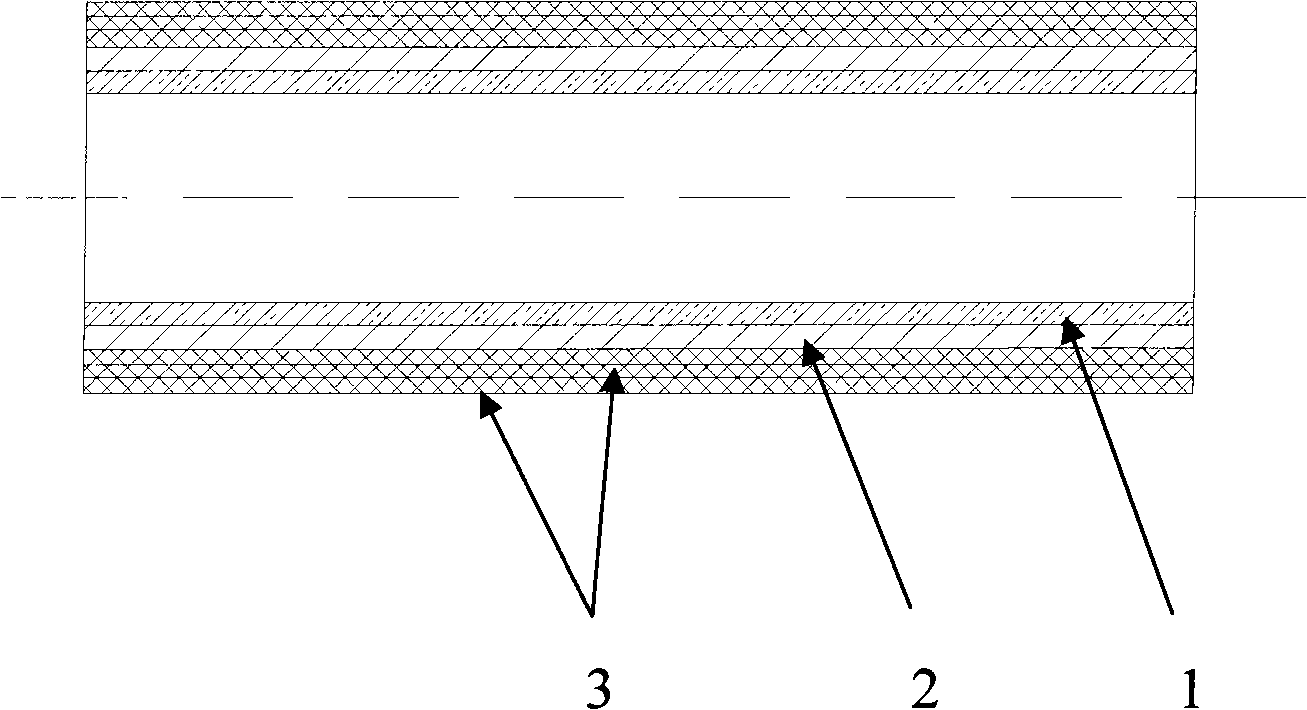

[0023] produce a figure 1 For the turbocharger hose with an inner diameter of 50±0.5mm×5±0.5mm×400±3mm, the steps are as follows:

[0024] 1) Tube embryo manufacturing process

[0025] Extrude inner rubber and middle rubber: Extrude fluorine rubber and silica gel on the dual compound extruder at the same time, set the extrusion temperature of inner rubber fluorine rubber to 60°C from the machine head, extrusion section, plasticizing section, feeding section, and screw ℃, 50℃, 50℃, 50℃, 50℃, the extrusion temperature of medium rubber silicone is 40℃, 30℃, 30℃, 30℃ from the machine head, extrusion section, plasticizing section, feeding section and screw. °C, 30 °C. The thickness of fluorine rubber is controlled at 0.8mm, and the thickness of silica gel is controlled at 1.2mm.

[0026] The reinforcement layer adopts a composite structure of silica gel and cloth.

[0027] Production of silicone cloth: Cut the cloth according to the size of the silicone tube product, set the th...

Embodiment 2

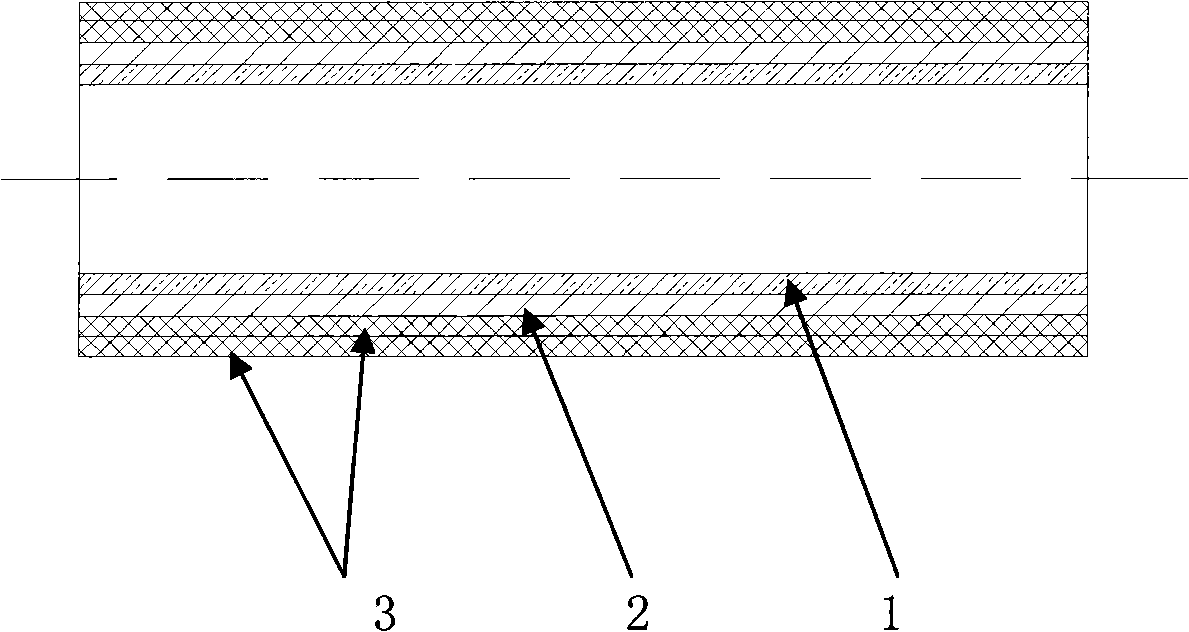

[0033] produce as figure 2 The shown inner diameter is 60 ± 1 mm × 4.5 ± 0.5 mm × 600 ± 3 mm turbocharger hose, the method steps are as shown in Example 1, the difference is:

[0034] 1) Tube embryo manufacturing process

[0035] Set the extrusion temperature of inner rubber fluoro rubber to 80°C, 70°C, 70°C, 70°C, 70°C from machine head, extrusion section, plasticizing section, feeding section, and screw, and the extrusion temperature of medium rubber silicone from The machine head, extrusion section, plasticizing section, feeding section and screw are all at 50°C, 40°C, 40°C, 40°C, 40°C. The thickness of fluorine rubber is controlled at 0.8mm, and the thickness of silica gel is controlled at 1.2mm.

[0036] Production of silicone cloth: Cut the cloth according to the size of the silicone tube product, and set the thickness of the silicone cloth to 1.2mm.

[0037] 2) Vulcanization molding process:

[0038] Put the semi-finished product of fluorine rubber and silicone tub...

Embodiment 3

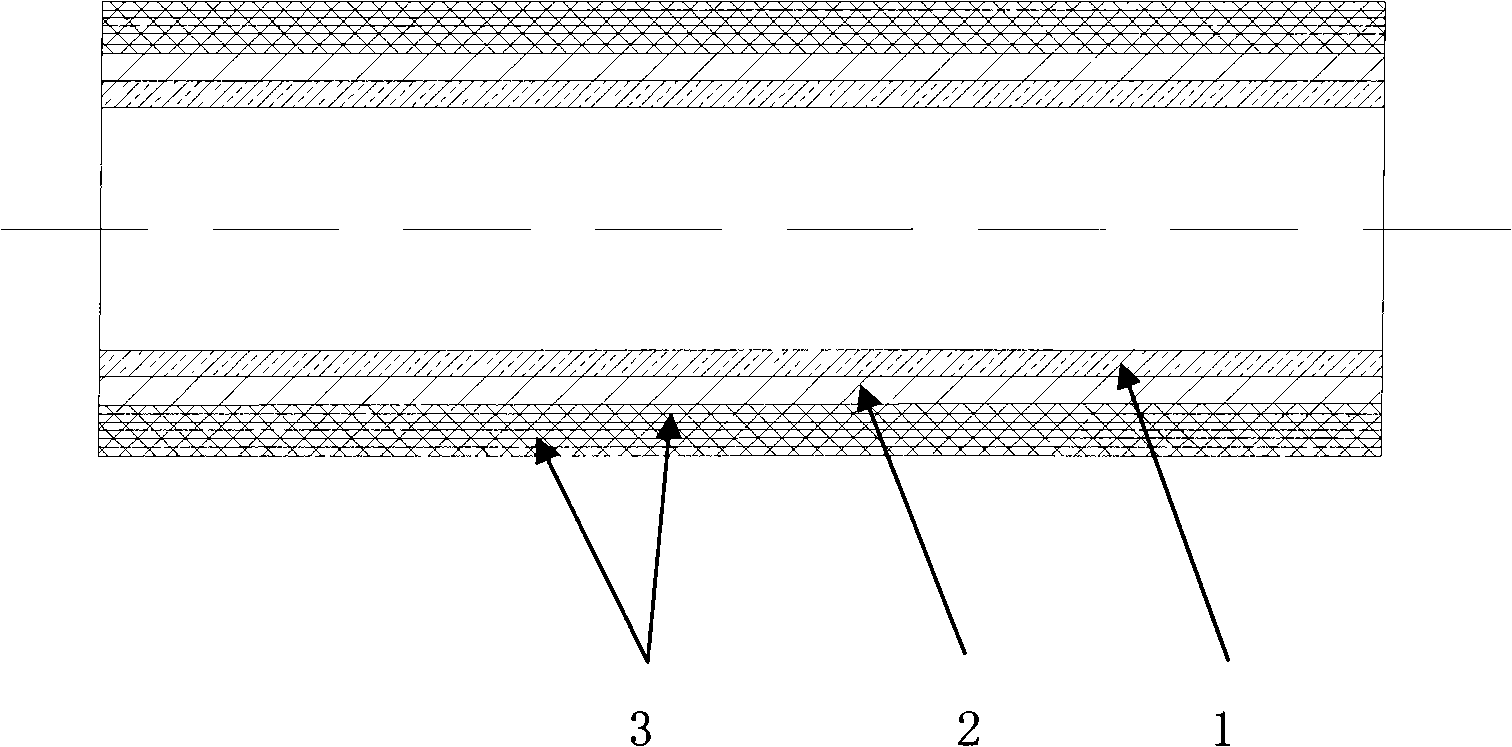

[0043] produce as image 3 The turbocharged rubber hose with an inner diameter of 70±1mm×8.5±0.5mm×400±3mm, the method steps are as shown in Example 1, the difference is:

[0044] Set the extrusion temperature of inner rubber fluoro rubber to 50°C, 40°C, 40°C, 40°C, 40°C from the machine head, extrusion section, plasticizing section, feeding section, and screw, and the extrusion temperature of medium rubber silicone from The machine head, extrusion section, plasticizing section, feeding section and screw are all at 20°C, 20°C, 20°C, 20°C, 20°C. The thickness of fluorine rubber is controlled at 1mm, and the thickness of silica gel is controlled at 1.5mm.

[0045] Production of silicone cloth: Cut the cloth according to the size of the silicone tube product, and set the thickness of the silicone cloth to 1.0mm.

[0046] 3) Vulcanization molding process:

[0047] Put the semi-finished product of fluorine rubber and silicone tube after double-compound extrusion on the mandrel, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com