Water supply and drainage mechanism at pool bottom of assembly type swimming pool.

A prefabricated, water supply and drainage technology, which is applied in swimming pools, public buildings, gymnasiums, etc., can solve problems such as turbulent water flow in pools, inability to drain water in drainage pools, poor puncture resistance and frost resistance of adhesive films, and achieve easy The effect of widening and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

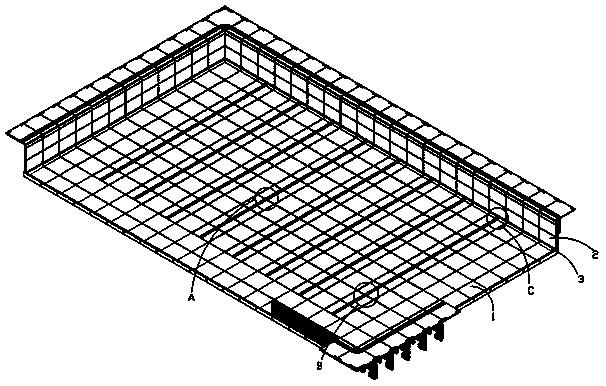

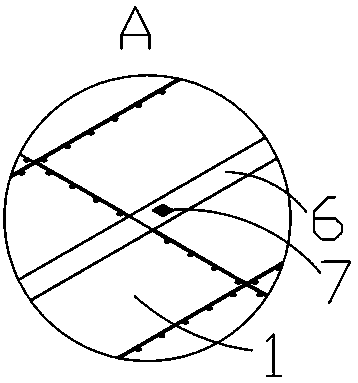

[0020] Embodiment one: if figure 1 , figure 2 , Figure 4 As shown, a prefabricated swimming pool bottom water supply and drainage mechanism includes a swimming pool bottom formed by splicing several pool bottom plates 1, an inner wall 2 vertically arranged around the bottom of the swimming pool, and connected to the swimming pool. The pool edge plate 3 between the edge of the pool bottom and the lower edge of the inner wall plate 2, the connection between the inner wall plate 2 and the adjacent inner wall plate 2 or the pool edge plate 3, the A sealing structure is provided between the pool bottom plate 1 and the adjacent pool bottom plate 1 or the pool side plate 3, the sealing structure can be installed with sealant or a sealing strip is set between the two, the same row or In the same row, the pool bottom plate 1 and the pool side plate 3 are provided with a water supply / drainage groove 4, and the outer side of the inner wall plate 2 is provided with a water supply pipe...

Embodiment 2

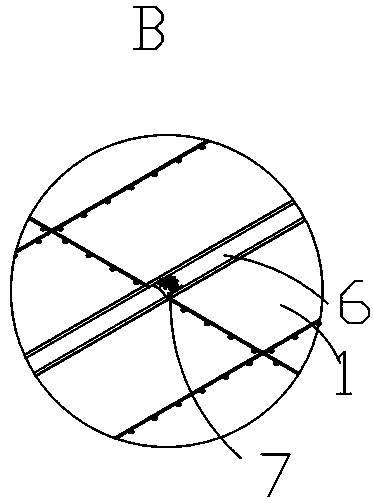

[0025] Embodiment two, such as image 3 As shown, the difference from Embodiment 1 is that the cover plate 6 is an arc-shaped plate, and the structure of the arc-shaped plate makes the swimming pool drain more thoroughly without causing residual phenomenon, which greatly facilitates the water exchange work of the swimming pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com