Plant laser lighting fluorescent glass-ceramics and preparation method thereof

A technology of laser lighting and glass-ceramics, which is applied in the field of solid luminescent materials, can solve the problems of deterioration of organic materials, poor thermal stability and chemical stability, etc., and achieves the effects of good thermal stability, low cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

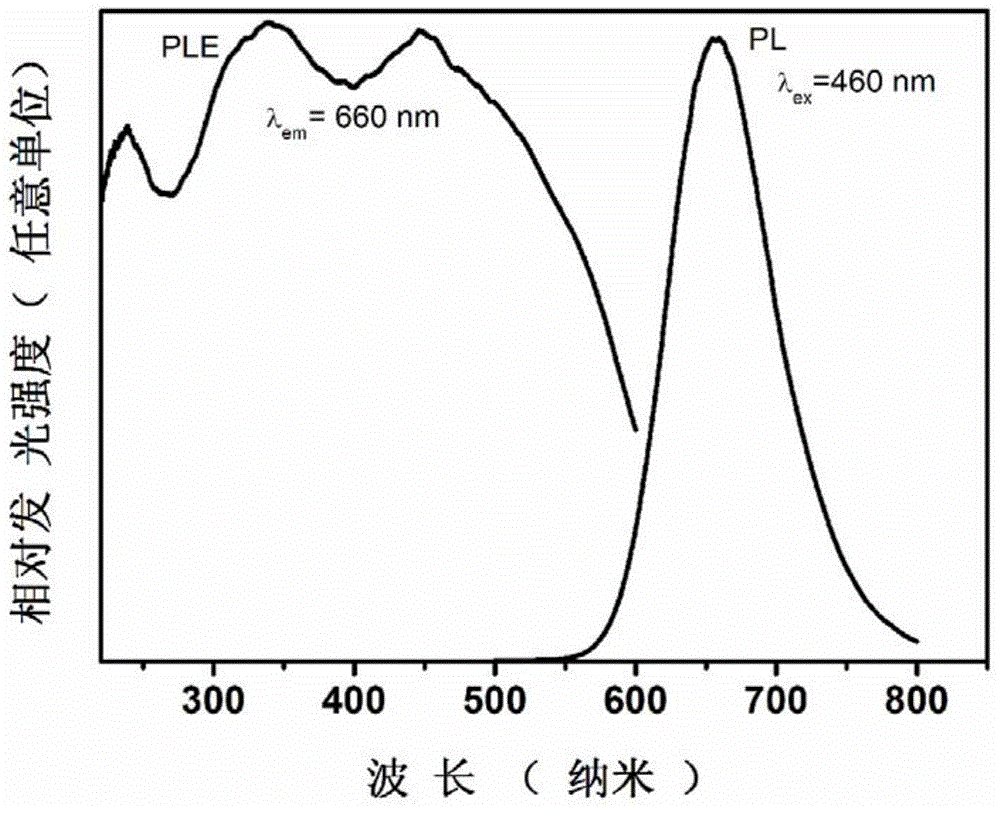

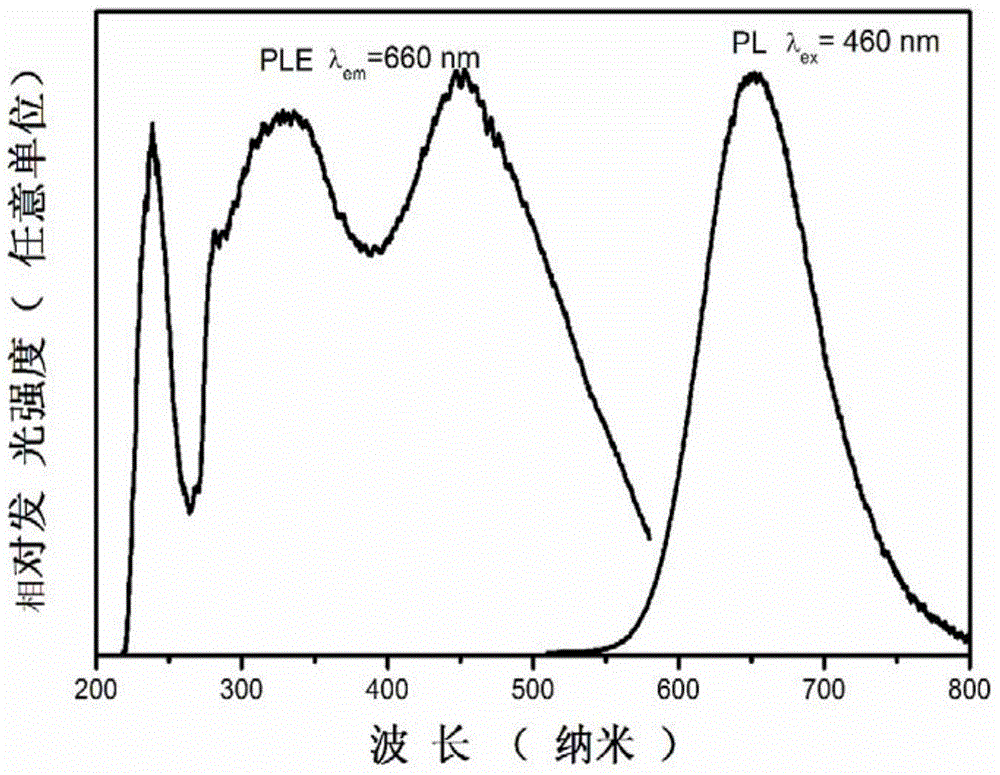

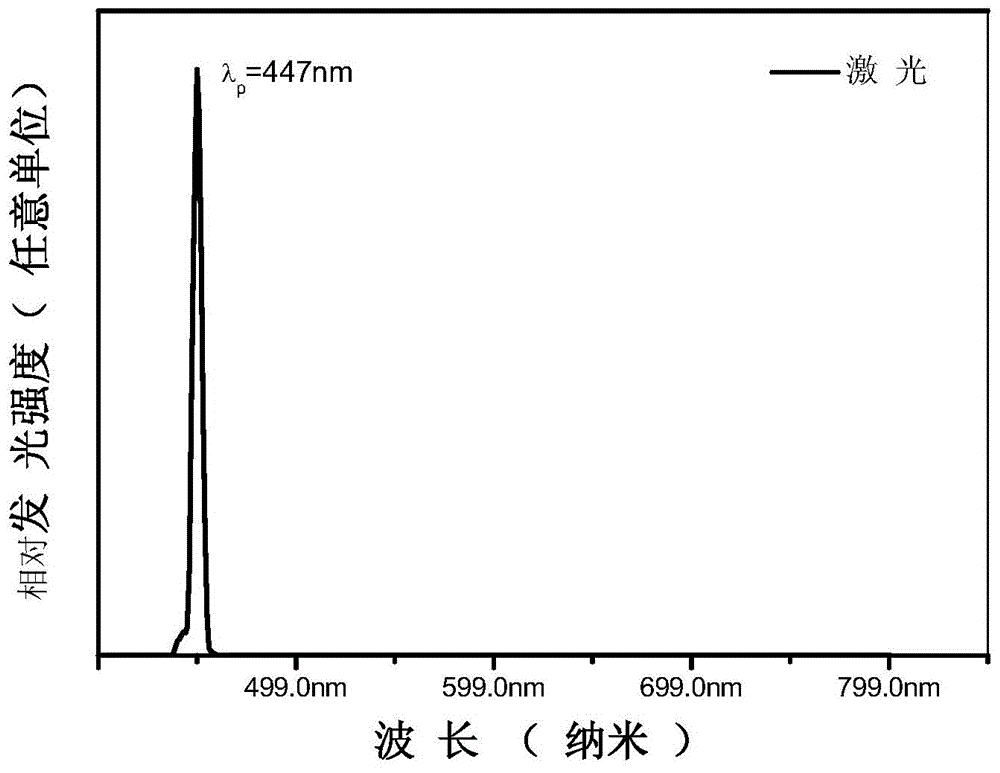

[0019] A fluorescent glass-ceramic for plant laser lighting, which is composed of a glass matrix and a red phosphor, wherein the content of the red phosphor is 10wt%, and the glass matrix is 90wt%; the composition of the glass matrix is: 10wt% SiO 2 , 10wt% La 2 o 3 , 80 wt% B 2 o 3 ; The red phosphor is CaAlSiN 3 : Eu 2+ , which emits 660nm broad-spectrum deep red light under the excitation of a blue laser light source, with a full width at half maximum of 80nm; the red phosphor crystal grains are evenly embedded in the glass matrix.

[0020] The preparation method of the fluorescent glass-ceramics for plant laser lighting, the steps are as follows:

[0021] 1) put B 2 o 3 , SiO 2 , La 2 o 3 Add the powder into the crucible according to the proportion, put it into the resistance furnace and heat it to 1300°C, then keep it warm for 120 minutes until it is completely melted, quickly pour the molten glass at 1000°C and press it into a glass sheet, and anneal the glas...

Embodiment 2

[0025] A fluorescent glass-ceramic for plant laser lighting, which is composed of a glass matrix and a red phosphor, wherein the content of the red phosphor is 20wt%, and the glass matrix is 80wt%; the composition of the glass matrix is: 20wt% SiO 2 , 10wt% La 2 o 3 , 70 wt% B 2 o 3 ; The red phosphor is CaAlSiN 3 : Eu 2+ , which emits 660nm broad-spectrum deep red light under the excitation of a blue laser light source, with a full width at half maximum of 80nm; the red phosphor crystal grains are evenly embedded in the glass matrix.

[0026] The preparation method of the fluorescent glass-ceramics for plant laser lighting, the steps are as follows:

[0027] 1) put B 2 o 3 , SiO 2 , La 2 o 3 Add the powder into the crucible according to the proportion, put it into the resistance furnace and heat it to 1100°C, then keep it warm for 60 minutes until it is completely melted, pour the molten glass liquid into clean water at 900°C and quench it into glass particles. A...

Embodiment 3

[0031] A fluorescent glass-ceramic for plant laser lighting, which is composed of a glass matrix and a red phosphor, wherein the content of the red phosphor is 15wt%, and the glass matrix is 85wt%; the composition of the glass matrix is: 15wt% SiO 2 , 5wt% La 2 o 3 , 80 wt% B 2 o 3 ; The red phosphor is CaAlSiN 3 : Eu 2+ , which emits 660nm broad-spectrum deep red light under the excitation of a blue laser light source, with a full width at half maximum of 80nm; the red phosphor crystal grains are evenly embedded in the glass matrix.

[0032] The preparation method of the fluorescent glass-ceramics for plant laser lighting, the steps are as follows:

[0033] 1) put B 2 o 3 , SiO 2 , La 2 o 3 Add the powder into the crucible according to the proportion, put it into the resistance furnace and heat it to 1300°C, then keep it warm for 60 minutes until it is completely melted, quickly pour the molten glass at 1000°C and press it into a glass sheet, and anneal the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com