Air conditioner air supply and air return system for plant factory

A wind system and plant technology, applied in the field of air-conditioning return air system for plant factories, can solve problems such as uneven temperature/humidity, fatal injuries, and affecting the homogeneous production of "plant factories", achieving uniform temperature/humidity, Reduce the effect of the initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

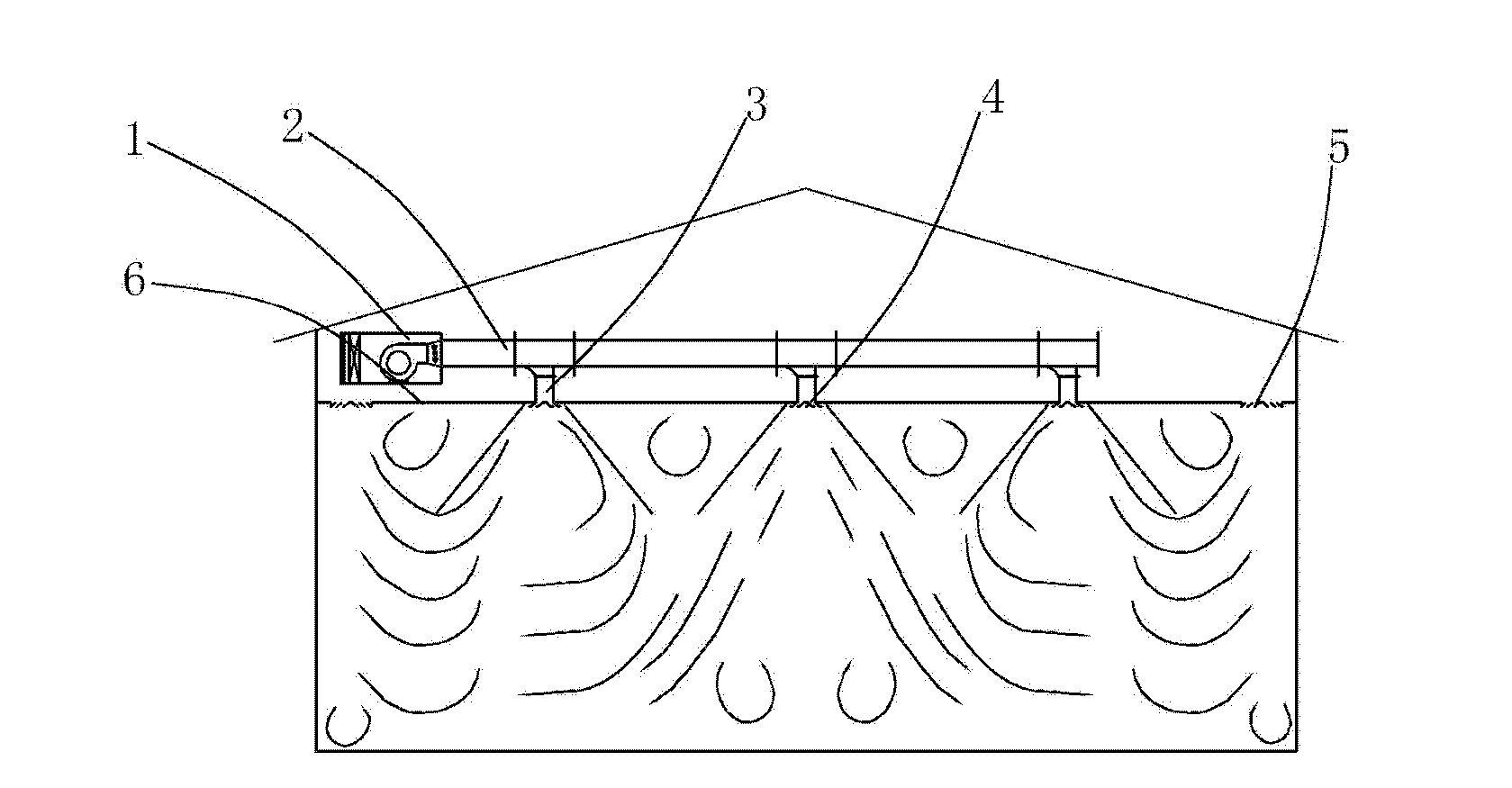

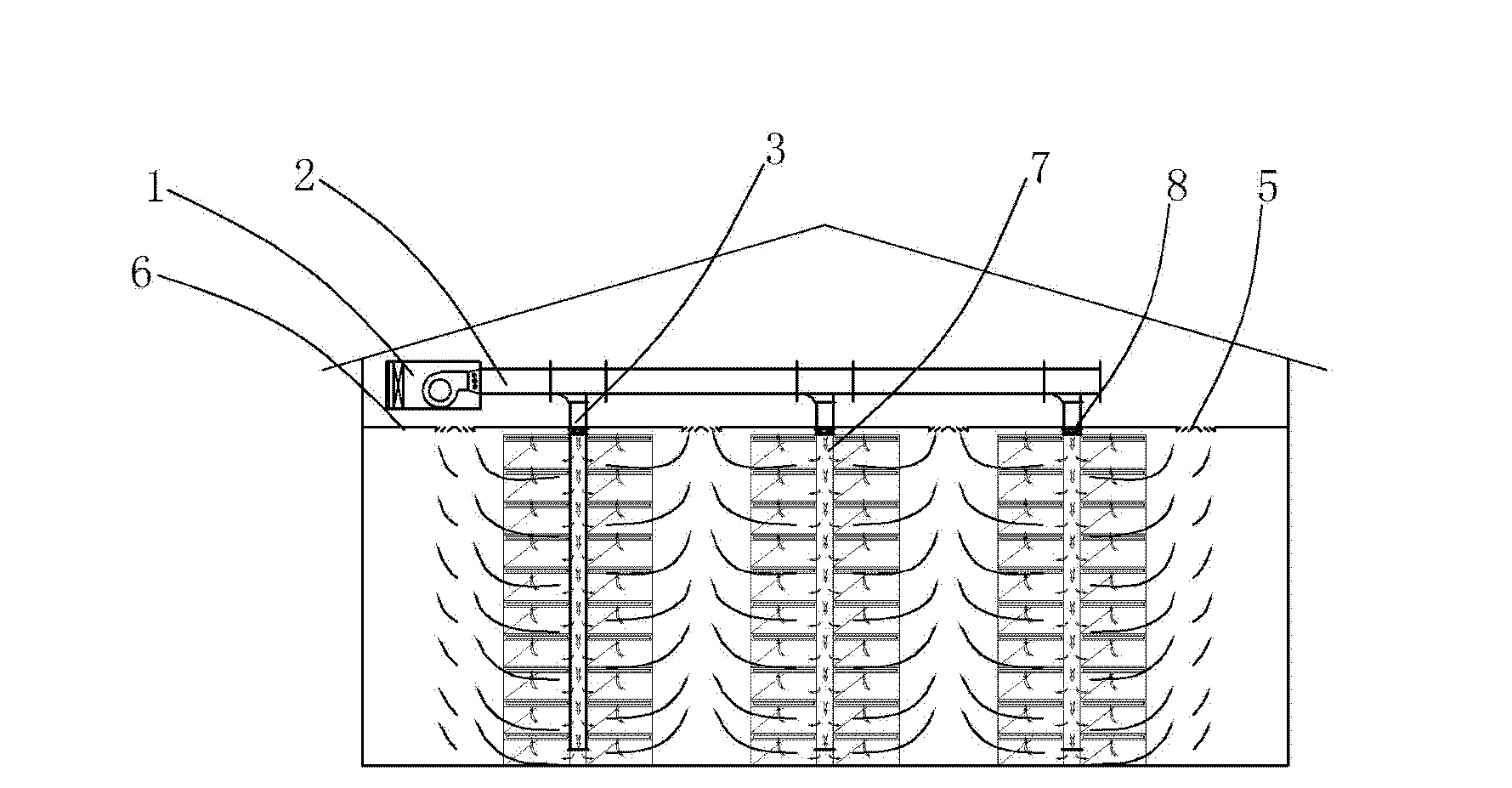

[0023] Example: see figure 2 , 3 , the plant factory of the present embodiment uses the air conditioner to send and return air system, including:

[0024] The air handling unit 1, the horizontal air supply main pipe 2 arranged above the ceiling 6 of the workshop and communicated with the air handling unit, each of the horizontal air supply main pipes is connected with a plurality of vertical air supply branch pipes 7, and each vertical air supply branch pipe The upper end communicates with the horizontal air supply main pipe 2 through the air volume regulating valve 8 and the transition air pipe 3 .

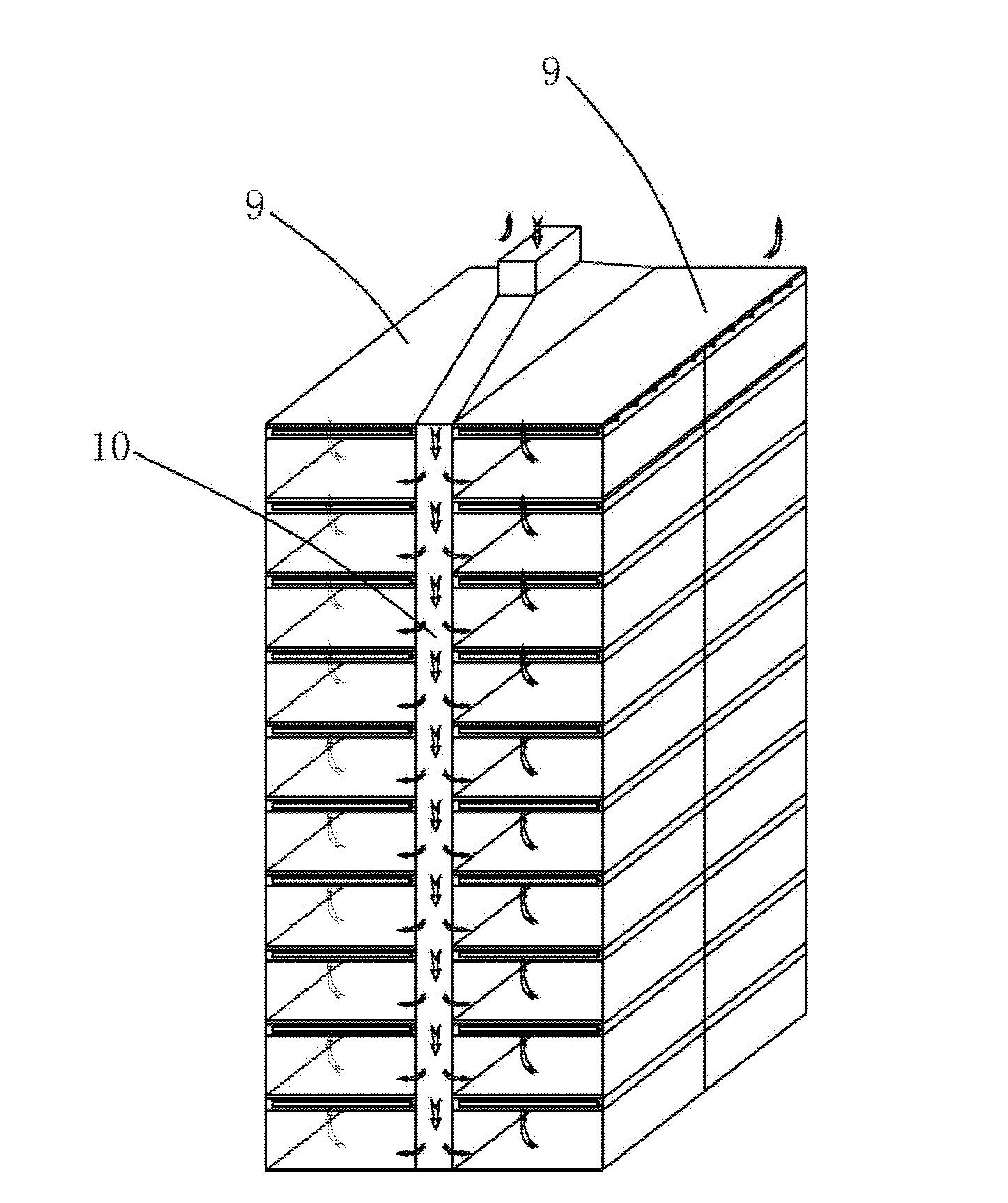

[0025] Below the ceiling 6 of the factory building, there are multiple rows and multi-layer plant cultivation frames 9, and a vertical air supply branch pipe 7 is arranged between every two rows of the plant cultivation frames 9. An independent single air-conditioning unit is formed, the vertical air supply branch pipe 7 supplies air from the side of the single air-conditionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com