Intensive plant factory with high light-energy utilization rate

A utilization-intensive technology, applied in botany equipment and methods, horticulture, greenhouse cultivation, etc., can solve the problem of no space utilization optimization design, etc., to achieve the goal of improving light energy utilization, uniform illumination, and saving aisle space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

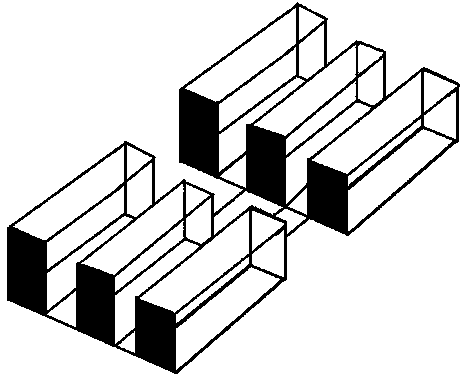

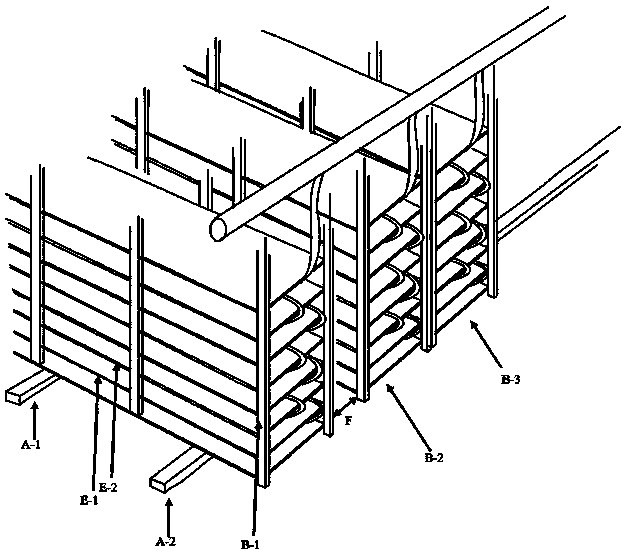

[0022] In this implementation plan, first of all, in order to reduce and optimize the proportion of non-productive area in the whole plant factory, a systematic planning and design is made for the passage and distribution between the cultivation racks of the previous plant factory. The design diagram is shown in figure 2 . The whole plant factory adopts the plant cultivation frame group as the carrier collection of the plant growth unit. Each production workshop in the plant factory is composed of a plant cultivation frame group, and the plant cultivation frame group is composed of multiple rows of horizontally elongated single cultivation frames. figure 2 Among them, B-1, B-2, and B-3 are all cultivation frames, and they jointly form a cultivation frame group. There are slidable tracks between the vertical cultivation frames, figure 2 Among them, A-1 and A-2 are slidable tracks, and the whole cultivation frame group is only provided with a unit width ( figure 2 Sliding...

Embodiment approach 2

[0025] In this implementation plan, first of all, in order to reduce and optimize the proportion of non-productive area in the whole plant factory, a systematic planning and design is made for the passage and distribution between the cultivation racks of the previous plant factory. The design diagram is shown in figure 2 . The whole plant factory adopts the plant cultivation frame group as the carrier collection of the plant growth unit. Each production workshop in the plant factory is composed of a plant cultivation frame group, and the plant cultivation frame group is composed of multiple rows of horizontally elongated single cultivation frames. figure 2 Among them, B-1, B-2, and B-3 are all cultivation frames, and they jointly form a cultivation frame group. There are slidable tracks between the vertical cultivation frames, figure 2 Among them, A-1 and A-2 are slidable tracks, and the whole cultivation frame group is only provided with a unit width ( figure 2 Sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com