Self-adaptive light supplementing system and method for plant factory

An adaptive and supplementary light technology, applied in the field of artificial light sources, can solve the problems of reducing light source uniformity, production environment pollution, and increasing the workload of staff, so as to reduce the probability of pollution, reduce labor intensity, and improve energy utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

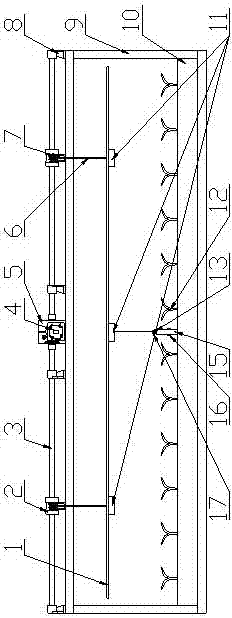

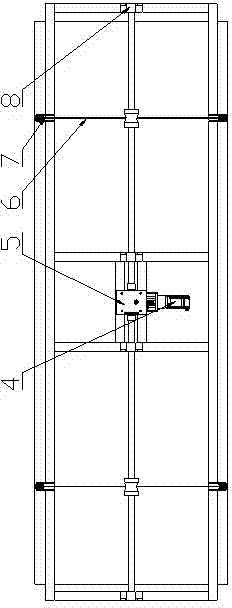

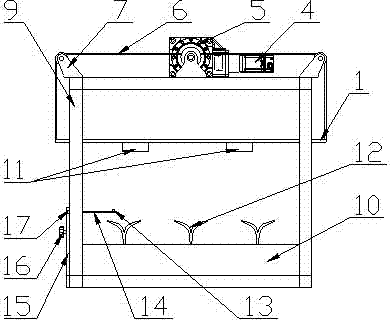

[0021] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] combine figure 1 , figure 2 and image 3 As shown, the executive module includes a supplementary light 1, a wire reel 2, a reel 3, a stepper motor 4, a worm gear transmission box 5, a steel rope 6, a pulley assembly 7, a bearing seat 8, a cultivation frame 9 and a cultivation bed 10 . The cultivation frame 9 is a unit body of the complete cultivation frame, and except the fill light 1, all other components are installed on the basis of the cultivation frame 9. Wherein the cultivation bed 10 is a soilless cultivation tank for planting plants 12, the bearing block 8 plays the role of supporting the winding shaft 3, and the pulley assembly 7 is used to change the direction of the wire rope 6. When the stepper motor 4 rotates, the motor main shaft drives the worm in the worm gear box 5 to rotate, and through a group of worm gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com