Device and method for regulating and controlling density of soilless cultured plants of plant factory

A technology of soilless cultivation and plant density, applied in the direction of soilless cultivation, botany equipment and methods, cultivation, etc., can solve the problems of lower production efficiency, difficulty in implementation, waste of light, etc., and achieve improved power utilization rate, compact and practical structure , the effect of reducing light waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a cultivation plate, at least two cultivation units

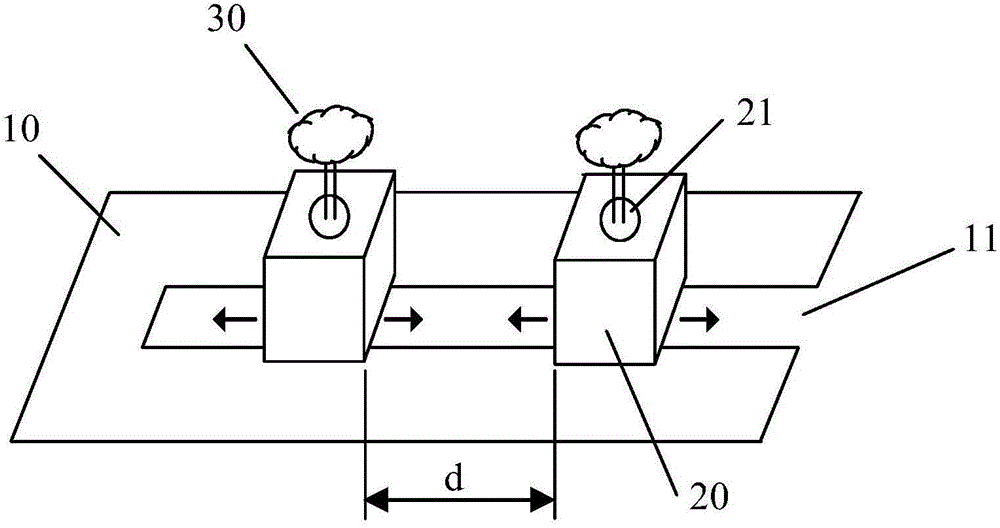

[0026] Such as figure 1 Shown, comprise cultivation board 10 and two or more cultivation units 20, cultivation board 10 is provided with strip opening 11, each cultivation unit 20 is erected on the strip opening 11, and can move along strip opening 11 ( The small arrow in the figure indicates the moving direction) to adjust the distance d. The cultivating unit 20 is provided with a cultivating hole 21 for accommodating the plant 30, and the cultivating unit 20 is provided with a sponge block for fixing the plant (plant).

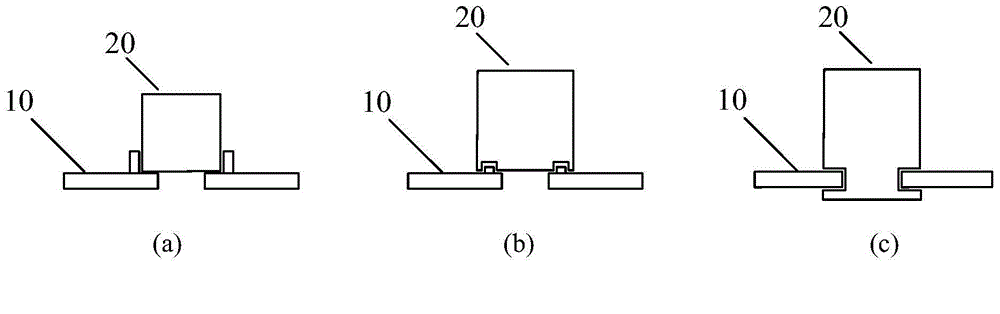

[0027] Among them, in order to make the combination of the cultivation unit 20 and the strip-shaped opening 11 relatively tight and firm, and to facilitate sliding, it is possible to increase the guide rail structure that cooperates with each other, such as figure 2 structure shown. Guide rails can be provided on the two edges of the strip-shaped opening 11, and the cultivation un...

Embodiment 2

[0028] Example 2: At least two growing plates

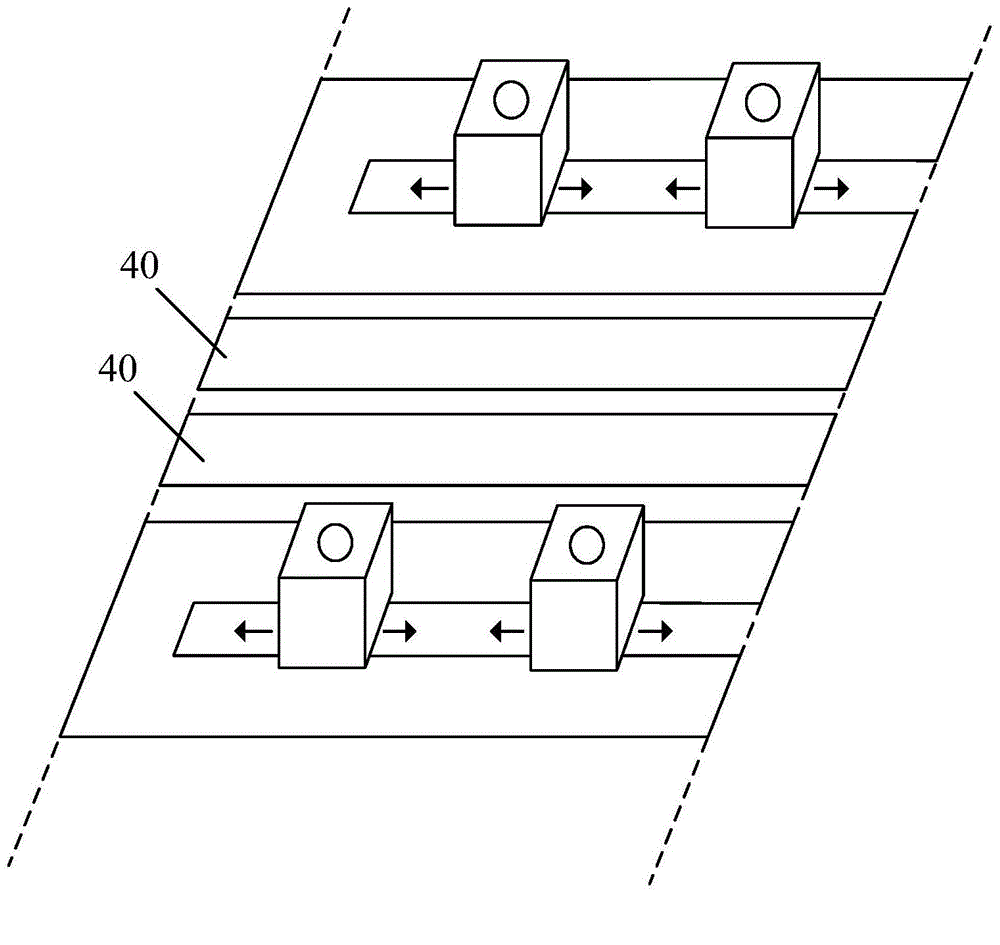

[0029] Such as image 3 As shown, there are at least two cultivation boards in this embodiment (two in the figure), and at least one additional cultivation board 40 for adjusting the distance between the cultivation boards is provided between the cultivation boards. During use, each cultivation unit moves along the strip-shaped opening of the cultivation board to adjust the plant spacing, and by adding or reducing additional cultivation boards, and correspondingly reducing or increasing the number of cultivation boards 10, to adjust the row spacing.

Embodiment 3

[0030] Example 3: A soilless cultivation device comprising a cultivation bed

[0031] Such as Figure 4 Shown is the soilless cultivation device with adjustable plant density of this embodiment, including a cultivation bed 50, the cultivation bed 50 is a square groove or a U-shaped groove, and its upper edge covers the cultivation board 10, The cultivation unit 20 and the additional cultivation board 40 . Covering the additional cultivation board 40 in the gap between the cultivation boards 10 can make the cultivation bed form a relatively airtight space and reduce the evaporation loss of the nutrient solution in the cultivation bed.

[0032] Such as Figure 4 As shown by the middle arrow, the cultivation board 10 can slide or move on the cultivation bed 50 in this embodiment, and the row spacing of plants can be adjusted by the movement of the cultivation board 10 . The movement of the cultivation board 10 in this embodiment can be used in conjunction with the additional c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com