Automatic three-dimensional layer frame type plant factory

A three-dimensional, shelf technology, applied in the field of automated three-dimensional shelf-type plant factories, can solve the problems of high labor intensity, low production efficiency, and low economic benefits for workers, and achieve improved operation safety, improved work efficiency, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

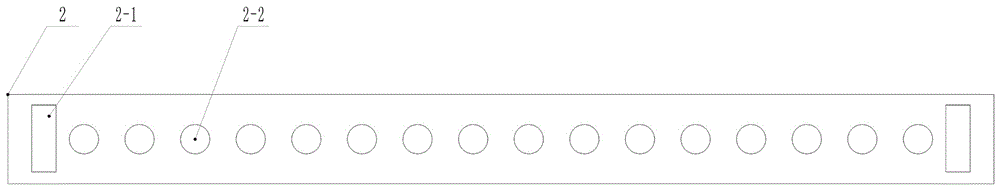

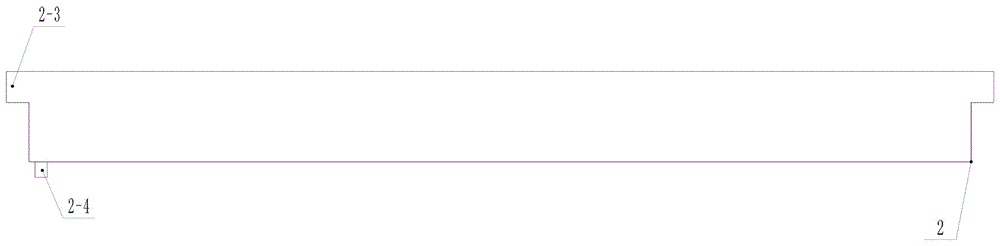

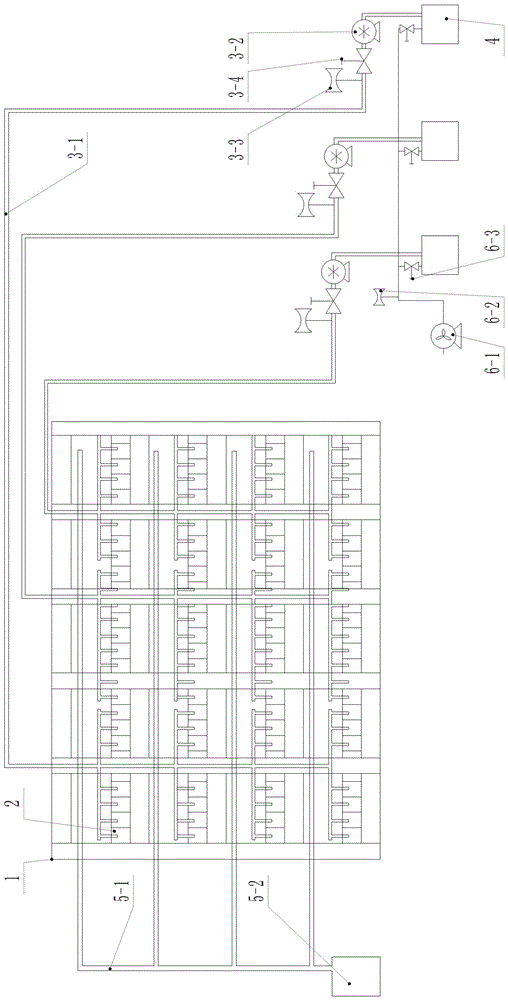

[0035] refer to Figure 1-1-Figure 2-2 , an automated three-dimensional shelf-type plant factory, comprising a three-dimensional shelf-type cultivation shelf 1, also comprising

[0036] Planting tank 2, which is movably arranged on the cultivation layer frame 1;

[0037] The three-dimensional tank frame transport device, the three-dimensional tank frame transport device includes a horizontal transmission mechanism that can drive the planting tank body 2 to move horizontally, and a longitudinal transmission mechanism that can drive the planting tank body 2 to move vertically;

[0038] The three-dimensional tank frame pipeline, the three-dimensional tank frame pipeline includes but not limited to the nutrient solution delivery pipeline 3-1, one end of the nutrient solution delivery pipeline 3-1 communicates with the planting tank body 2, and the other end is mixed with the nutrient solution Groove 4 is connected.

[0039] The three-dimensional shelf type cultivation shelf 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com