Plant factory

A plant and factory technology, applied in botany equipment and methods, soilless cultivation, cultivation, etc., can solve problems such as nutrient solution pollution, large energy consumption, and cumbersome maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

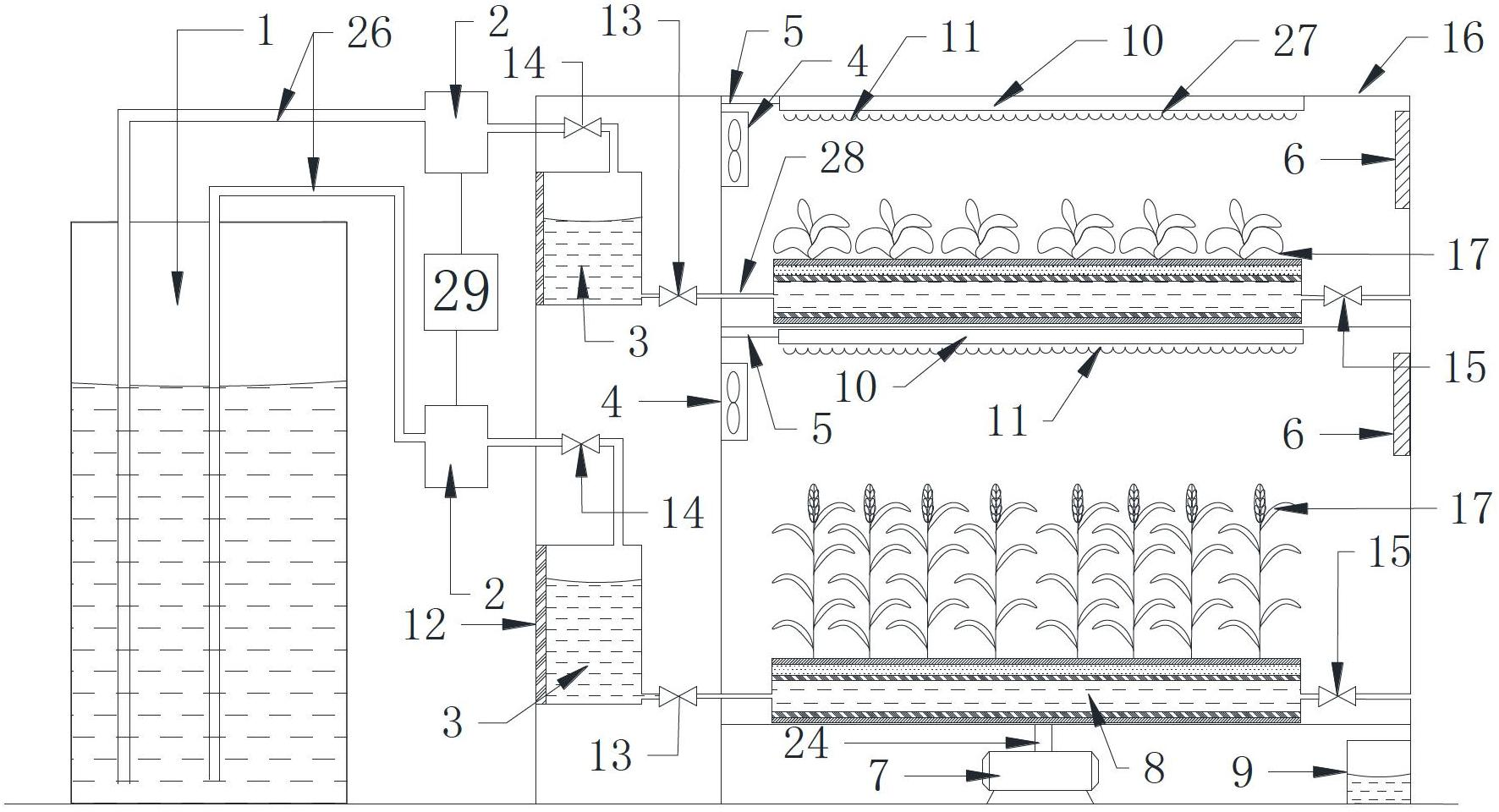

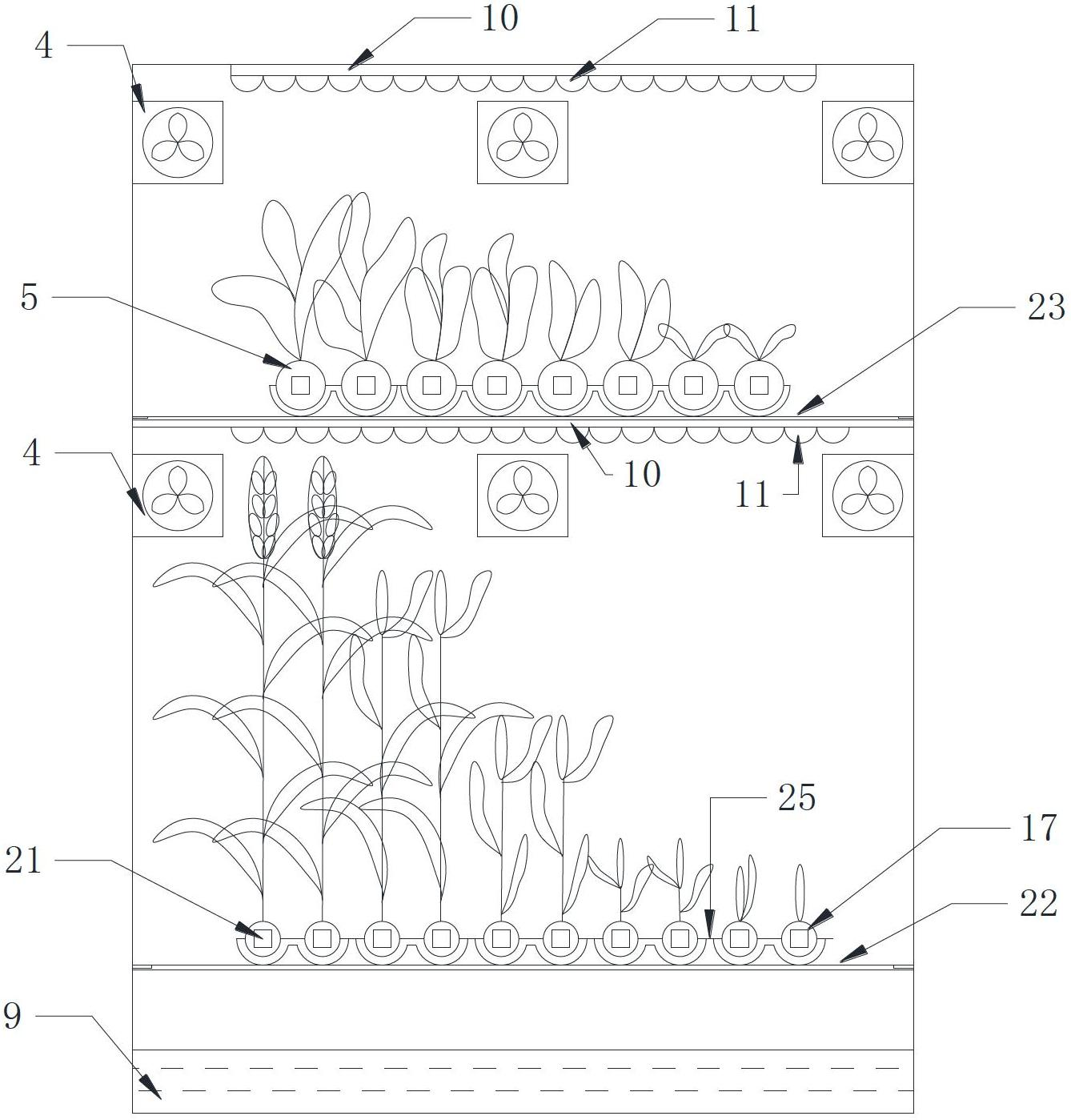

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the description.

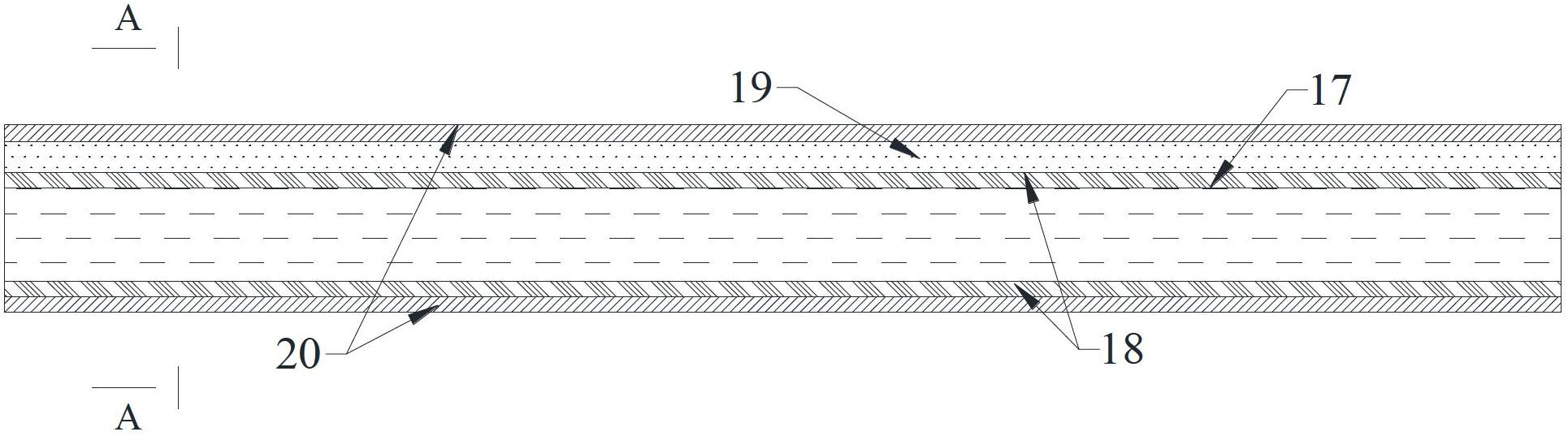

[0017] like figure 1 , figure 2 As shown, the device of the present invention is mainly composed of a variable-height plant cultivation unit 17 , an on-demand nutrient solution supply unit 26 , and an adjustable lighting unit 27 . First, adjust the height of the upper cultivation plate 22 and the lower cultivation plate 23 from the illumination unit 27 and the distance between the microporous tube modules 8 according to the plant height and planting density of the plant species. Then the two ends of the microporous tube module 8 are sealed with silica gel plugs 21 respectively, and the exterior tightly wraps the nylon microfiltration membrane 18, and the hydrophilic plant culture substrate strip 19 is placed on the top of the exterior, and the exterior is covered with a reflective waterproof evaporation film 20. After finishing, it is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com