Method for concentrating highly effective nitrobacteria in active sludge

A technology of activated sludge method and nitrifying bacteria, applied in chemical instruments and methods, bacteria, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

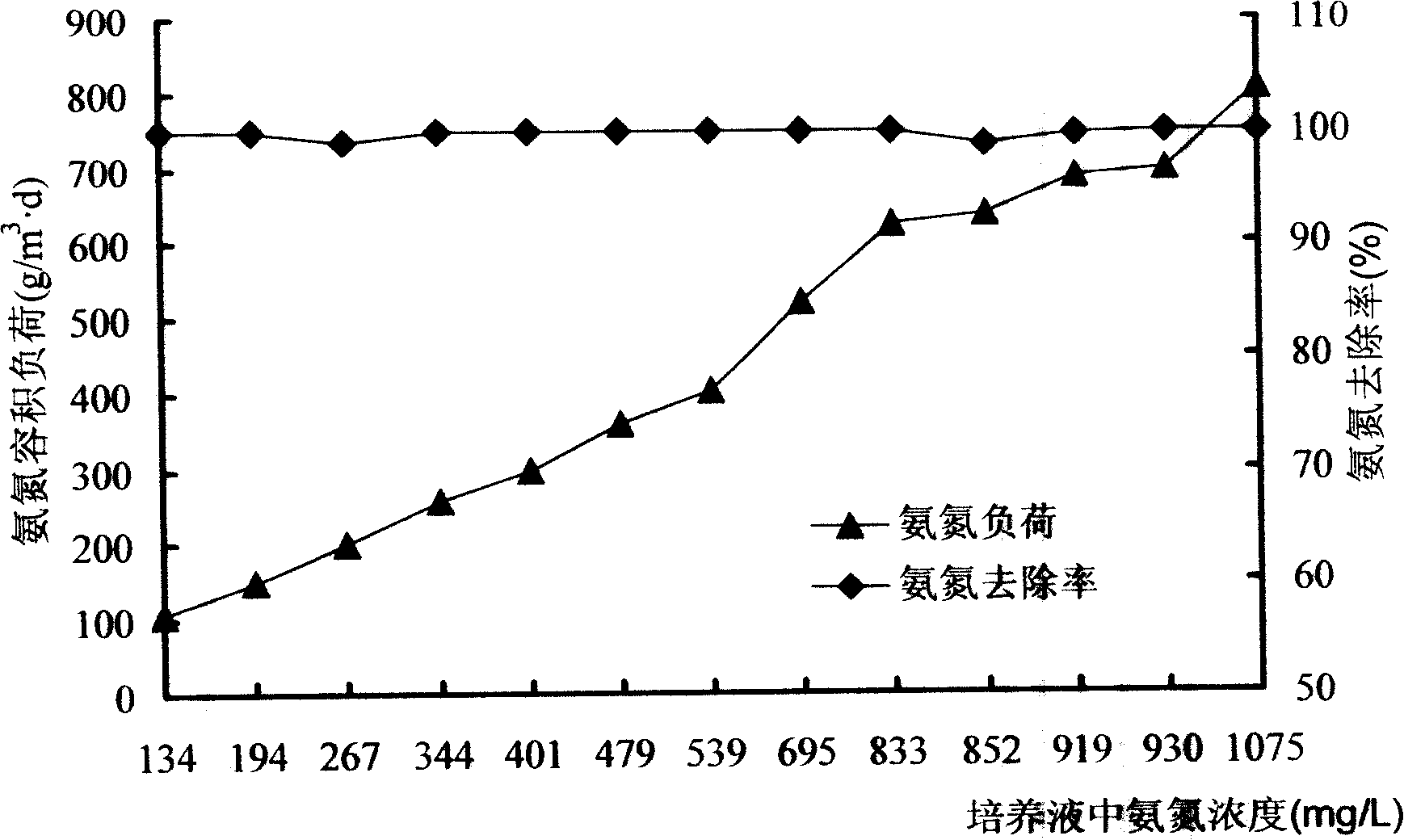

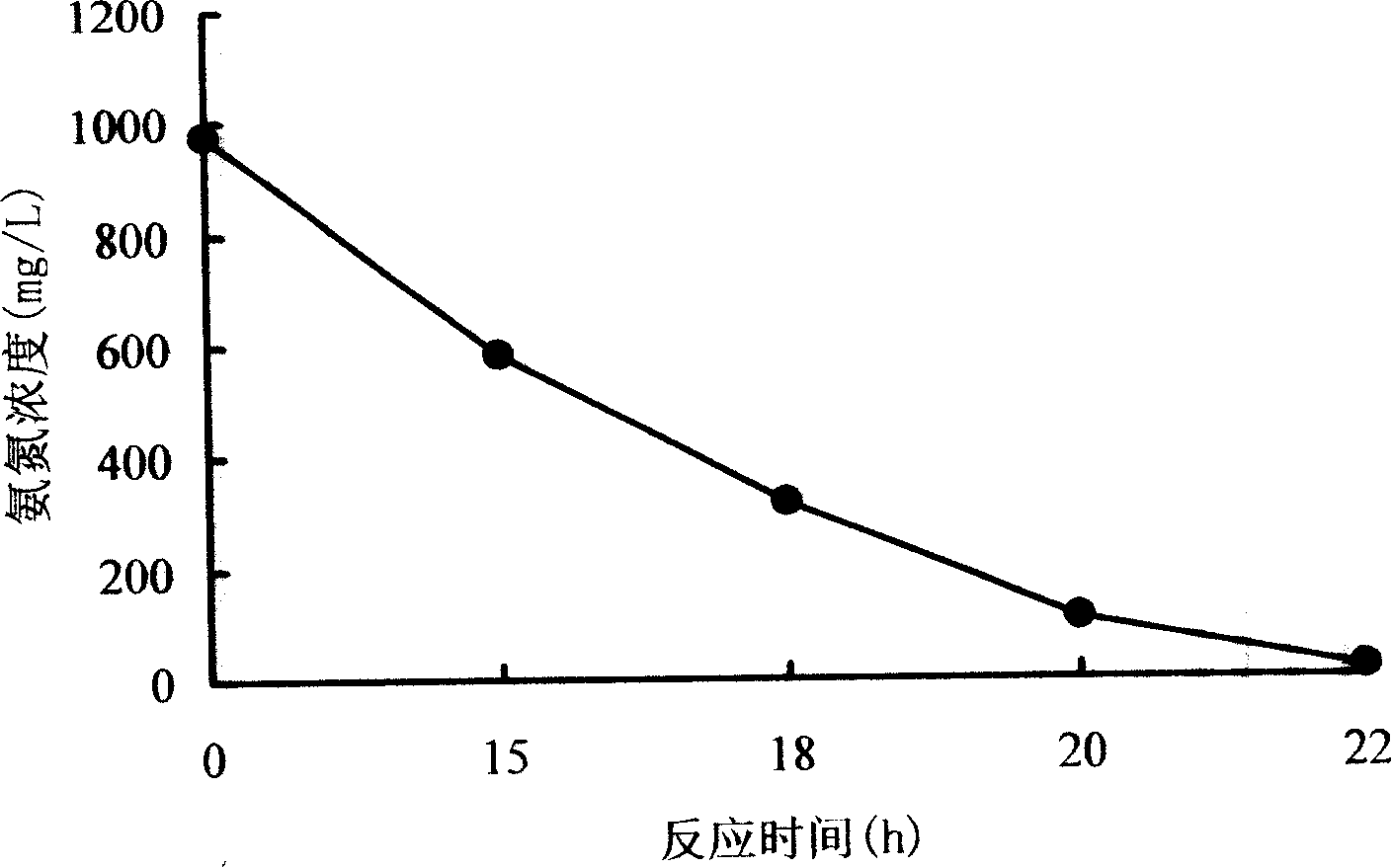

[0025] Nitrifying bacteria are enriched by intermittent activated sludge method. The activated sludge is taken from the outlet sludge of the secondary settling tank in the wastewater treatment workshop of the refinery, and inoculated into the enrichment reactor with an inoculation amount of 30v%, with a total volume of 3L , and then add the enrichment medium, wherein the composition of the enrichment medium used is (NH 4 ) 2 SO 4 , FeSO 4 ·7H 2 O, MgSO 4 ·7H 2 O, NaCl, CaCl 2 and KH 2 PO 4 , the concentration is as follows: NH 4+ -N initial concentration is 150mg / L, final concentration is 1000mg / L; Fe 2+ The concentration is 12mg / L; Mg 2+ The concentration is 18mg / L; Na + The concentration is 800mg / L; Ca 2+ The concentration is 16mg / L; KH 2 PO 4 The concentration is 260mg / L. During the enrichment process, NaHCO was used 3 Control pH. Culture conditions: temperature: 24°C; pH=6.0-7.5; SV: 15%-20%; DO: 10 mg·L -1 . One cycle per day, the water inlet time is 20...

Embodiment 2

[0028] The nitrifying bacteria were enriched by the batch activated sludge method. The activated sludge was taken from the sludge at the outlet of the secondary sedimentation tank in the wastewater treatment workshop of the refinery, and was inoculated into the enrichment reactor with an inoculation amount of 22v%, with a total volume of 3L. , and then add the enrichment medium, the composition of the enrichment medium used is the same as that of Example 1, but the concentration is different, as follows: NH 4 + -N initial concentration is 100mg / L, final concentration is 550mg / L; Fe 2+ The concentration is 6mg / L; Mg 2 + The concentration is 10mg / L; Na + The concentration is 300mg / L; Ca 2+ The concentration is 8mg / L; KH 2 PO 4 The concentration is 100mg / L. During the enrichment process, NaHCO was used 3 Control pH. The culture conditions are: temperature: 25°C; pH=6.0-7.5; SV: 15%-25%; DO: 5 mg·L -1 . 2 cycles per day, the water inlet time is 10 minutes, the aeration ...

Embodiment 3

[0031] The nitrifying bacteria were enriched by the batch activated sludge method. The activated sludge was taken from the outlet sludge of the catalyst wastewater treatment workshop, and was inoculated into the enrichment reactor with an inoculum of 28v%, with a total volume of 3L, and then the enrichment reactor was added. The enriched culture solution used is the same as Example 1, but the concentration is different, as follows: NH 4 + -N initial concentration is 180mg / L, final concentration is 800mg / L; Fe 2+ The concentration is 10mg / L; Mg 2+ The concentration is 12mg / L; Na + The concentration is 500mg / L; Ca 2+ The concentration is 10mg / L; KH 2 PO 4 The concentration is 200mg / L. During the enrichment process, NaHCO was used 3 Control pH. The culture conditions are: temperature: 28°C; pH=6.0-8.5; SV: 15%-20%; DO: 8 mg·L -1 . One cycle per day, the water inlet time is 30 minutes, the aeration time is 22.5 hours, the natural sedimentation is 40 minutes, and the supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume load | aaaaa | aaaaa |

| Volume load | aaaaa | aaaaa |

| Volume load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com