Preparation method of super-hydrophilic/underwater super-oleophobic filter paper

An underwater super-oleophobic and super-hydrophilic technology, which is applied in the direction of filter paper, separation methods, chemical instruments and methods, etc., can solve the problems of poor corrosion resistance, low separation efficiency of filter paper, poor recycling performance, etc. Weak force, good separation effect, excellent durability and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

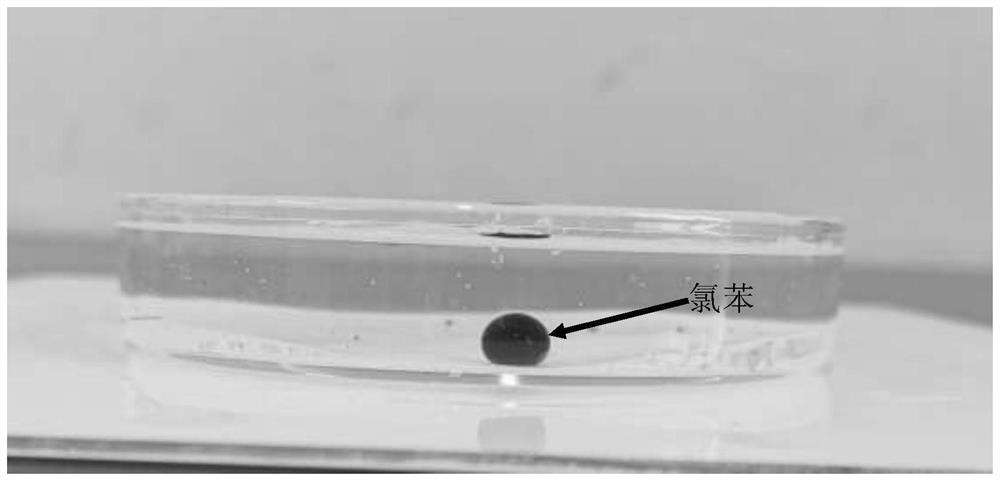

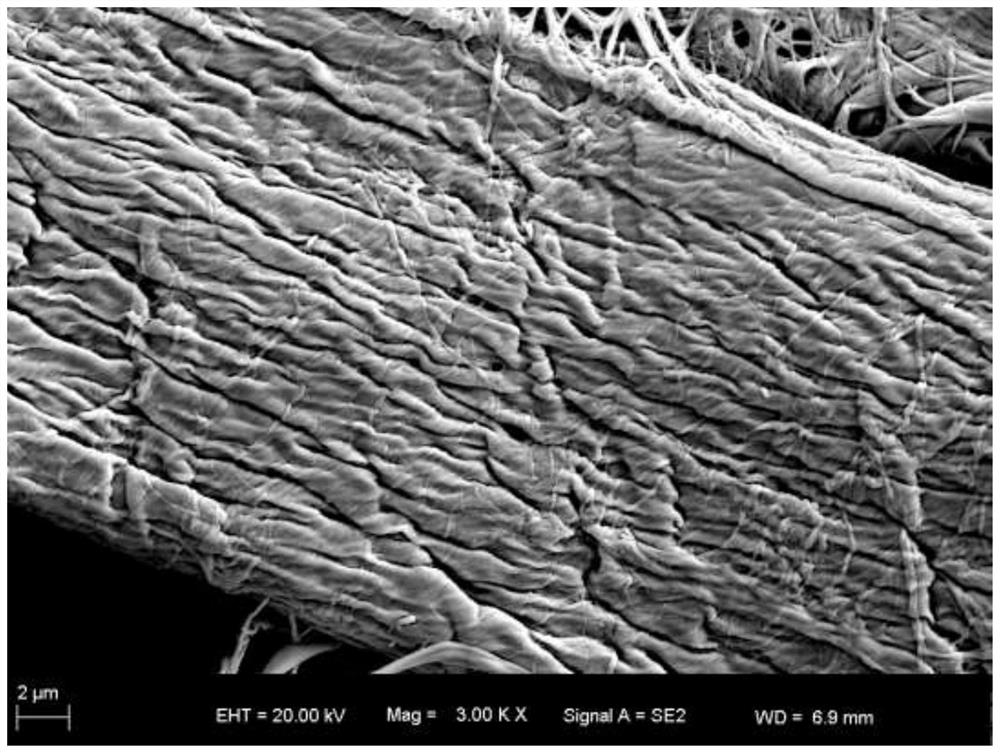

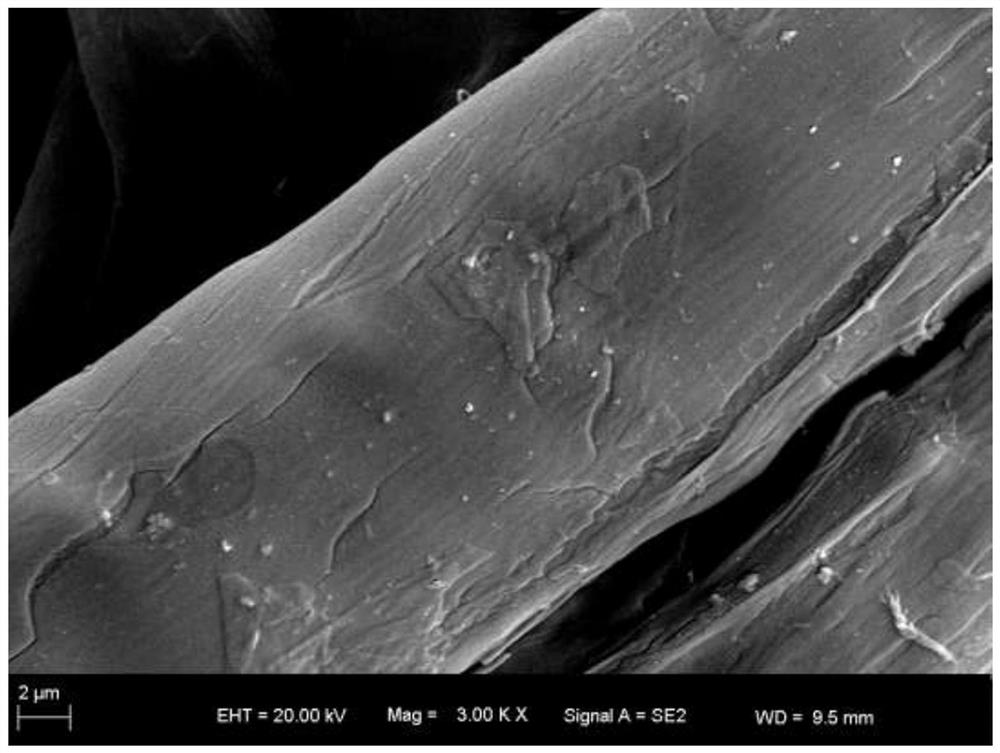

[0031] First, mix 0.41g of tetraethyl orthosilicate and 0.04g of acetylacetone and stir at room temperature for 1 hour, then add 0.216g of distilled water to the solution and dilute to 20ml with absolute ethanol, and continue to stir at room temperature for 4 hours , Add 0.01 g of nitric acid dropwise during stirring. After the stirring, the sol was allowed to stand and age for 12 hours to obtain 0.1 mol / L SiO 2 Sol, coated with a layer of SiO on the surface of filter paper by dip coating 2 gel, the immersion time is 1 min to ensure SiO 2 Complete infiltration of the sol on the filter paper fibers. After the filter paper was centrifuged at a speed of 500 rpm for 0.5 min, it was dried naturally at room temperature of 25°C. Put the filter paper on a heating platform at 80°C, and irradiate the surface of the filter paper with ultraviolet light with a wavelength of 257.3nm for 15 minutes to prepare the surface-deposited SiO 2 Functional filter paper with ceramic layer. figure...

Embodiment 2

[0033] First, mix 1.666g of tetraethyl orthosilicate and 0.16g of acetylacetone and stir at room temperature for 1.5 hours, then add 0.864g of distilled water to the solution and dilute to 20ml with absolute ethanol, and continue to stir at room temperature for 5 hours , drop 0.04g of nitric acid in the process of stirring. After stirring, the sol can be aged for 12 hours to obtain 0.4mol / L SiO 2 Sol. A layer of SiO was coated on the surface of filter paper by dip coating 2 Sol, the immersion time is 2 minutes. After the above treated filter paper was centrifuged at a speed of 1000 rpm for 1 minute, it was placed in an environment of 50° C. to dry. Put the filter paper on a heating platform at 100°C, and irradiate the surface of the filter paper with ultraviolet light with a wavelength of 257.3nm for 30 minutes to prepare the surface-deposited SiO 2Functional filter paper with ceramic layer. The static contact angle of functional filter paper surface to 1M HCl aqueous sol...

Embodiment 3

[0035] First, mix 2.499g of tetraethyl orthosilicate and 0.24g of acetylacetone and stir at room temperature for 2 hours. After stirring, add 1.296g of distilled water to the solution and dilute to 20ml with absolute ethanol, and continue to stir at room temperature for 6 Hour, in the process of stirring, drop the nitric acid of 0.06g. After stirring, the sol can be aged for 12 hours to obtain 0.6mol / L SiO 2 Sol, coated with a layer of SiO on the surface of filter paper by dip coating 2 Sol, the immersion time is 2 minutes. After the above treated filter paper was centrifuged at a speed of 1500 rpm for 1 minute, it was placed in an environment of 70° C. to dry. Place the filter paper on a heating platform at 120°C, and irradiate the surface of the filter paper with ultraviolet light with a wavelength of 257.3nm for 40 minutes to prepare the surface-deposited SiO 2 Functional filter paper with ceramic layer. The static contact angle of functional filter paper surface to 1M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com