Vanadium carbide gradient composite coating and preparation method thereof

A composite coating and vanadium carbide technology, which is applied in the coating, metal material coating process, etc., can solve the problems of thin reaction layer, strict control of type and content, and cracks in the cladding coating. The effect of simplicity, improved mechanical properties, and easy control of the thickness of the reaction layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

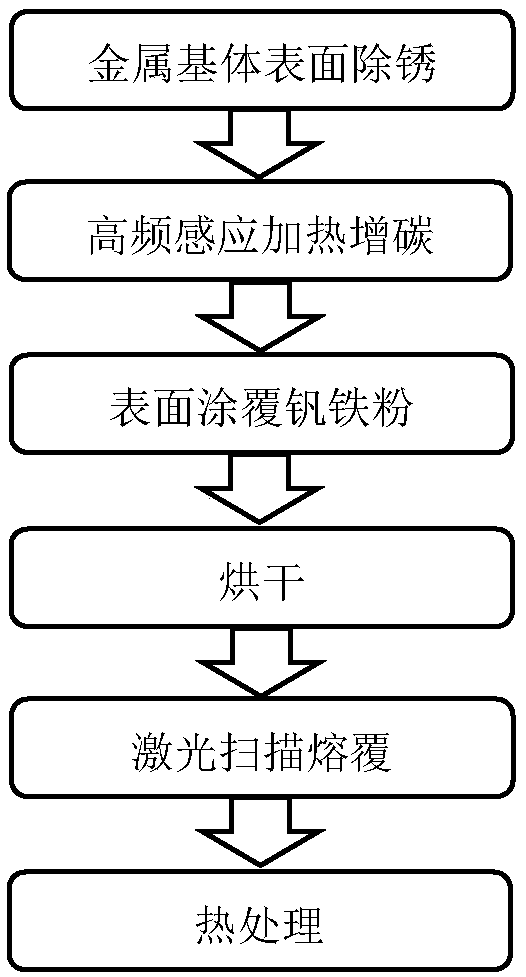

[0036] Such as figure 1 Shown, the preparation method of vanadium carbide gradient composite coating of the present invention comprises the steps:

[0037] 1) After pickling the surface of the metal substrate sequentially, select 800 mesh Al 2 o 3 Sanding, rust removal with sandpaper, and then ultrasonic cleaning with alcohol or acetone; metal substrate is low carbon steel 15 or 20 or low carbon alloy steel 15Cr, 20Cr, 20Mn2, 20MnV, 20CrMn, 20CrMnTi, 20MnTiB, 20MnVB, 18Cr2Ni4WA, 20Cr2Ni4 or 12Cr2Ni4 ; The metal matrix structure is one or more of pearlite, martensite, ferrite, bainite, austenite and sorbite according to the different heat treatment methods.

[0038] 2) Coat a layer of carburizer with a thickness of 0.2-1.0mm on the surface of the metal substrate after derusting and cleaning, adjust the carburizer to a fine paste with alcohol or acetone, and then coat it on low-carbon steel or low-carbon alloy Steel surface: graphite powder is used as recarburizer, the partic...

Embodiment 1

[0052] 1) First, carry out surface derusting (pickling) on the surface of 15 steel to be surface strengthened. The first step of pickling is to use 300ml / L hydrochloric acid, and then rinse with running water; the second step is to use 300ml / L hydrofluoric acid for pickling Acid, then rinse with running water; the third step is surface grinding, using 600 mesh Al 2 o 3 sandpaper, and finally ultrasonically cleaned with alcohol;

[0053] 2) Coating a layer of graphite powder with a particle size of 600 mesh and a purity of 85% on the surface of 15 steel, and adjusting it to a thin paste with alcohol;

[0054] 3) Apply the recarburizing agent on the surface of 15 steel with a thickness of 0.5mm; and then coat a layer of insulation layer on it, wherein the thickness of the insulation coating is 1mm; the composition of the insulation coating is: nonahydrate silicic acid Sodium 10%, Deionized Water 40%, Nano SiO 2 2%, hollow ceramic microspheres 25%, aluminum silicate fibers 3...

Embodiment 2

[0063] 1) First, carry out surface derusting (pickling) on the 20CrMn to be surface strengthened. The first step of pickling is to use 300ml / L hydrochloric acid, and then rinse with running water; the second step is to use 300ml / L hydrofluoric acid for pickling , and then washed with running water; the third step is surface grinding, using 600 mesh Al 2 o 3 sandpaper, and finally ultrasonically cleaned with alcohol;

[0064] 2) then coating a layer of graphite powder with a particle size of 700 mesh and a purity of 90% on the surface of 20CrMn, and adjusting it to a thin paste with acetone;

[0065] 3) Apply a layer of thermal insulation coating on it again, the thickness of the carburizing layer is 0.8mm; wherein, the thickness of the thermal insulation coating is 1.5mm;

[0066] Its thermal insulation coating composition is: sodium silicate nine hydrate 10%, deionized water 30%, nano-SiO 2 4%, hollow ceramic microspheres 20%, aluminum silicate fibers 9%, SiO 2 Airgel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com