Aluminum alloy/aluminum alloy-ceramic combined automobile brake disc and preparation method thereof

A technology of aluminum alloy and brake disc, which is applied in the direction of brake disc, brake type, brake components, etc. The aluminum alloy matrix has low bonding strength, and the ceramic particles are difficult to disperse uniformly, so as to achieve the effect of reliable operation, consistent heat treatment process, and improved bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method of preparing a car brake disc of a carbon alloy / aluminum alloy-ceramic combination of the present invention includes the following preparation steps:

[0037] (1) Aluminum, silicon, copper, magnesium, zinc, manganese, chromium, nickel, zinc, manganese, chromium, nickel, zinc, manganese, chromium, nickel, and zirconium, and the aluminum alloy powder is obtained after melting, refining, aerosol.

[0038] Among them, the melting temperature is 680 to 750 ° C, the resulting aluminum alloy powder particle size is -100. (2) The aluminum alloy powder obtained from which to (1) obtained by pressing the step (1) is mixed with the composite powder. Among them, the ceramic ball is used as the ball mill when mixed, and the ball milling time is 2 to 6 hours, which is a vacuum and closed environment.

[0039] (3) Put the composite powder obtained by step (2) into the aluminum alloy package, and then perform a hot vacuum except for the vacuum powder package.

[0040] (4) The va...

Embodiment 1

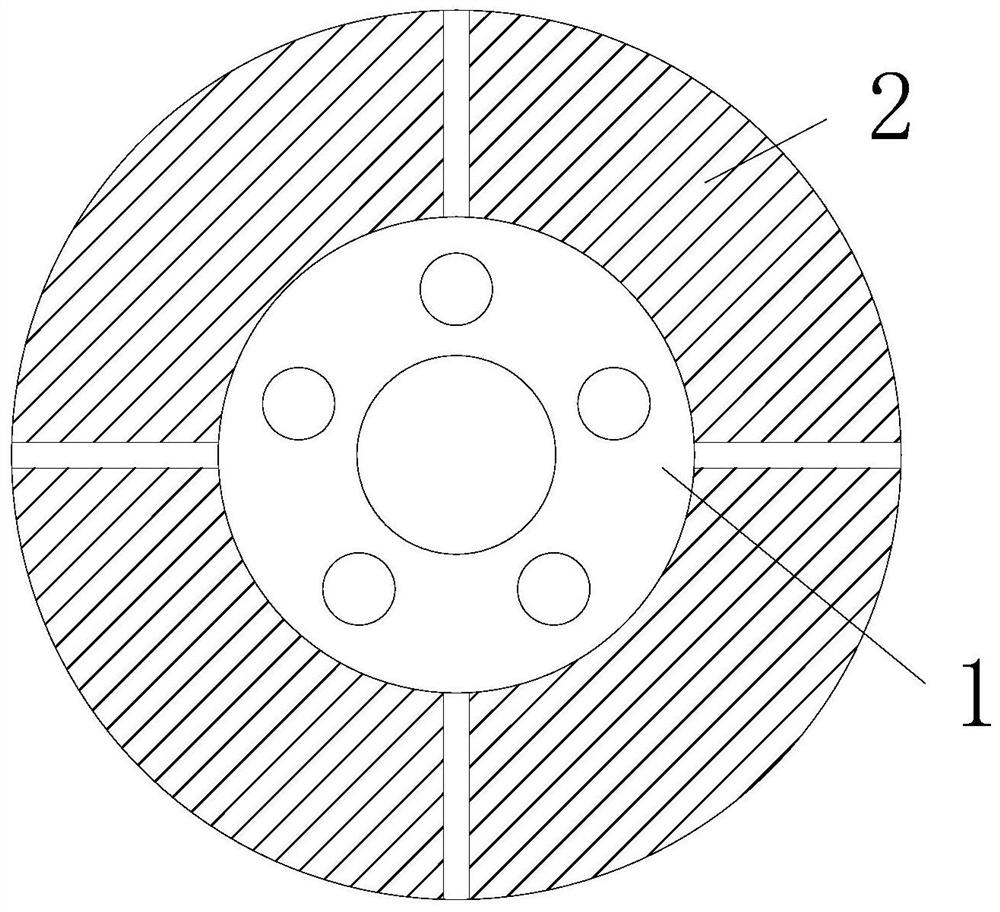

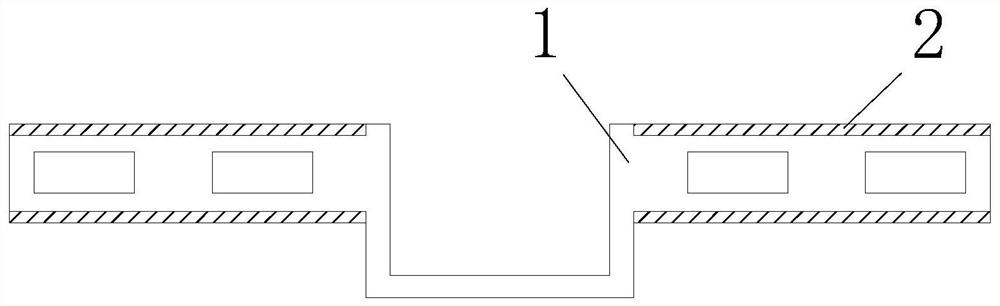

[0046] Refer figure 1 and 2 As shown, a vehicle brake disc of a combination of an aluminum alloy / aluminum alloy-ceramic combination of the present invention includes a brake surface of the brake disc main body 1, a wear-resistant layer 2, a brake disc main body 1 For the aluminum alloy matrix material, the abrasion layer 2 consists of the following percentage material: an aluminum alloy substrate 80%, ceramic phase 20%.

[0047] Wherein, the aluminum alloy matrix consists of 91.7% aluminum, 6.5% silicon, 0.25% of magnesium, 0.3% zinc, 0.35% manganese, 0.1% chromium, nickel, 0.2% Zirconium 0.25%.

[0048] The ceramic phase consists of the following percentage of materials: the potassium hexopeptidate is 20%, 30% silicon carbide fibers, and 50% of silicon carbide ceramic particles. The diameter of the hexapeptotassium potassium peripoperate is less than 50 nanometers, and the diameter of the silicon carbide fibers is 500 nm and the diameter of the silicon carbide is 1:50, and the ...

Embodiment 2

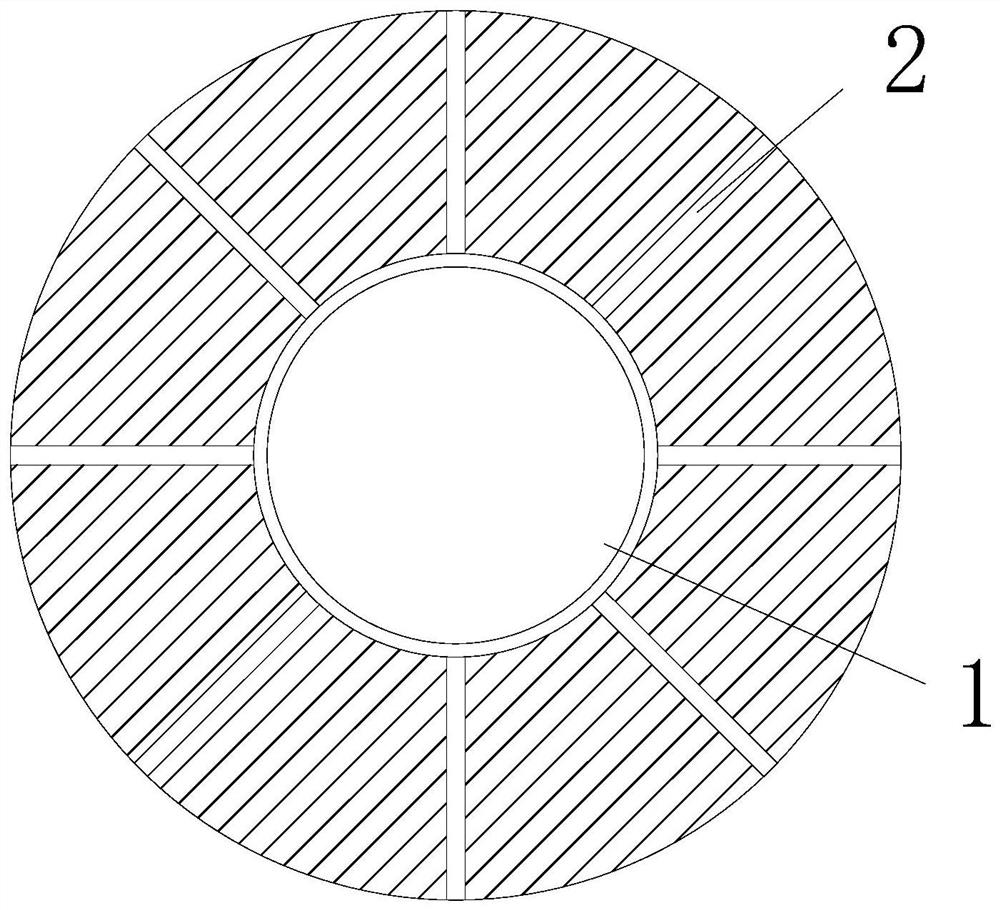

[0061] Refer image 3 and 4 As shown, a vehicle brake disc of a combination of an aluminum alloy / aluminum alloy-ceramic combination of the present invention includes a brake surface of the brake disc main body 1, a wear-resistant layer 2, a brake disc main body 1 For the aluminum alloy matrix material, the abrasion layer 2 consists of the following percentage material: an aluminum alloy substrate 80%, ceramic phase 20%.

[0062] Wherein, the aluminum alloy matrix consists of 89.75% aluminum, 0.1% silicon, 1.4% magnesium 1.5%, zinc 6.5%, manganese 0.1%, chromium 0.1%, nickel 0.1%, 0.2% Zirconium 0.25%.

[0063] The ceramic phase consists of the following percentage of material: the potassium titanate is 10%, 20% silicon carbide fibers, and 70% of silicon carbide ceramic particles. The diameter of the hexapeptotassium potassium peripoperate is less than 50 nanometers, and the diameter of the silicon carbide fibers is 500 nm and the diameter of the silicon carbide is 1:50, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com