Method for synthesizing copper-zinc-tin-sulfur nano-sheet array by two-step method

A nanosheet array, copper-zinc-tin-sulfur technology, applied in the field of nanomaterials, can solve the problems of complex process, difficulty in controlling the deposition thickness, and increase of vulcanization steps, so as to simplify the process, improve repeatability, and increase adjustability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

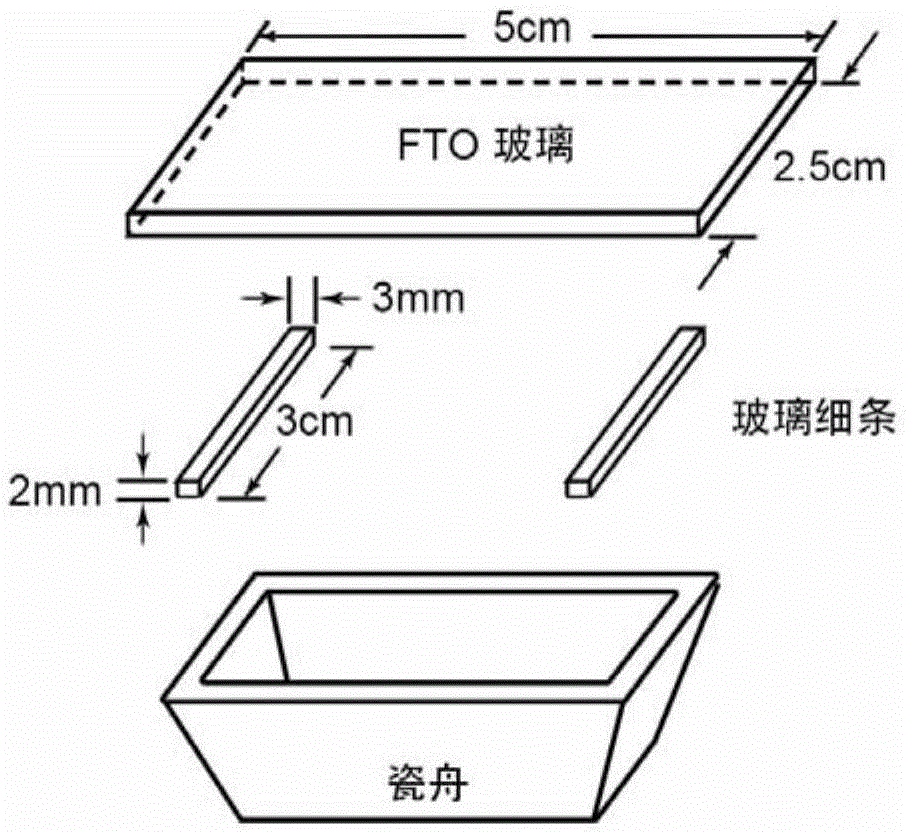

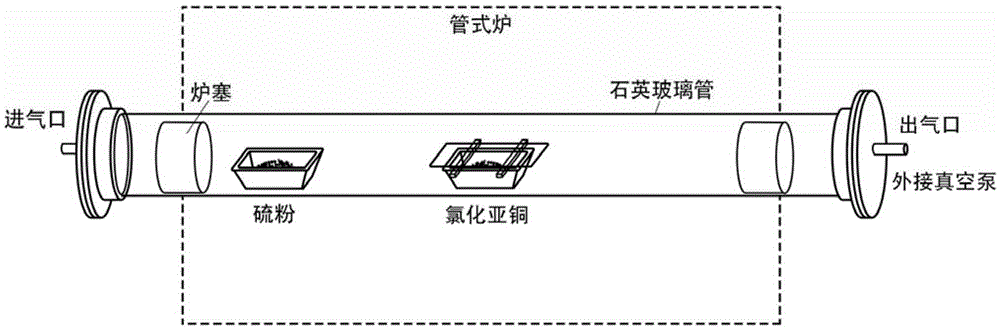

[0026] Such as figure 1 , figure 2 As shown, the FTO glass is cut into a size of 5cm×2.5cm (determined by the size of the porcelain boat and the size of the inner tank of the reactor, so as to ensure that it can be placed in the inner tank of the reactor without affecting the reaction), and between it and the ceramic boat Two thin and narrow glass strips are placed on the pad, and the length * width * height of the thin and narrow glass strips is 30mm * 3mm * 2mm.

[0027] The FTO glass must be cleaned in advance, first with washing powder for preliminary cleaning, then rinsed with deionized water and then placed in deionized water for 10 minutes of ultrasonication.

[0028] The size of the FTO glass and whether there is a gap between it and the porcelain boat are the key factors. In order to allow sulfur vapor to easily enter the porcelain boat and react with the difficult-to-diffuse cuprous chloride vapor, the substrate cannot completely cover the porcelain boat. , so a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com