A kind of bionic antifouling paint and its preparation method and application

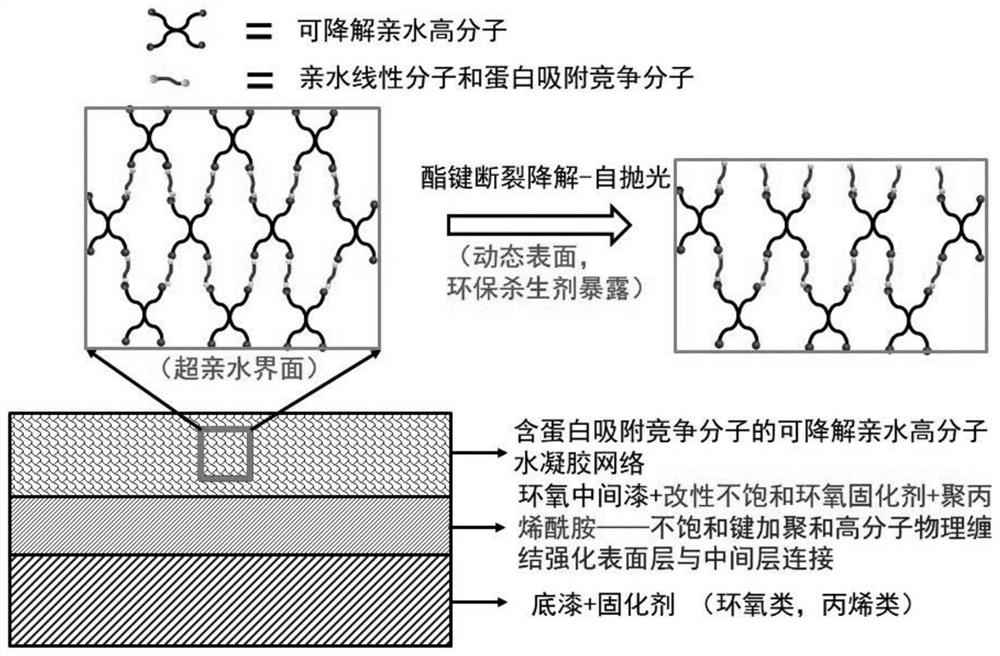

A technology of antifouling coatings and antifouling coatings, applied in the direction of antifouling/underwater coatings, polyether coatings, epoxy resin coatings, etc., can solve the problems of particularly huge marine environmental pollution and high environmental hazards of coatings, and achieve Long-term stability, good antifouling effect, and high interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of a novel bionic antifouling paint, the steps are as follows:

[0037]S1. Preparation of modified curing agent: Dissolve 10ml of triethyltetramine and 7ml of trimethylamine in 150ml of anhydrous dichloromethane, slowly add 6.3mL of acryloyl chloride in an ice bath, control the addition time for 30min, stir overnight at room temperature, The reaction mixture was then evaporated with a rotary evaporator to remove dichloromethane; the obtained residue was dissolved in 100ml, 100mM, pH=9.0 sodium bicarbonate solution, DMSO 100ml was added to the solution, shaken, and the modified The solidified product is extracted from the aqueous phase to the organic phase; then the organic liquid is separated with a separating funnel, and the extraction is repeated 5 times; then all the collected organic liquid is evaporated with a rotary evaporator to obtain triethylenetetramine containing unsaturated bonds ; The obtained triethylenetetramine, acrylamide, and uroca...

Embodiment 1

[0045] Example 1 The present invention is tested in terms of mechanical strength.

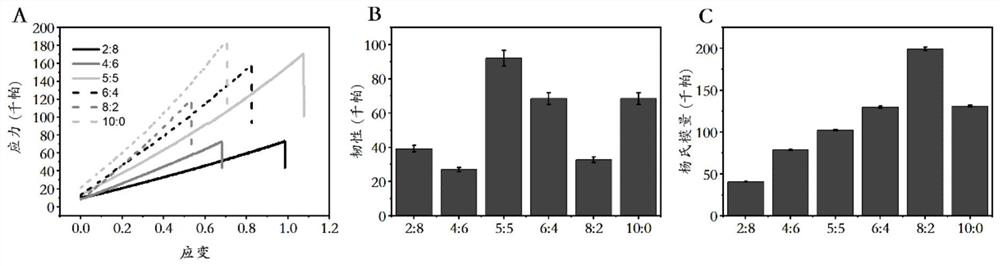

[0046] In terms of mechanical strength, we used a biomechanical testing machine to carry out tensile tests on the mechanical strength of the biomimetic anti-sewage gel in this design, and adjusted the mass ratio of acrylamide and polyethylene glycol in the hydrogel. The mechanical strength is optimized. Such as figure 2 As shown, the mass ratio of polyethylene glycol and acrylamide is set to 2:8, 4:6, 5:5, 6:4, 8:2, and the mass ratio of methacryloxypropyltrimethoxysilane remains as 0-5% of the sum of the mass of multi-arm polyethylene glycol and acrylamide. Depend on figure 2 A and B can find that when the mass ratio of polyethylene glycol and acrylamide is 5:5, the hydrogel exhibits the highest toughness, up to 92kJ m -3 , in tensile experiments, these results indicate that the designed biomimetic anti-fouling gel possesses ultra-high mechanical strength. Furthermore, the maximum break...

Embodiment 2

[0047] Example 2 The present invention is tested on the uniformity of micromechanical properties.

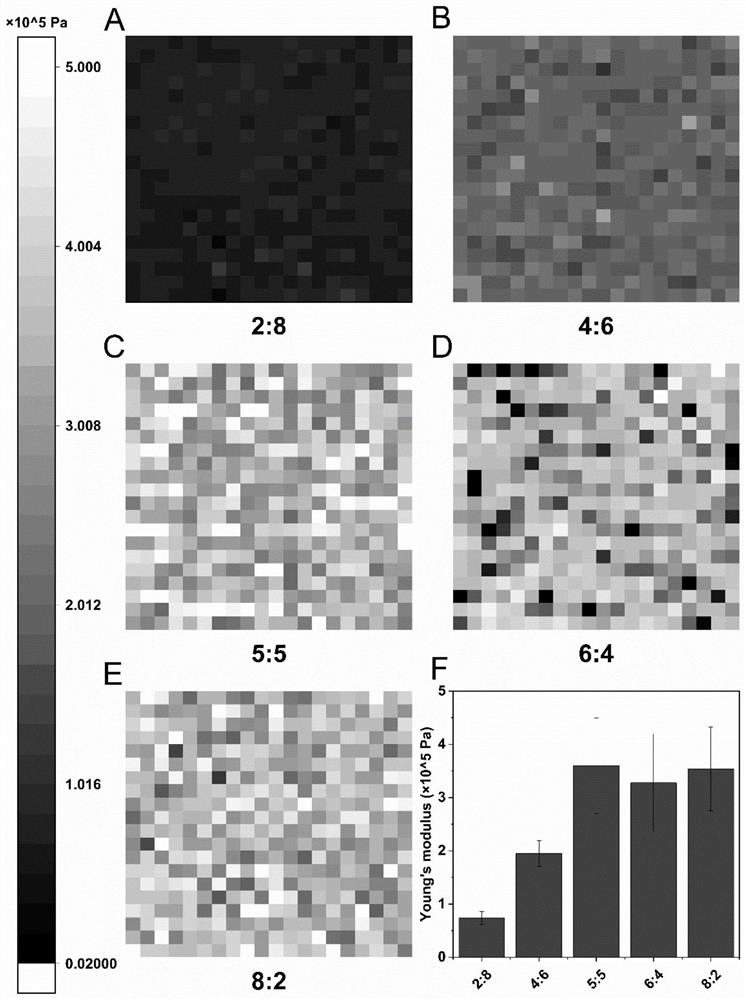

[0048] In terms of the uniformity of the micro-mechanical properties of the hydrogel, we used an atomic force microscope to measure and characterize the micro-domain mechanical properties of the hydrogel. The needle tip of the atomic force microscope kept approaching and moving away from the sample surface within the selected micro-domain. , detect the force signal in the process of approaching, and then calculate the Young’s modulus of each point according to the Hertz model, and draw it into a two-dimensional distribution map of the modulus of the hydrogel microdomain, as shown in image 3 shown. It can be found that under different mass ratios of polyethylene glycol and acrylamide, the distribution of Young's modulus of all hydrogels is relatively uniform, and the half-peak width of the modulus distribution is relatively small, indicating that this kind of hydrogel has relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com