Preparation method for self-polishing antifouling resin

An antifouling resin and self-polishing technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problem that the cyclic ester monomer is expensive, restricts the industrial production of self-polishing antifouling coatings, Single type and other problems, to achieve the effect of long-term antifouling, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

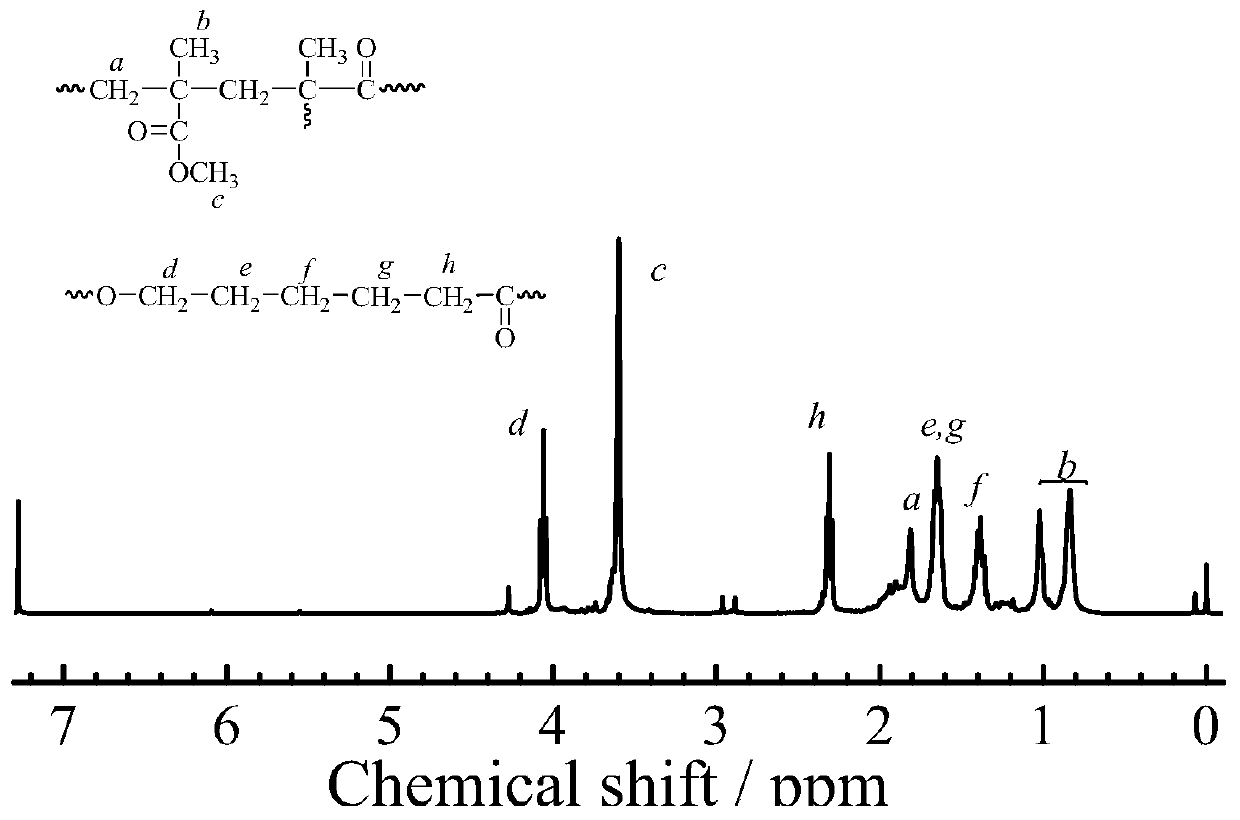

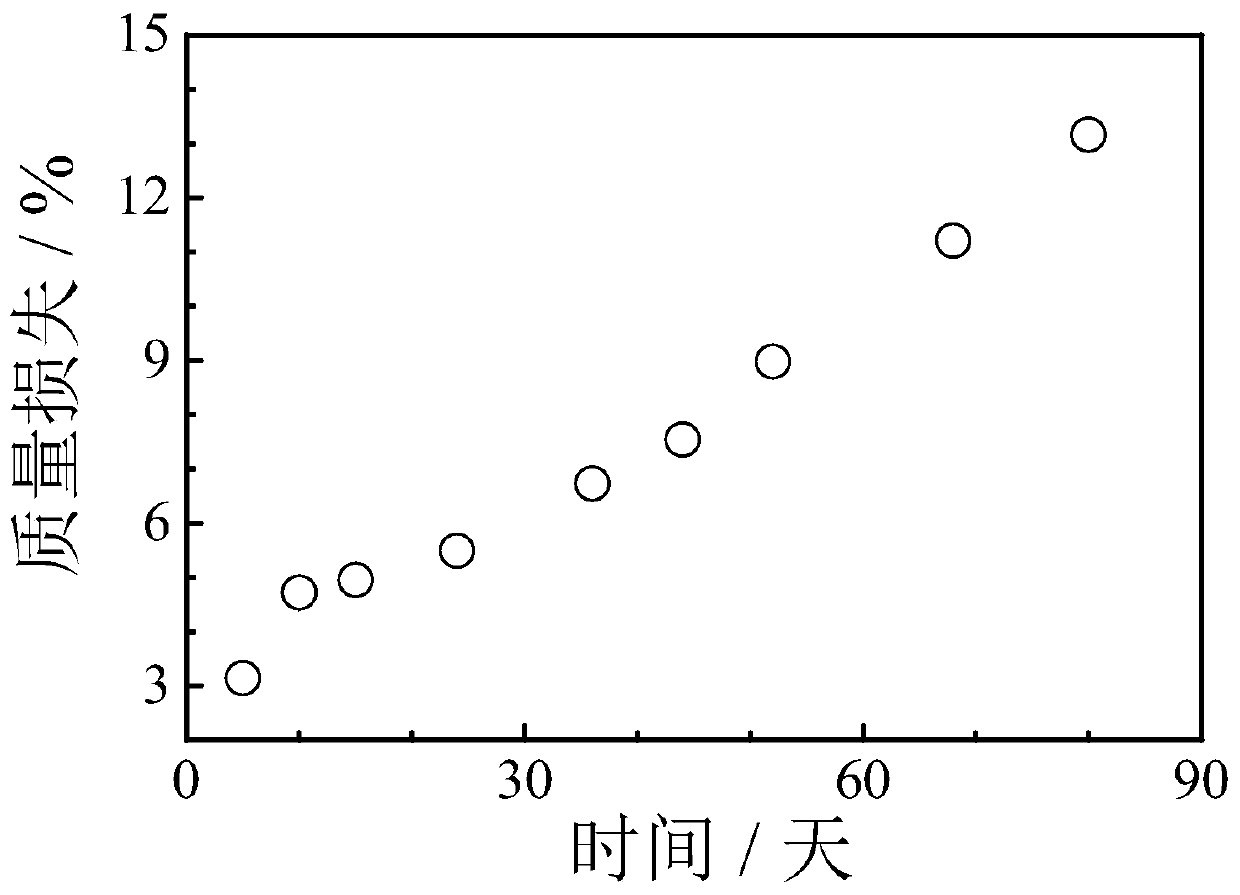

Method used

Image

Examples

Embodiment 1

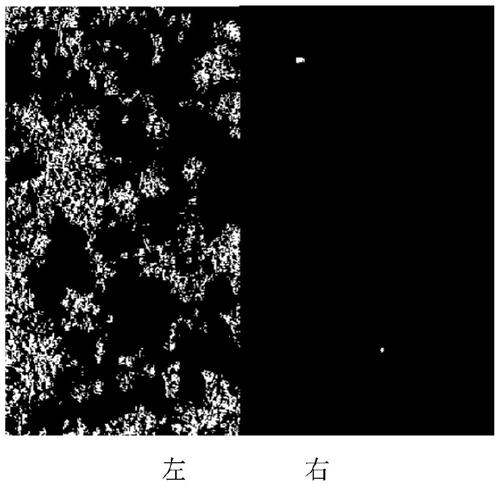

[0028] Get 11.41g ethyl methacrylate, 2.60g molecular weight is the polycaprolactone oligomer of the terminal double bond of 2600g / mol, 0.27g α-ethyl chloropropionate, 0.14g cuprous bromide and 0.31g bipyridine Place in a stirred 150mL round-bottomed flask, then add 14.01g of diethylene glycol dimethyl ether as a solvent, freeze with liquid nitrogen, replace argon three times, and then place it at 60°C for 24 hours. After the reaction, the reaction product was dissolved in tetrahydrofuran and then precipitated in 1000 mL of anhydrous methanol to obtain a resin for self-polishing antifouling coatings. The polymer weight average molecular weight is 4.02×10 5 g / mol, the molecular weight distribution is 5.73. The resin was coated on the steel plate pre-coated with anti-corrosion primer, and the shallow sea hanging plate test showed that no marine organisms grew on the surface within 8 months.

Embodiment 2

[0030] Get 10.01g methyl methacrylate, 5.00g molecular weight is the polyglycolide oligomer of the terminal double bond of 500g / mol, 1.95g α-bromo ethyl isobutyrate, 1.08g ferrous bromide and 1.56g bismuth Dipyridine was placed in a stirred 100mL round-bottomed flask, then 15.01g of tetrahydrofuran was added as a solvent, frozen in liquid nitrogen, replaced with argon three times, and placed at 40°C for 24h. After the reaction, the reaction product was dissolved in tetrahydrofuran and then precipitated in 500 mL of anhydrous methanol to obtain a resin for self-polishing antifouling coatings. The polymer weight average molecular weight is 1.28×10 5 g / mol, the molecular weight distribution is 8.33. The resin was coated on the steel plate pre-coated with anti-corrosion primer, and the shallow sea hanging plate test showed that no marine organisms grew on the surface within 8 months.

Embodiment 3

[0032] Get 8.61g methyl acrylate, 3.80g molecular weight is the poly(lactide-caprolactone) oligomer of terminal double bond of 3800g / mol, 0.50g molecular weight is the polyethylene glycol methyl acrylate of 500g / mol, 0.76 g methyl-2-(dodecyltrithiocarbonate)-2-methylpropionate, 0.17g azobisisobutyronitrile was placed in a stirred 150mL round bottom flask, then added 12.41g Toluene was used as a solvent, frozen in liquid nitrogen, replaced by argon three times, and reacted at 80°C for 24 hours. After the reaction, the reaction product was dissolved in tetrahydrofuran and then precipitated in 1000 mL of anhydrous methanol to obtain a resin for self-polishing antifouling coatings. The polymer weight average molecular weight is 4.89×10 5 g / mol, the molecular weight distribution is 6.91. The resin is coated on the steel plate pre-coated with anti-corrosion primer, and the shallow sea hanging plate test shows that no marine organisms grow on the surface within 10 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com