Plastic-film water intaglio printing ink

A gravure printing ink and plastic film technology, applied in printing, ink, printing device and other directions, can solve the problems of insufficient adhesion, slow drying speed, low gloss, etc., to improve adhesion fastness, good printability, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

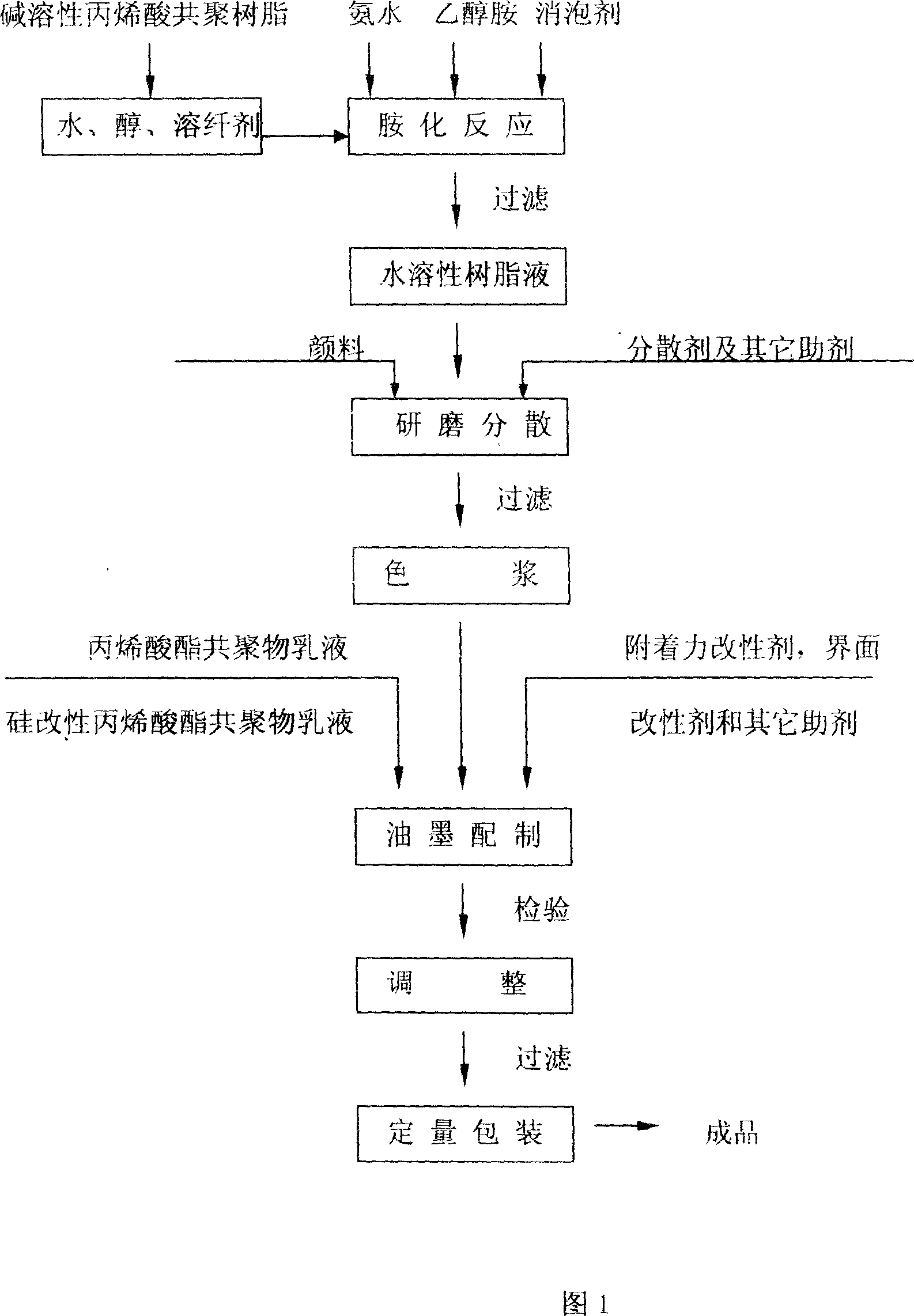

Method used

Image

Examples

example 3

[0019] Alkali-soluble acrylic copolymer resin 30.0 30.0 30.0

[0020] Purified water 50.0 50.0 50.0

[0021] Ethyl cellosolve 3.0 3.0 3.0

[0022] Isopropanol 9.0 5.0

[0023] Ethanol 9.0 4.0

[0024] Ethanolamine 8 8 8

[0025] Antifoam 1 1 1

[0026] Total 100.0 100.0 100.0

[0027] Operation method:

[0028] Put pure water, ethyl cellosolve, isopropanol or ethanol or the mixture of the two into the enamel reaction kettle according to the proportion, start stirring, slowly add alkali-soluble acrylic copolymer resin, and stir evenly. Then add the weighed ethanolamine slowly for about 20-30 minutes to carry out the amination reaction, control the temperature 9.0; the amination reaction is about 2 hours, during which the pH value of the solution is constantly checked until the solution The pH value of the resin is stable at 8.5~9.0, and the resin is completely aminated and dissolved. Add the defoamer and stir for 10 minutes, and then it can be filtered and put into a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Freshness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com