Slurry for forming insulating layer, separator for electrochemical device, method for producing the same, and electrochemical device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

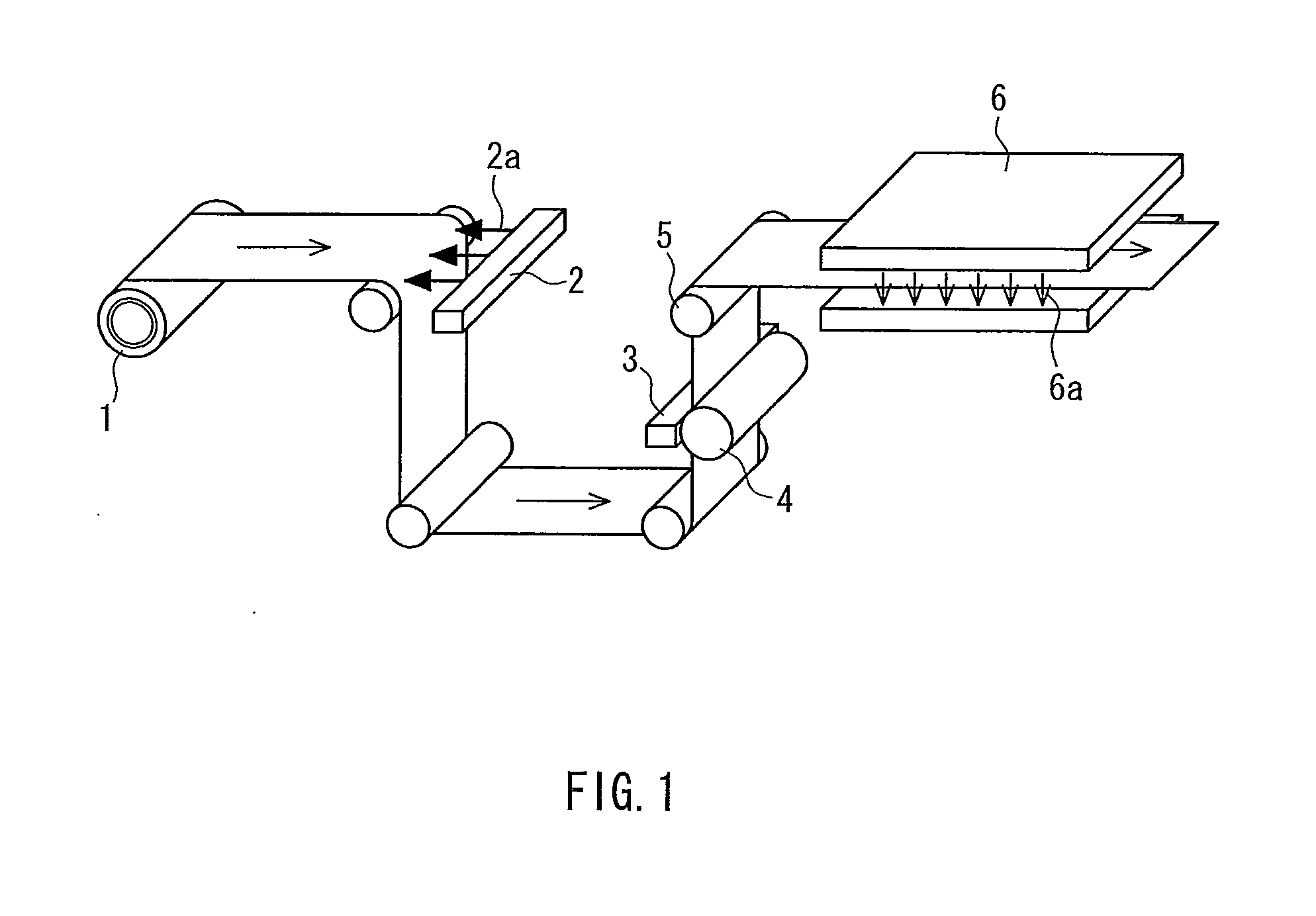

Image

Examples

embodiment 1

[0022]First, an embodiment of a slurry for forming an insulating layer of the present invention will be described. The slurry for forming an insulating layer of the present invention is used to form a porous insulating layer that can constitute a separator for an electrochemical device, and is obtained by dispersing at least heat-resistant insulating fine particles (which may be simply referred to as “insulating fine particles” in the following) and a thickening agent in a dispersion medium. The thickening agent may be dissolved in the dispersion medium.

[0023]In the separator for an electrochemical device that is produced using the slurry for forming an insulating layer of the present invention, the insulating fine particles have the effects of increasing the heat resistance of the separator, improving the dimensional stability of the separator at high temperatures, and suppressing the occurrence of a small short circuit due to the lithium dendrite.

[0024]The insulating fine particle...

embodiment 2

[0067]Next, an embodiment of a separator for an electrochemical device of the present invention will be described. The separator for an electrochemical device of the present invention includes a porous insulating layer. The insulating layer includes heat-resistant insulating fine particles and a binder. The proportion of particles with a particle size of 1 μm or less in the insulating fine particles is 30 vol % or more and the proportion of particles with a particle size of 3 μm or more in the insulating fine particles is 10 vol % or less.

[0068]More specifically, the separator includes the insulating layer that has both ion permeability and heat resistance and is formed by the steps of: applying the slurry for forming an insulating layer of the present invention, as described in Embodiment 1, to at least one base selected from the group consisting of a positive electrode for an electrochemical device, a negative electrode for an electrochemical device, and a porous base material; an...

embodiment 3

[0115]Next, an electrochemical device of the present invention will be described. The electrochemical device of the present invention includes the separator of the present invention having good heat resistance, as described in Embodiment 2. Therefore, even if the temperature in the electrochemical device becomes high, it is possible to suppress an internal short circuit caused by thermal shrinkage of the separator. Moreover, it is also possible to suppress a small short circuit caused by a deposition of the lithium dendrite by the separator. Thus, electrochemical device can achieve excellent safety and reliability.

[0116]The intended use of the electrochemical device of the present invention is not particularly limited. The electrochemical device can be suitably used in any application requiring safety at high temperatures such as a lithium battery (primary and secondary batteries) including an organic electrolyte or a super capacitor. There is no particular limitation to the configu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com