Preparation method of carbon material-supported ruthenium metal catalyst containing barium auxiliary agent

A technology of metal catalysts and ruthenium catalysts, which is applied in the field of preparation of ruthenium catalysts, can solve problems affecting the stability of ruthenium catalysts and ammonia synthesis activity, and achieve good industrial application prospects, improved activity, and superior heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

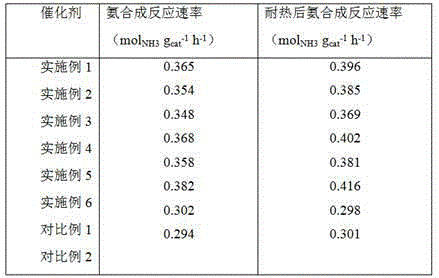

Examples

Embodiment 1

[0018] Take 5g of graphitized activated carbon, impregnate an equal volume of 0.05g / mL ruthenium chloride solution to a mass ratio of Ru:C of 0.10:1, dry at 120°C for 4 hours; reduce in a hydrogen atmosphere at 500°C for 6 hours , cooled to room temperature in the above atmosphere; impregnated the obtained sample with barium nitrate aqueous solution to a molar ratio of Ba to Ru of 0.6:1, dried at 120°C for 4 hours; heat-treated at 500°C in methane gas for 2 hours, after cooling It can be reduced at 430°C for 6 hours in a hydrogen atmosphere.

Embodiment 2

[0020] Take 5g of graphitized activated carbon, impregnate an equal volume of 0.05g / mL ruthenium chloride solution to a mass ratio of Ru:C of 0.10:1, dry at 120°C for 4 hours; reduce in a hydrogen atmosphere at 500°C for 6 hours , cooled to room temperature in the above-mentioned atmosphere; impregnating the obtained sample with barium nitrate aqueous solution to a molar ratio of Ba to Ru of 0.6:1, and drying at 120°C for 4 hours; : 1) Heat treatment at 500°C for 2 hours, then reduce in hydrogen atmosphere at 450°C for 6 hours after cooling.

Embodiment 3

[0022] Take 5g of graphitized activated carbon, impregnate an equal volume of 0.05g / mL ruthenium chloride solution to a mass ratio of Ru:C of 0.08:1, dry at 120°C for 4 hours; reduce in a hydrogen atmosphere at 500°C for 6 hours , cooled to room temperature in the above-mentioned atmosphere; impregnated the obtained sample with barium nitrate aqueous solution to a molar ratio of Ba to Ru of 0.3:1, and dried at 120°C for 4 hours; : 1) heat treatment at 400°C for 30 hours, and then reduce in a hydrogen atmosphere at 450°C for 16 hours after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com