Welding gun for rotating arc gas metal arc welding

A technology of melting electrode gas and rotating arc, used in arc welding equipment, electrode accessories, electrode support devices, etc., can solve the problems of high cost, complex eccentric mechanism, easy deformation, etc., to prolong life, reduce maintenance requirements, welding process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

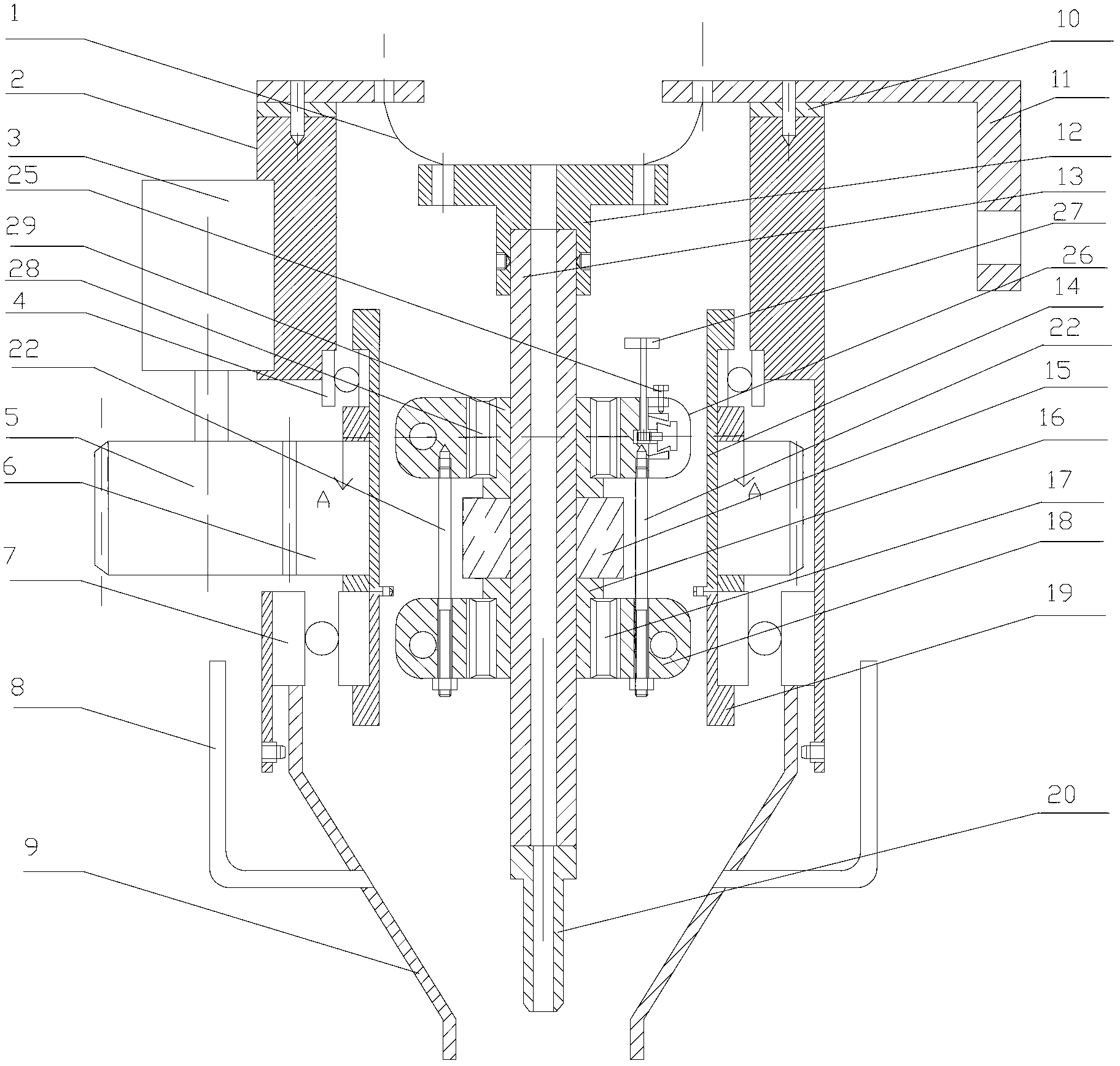

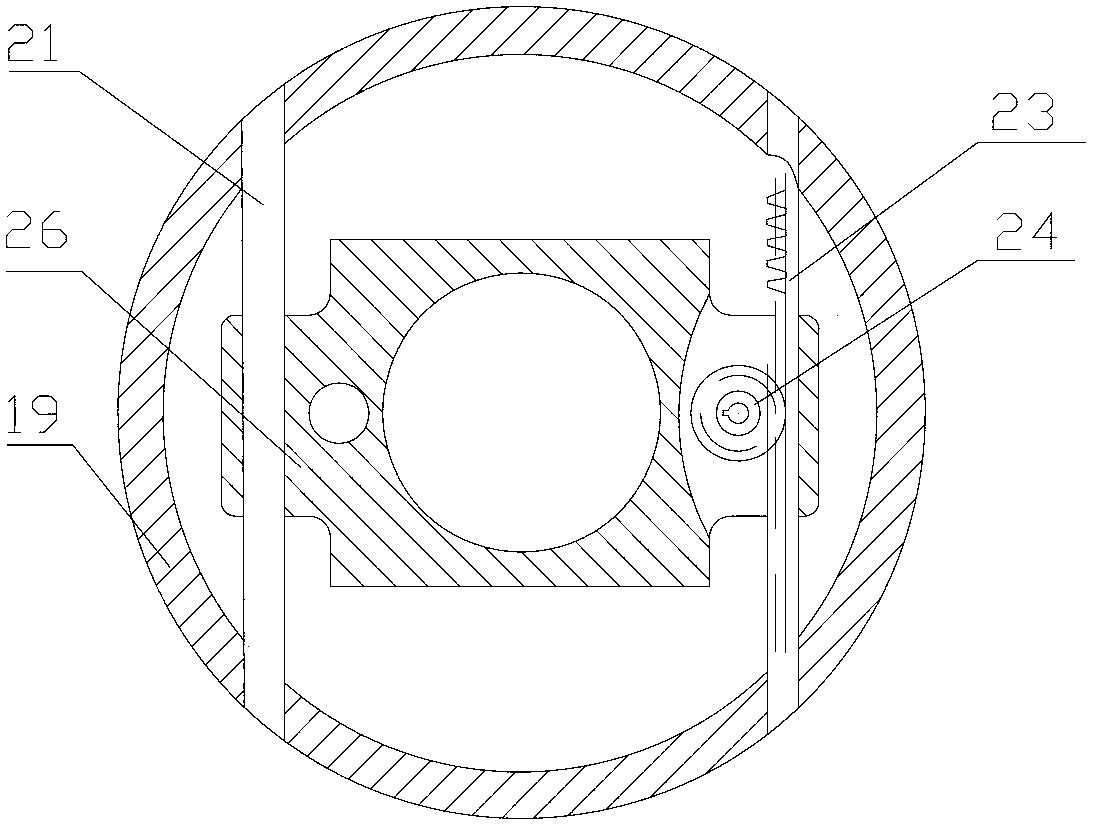

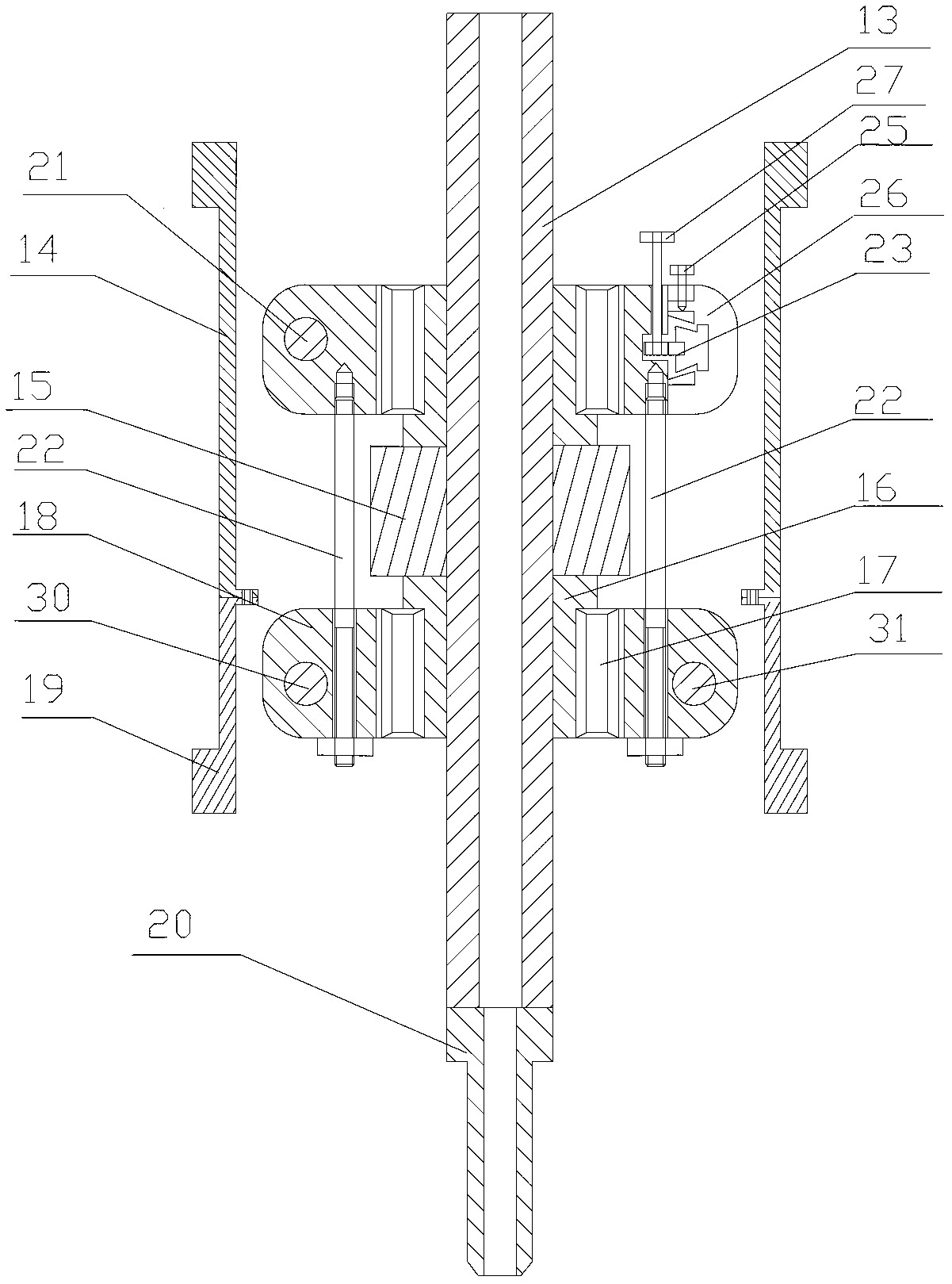

[0024] Such as figure 1 , figure 2 , image 3 As shown, the rotating arc melting electrode gas shielded welding torch of the present invention includes a driving mechanism, a welding torch outer tube 2, and an eccentric component installed in the welding torch outer tube 2; the eccentric component includes an upper inner tube 14, a lower inner tube 19 and an eccentricity adjustment mechanism, Among them, the upper inner cylinder 14 and the lower inner cylinder 19 are connected by screws;

[0025] The eccentricity adjustment mechanism includes an upper sliding block 26 installed in the upper inner cylinder 14 and the lower inner cylinder 19, a lower sliding block 18, an upper rolling bearing 28 installed in the center of the upper sliding block 26, an insulating ring 29 embedded in the upper rolling bearing 28, a lower The lower rolling bearing 17 installed in the center of the slider, the insulating ring 16 embedded in the lower rolling bearing 17, and the hollow shaft 13 instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com