Flux-cored wire for austenitic stainless steel all-position welding

An austenitic stainless steel, all-position technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of increased flat welding spatter, sacrificial welding wire flat welding manufacturability, etc., to achieve less welding spatter, Good slag removal and high arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

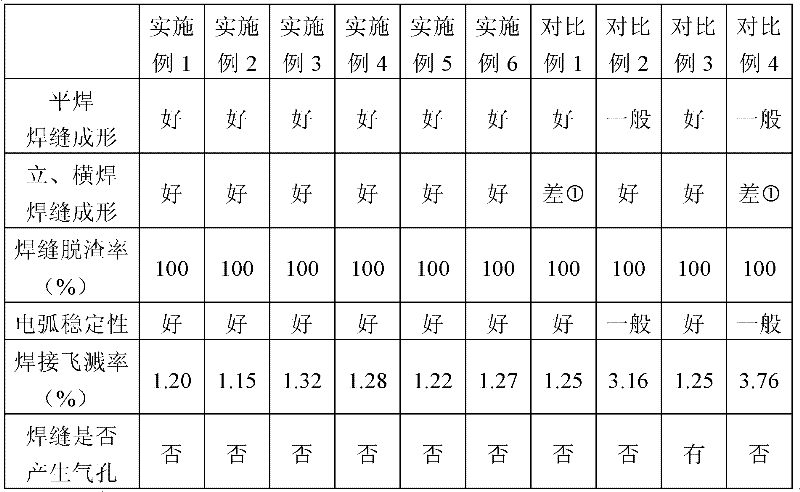

Examples

Embodiment 1

[0042] Select austenitic stainless steel strip 304L with a thickness of 0.4mm, a width of 10mm, and a weight of 3545g, and roll it into a U shape. 200g of metal chromium powder, 70g of metal nickel powder, 20g of electrolytic metal manganese, 30g of aluminum powder, 5g of titanium iron, 320g rutile, 10g quartz, 20g zircon sand, 40g albite feldspar, 20g potassium feldspar, 10g cryolite, 10g lithium carbonate, 3g bismuth oxide, 242g iron powder, a total of 1000g powder, mixed evenly and added to the U-shaped tank, The filling rate is 22%. After the joint is closed, the diameter is reduced, bright annealed, and then reduced. The final diameter of the finished welding wire is 0.9mm.

Embodiment 2

[0044]Select austenitic stainless steel strip 304L with a thickness of 0.4mm, a width of 10mm, and a weight of 3545g, and roll it into a U shape. 230g of metal chromium powder, 85g of metal nickel powder, 40g of electrolytic metal manganese, 40g of aluminum powder, 10g of titanium iron, 340g rutile, 20g quartz, 40g zircon sand, 60g albite, 40g potassium feldspar, 15g cryolite, 15g carbonate, 4g bismuth oxide, 61g iron powder, a total of 1000g powder, mix well and add to the U-shaped tank , The filling rate is 22%. After closing, the diameter is reduced, bright annealed, and then reduced. The final diameter of the finished welding wire is 1.2mm.

Embodiment 3

[0046] Select austenitic stainless steel strip 304L with a thickness of 0.4mm, a width of 10mm, and a weight of 3348g, and roll it into a U shape, 220g of metal chromium powder, 75g of metal nickel powder, 25g of electrolytic metal manganese, 32g of aluminum powder, 6g of titanium iron, 330g rutile, 15g quartz, 28g zircon sand, 45g albite feldspar, 30g potassium feldspar, 12g cryolite, 12g lithium carbonate, 4g bismuth oxide, 166g iron powder, a total of 1000g powder, mixed evenly and added to the U-shaped tank, The filling rate is 23%. After the joint is closed, it undergoes diameter reduction, bright annealing, and then diameter reduction. The final diameter of the finished welding wire is 0.9mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com