A Laser Welding Process for Improving the Fitting Margin of Thin Plate Titanium Alloy Tailored Welding

A laser welding and titanium alloy technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of restricting the development of laser tailor welding technology, increasing equipment investment, and increasing the weight of structural parts, so as to reduce gap sensitivity , Increase the cooling rate, improve the effect of weld forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

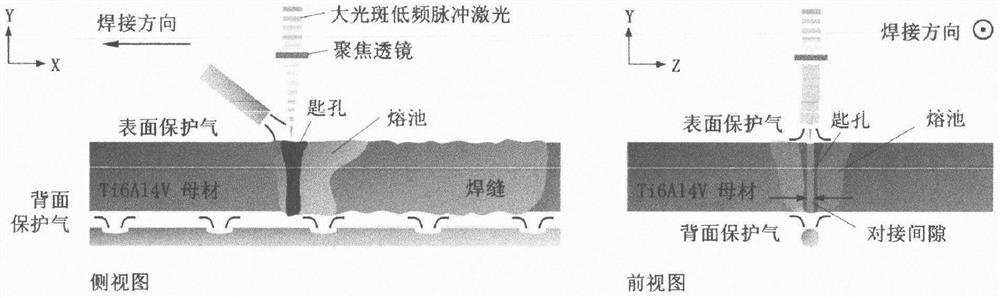

[0021] 1.2mm Ti6A14V titanium alloy thin plate is used as the welding base material, and the sample size is processed to 100mm×50mm by wire cutting. The ruler sets the assembly gap to 0.2mm.

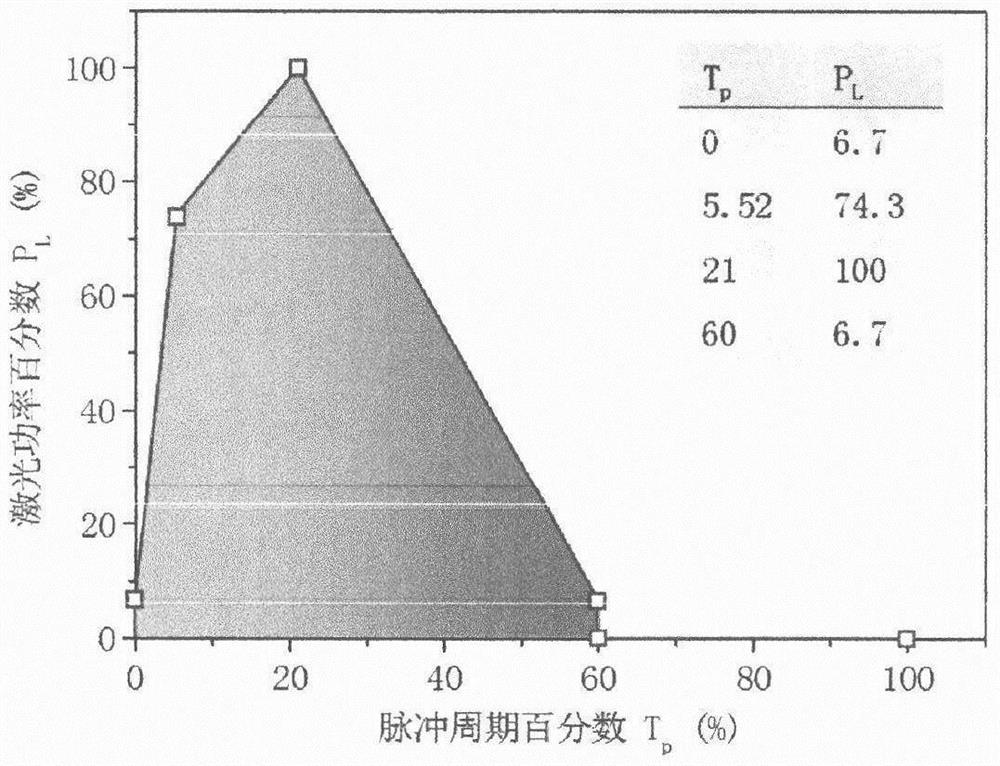

[0022] The welding adopts Trumpf Trudisc 4001 disc laser, the laser power is 2.2kW, the welding speed is 1.8m / min, the pulse frequency is 20Hz, the duty cycle is 0.6, the defocus amount is 0, and the focal spot diameter is 700μm. The pulse waveform is the default waveform of the laser, such as figure 2 As shown; the protective gas is pure Ar, the surface flow rate is 30L / min, and the back flow rate is 15L / min.

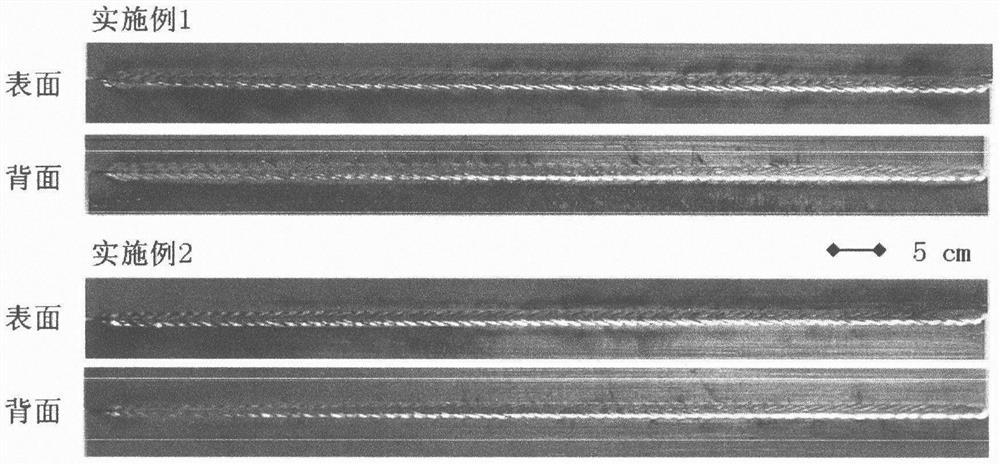

[0023] After welding, photograph the weld surface and root formation; prepare weld metallographic samples through processes such as wire cutting, inlaying, grinding, polishing, and corrosion, and photograph the cross-sectional metallographic appearance.

Embodiment 2

[0025] 1.2mm Ti6A14V titanium alloy thin plate is used as the welding base material, and the sample size is processed to 100mm×50mm by wire cutting. The ruler sets the assembly gap to 0.3mm.

[0026] The welding adopts Trumpf Trudisc 4001 disc laser, the laser power is 2.4kW, the welding speed is 1.8m / min, the pulse frequency is 20Hz, the duty cycle is 0.6, the defocus amount is 0, and the focal spot diameter is 700μm. The pulse waveform is the default waveform of the laser, such as figure 2 As shown; the protective gas is pure Ar, the surface flow rate is 30L / min, and the back flow rate is 15L / min.

[0027] After welding, photograph the weld surface and root formation; prepare weld metallographic samples through processes such as wire cutting, inlaying, grinding, polishing, and corrosion, and photograph the cross-sectional metallographic appearance.

[0028] The surface and back appearance of the welded joint obtained in embodiment 1-2 are as follows: image 3 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com