Chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire and preparing method thereof

A technology of high-alloy steel and flux-cored welding wire, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of mill shutdown and maintenance, affecting production efficiency and product quality, etc., to reduce the hardening tendency and improve welding. The effect of reducing seam forming quality and oxidative burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

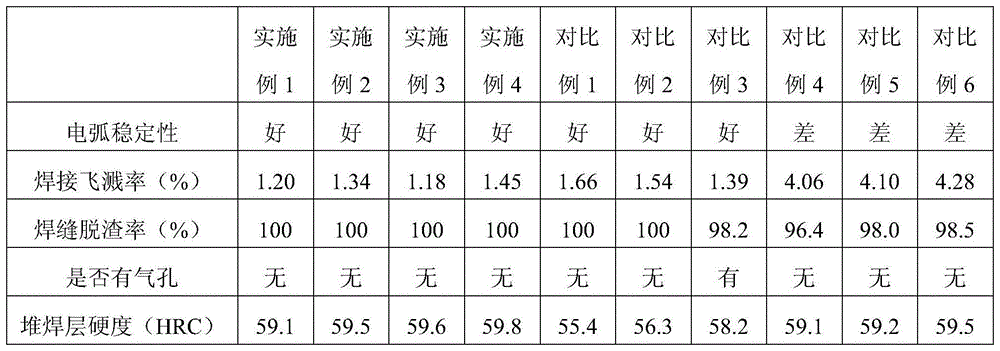

Examples

Embodiment 1

[0033] 220g high-carbon ferrochromium, 410g ferro-titanium, 15g metal manganese powder, 21g metal molybdenum powder, 37g graphite, 38g silicon-calcium alloy, 25g zircon sand, 90g fluorite, 1g boron carbide, 143g iron powder, 1000g powder in total, Choose a carbon steel strip with a thickness of 0.3mm and a width of 16mm, with a tensile strength of 315MPa and an elongation of 41%, and roll it into a U shape. After the powder is mixed evenly, add it to the U-shaped groove, and the filling factor of the powder is 40%. , After the steel strip is closed, it is drawn and reduced in five passes of φ4.32mm, φ3.51mm, φ2.87mm, φ2.34mm, and φ1.97mm, and finally a finished welding wire with a diameter of 2.0mm is obtained.

Embodiment 2

[0035] 230g high-carbon ferrochromium, 400g ferro-titanium, 15g metal manganese powder, 20g metal molybdenum powder, 38g graphite, 40g silicon-calcium alloy, 27g zircon sand, 95g fluorite, 2g boron carbide, 133g iron powder, a total of 1000g powder, Select a carbon steel strip with a thickness of 0.3mm and a width of 16mm, with a tensile strength of 320MPa and an elongation of 42%, and roll it into a U shape. After the powder is mixed evenly, add it to the U-shaped groove, and the filling factor of the powder is 41%. , The steel strip joint is drawn and reduced in five passes of φ4.32mm, φ3.51mm, φ2.87mm, φ2.34mm, φ1.97mm, and finally a finished welding wire with a diameter of 2.0mm is obtained.

Embodiment 3

[0037]200g high-carbon ferrochromium, 380g ferro-titanium, 12g metal manganese powder, 20g metal molybdenum powder, 35g graphite, 25g silicon-calcium alloy, 20g zircon sand, 80g fluorite, 1g boron carbide, 227g iron powder, a total of 1000g powder, Choose a carbon steel strip with a thickness of 0.3mm and a width of 16mm, with a tensile strength of 330MPa and an elongation of 45%, and roll it into a U shape. After the powder is mixed evenly, add it to the U-shaped groove, and the filling factor of the powder is 38%. , After the steel strip is closed, it is drawn and reduced in five passes of φ4.32mm, φ3.51mm, φ2.87mm, φ2.34mm, and φ1.97mm, and finally a finished welding wire with a diameter of 2.0mm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com