Gas-assisted resistance spot welding device and its cooling and heating method

A resistance spot welding and gas-assisted technology, used in auxiliary devices, resistance welding equipment, auxiliary welding equipment, etc. Welding method, not using popularization, not suitable for spot welding, etc., to achieve the effect of wide range of use, easy popularization and application, and uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

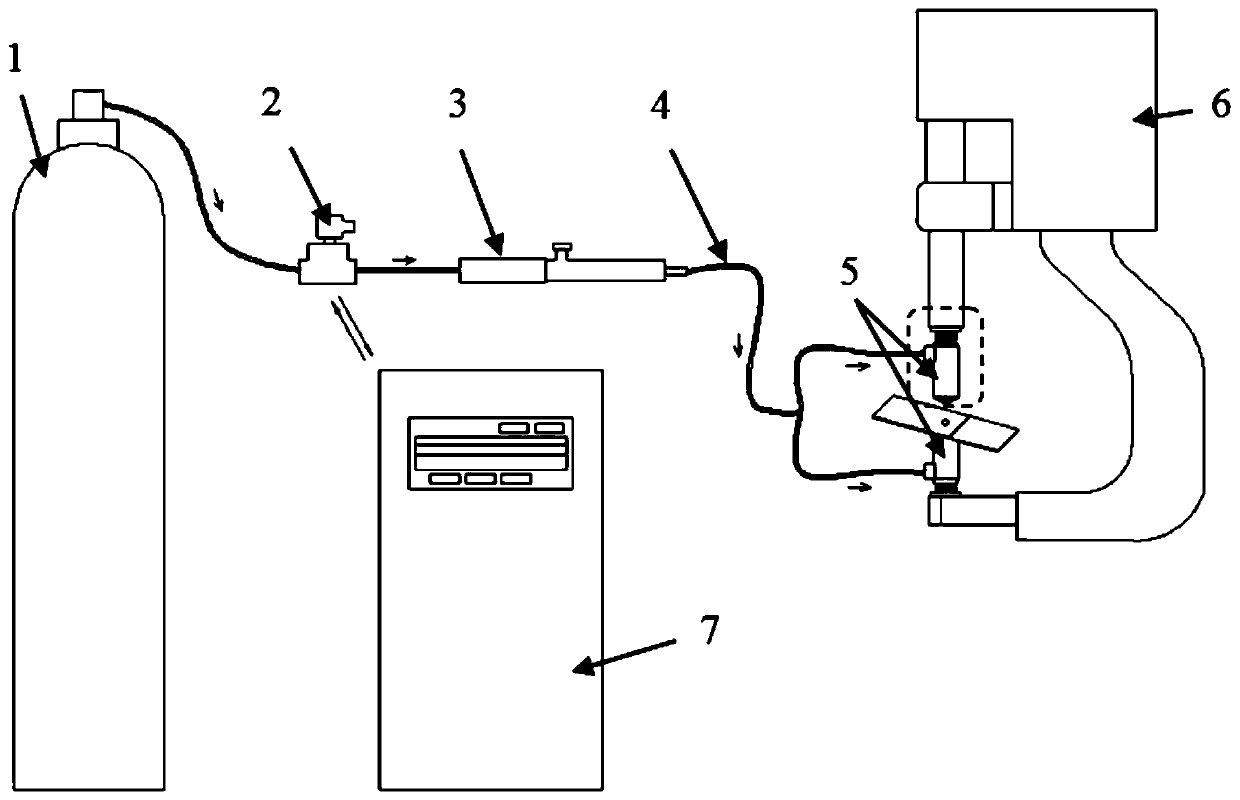

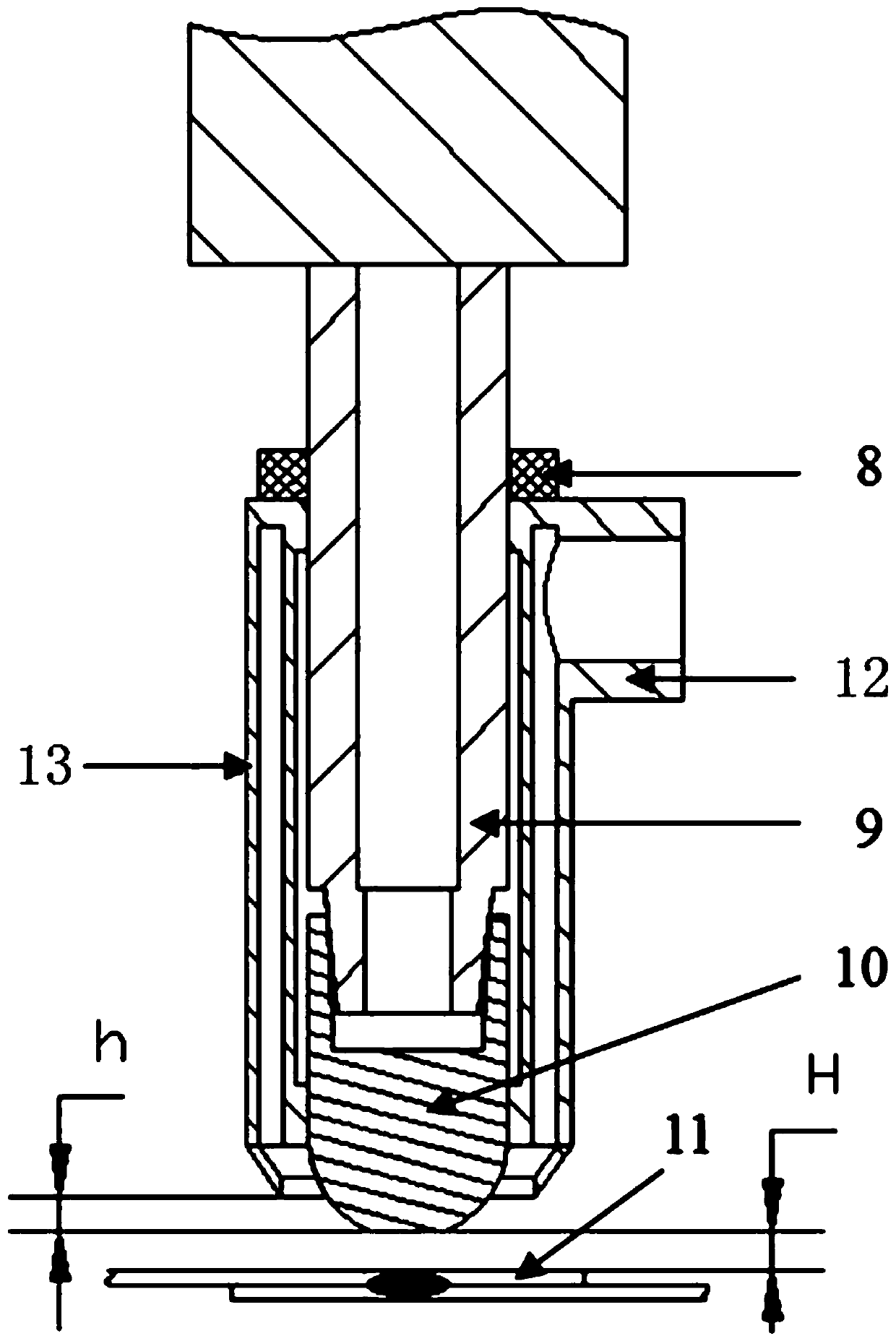

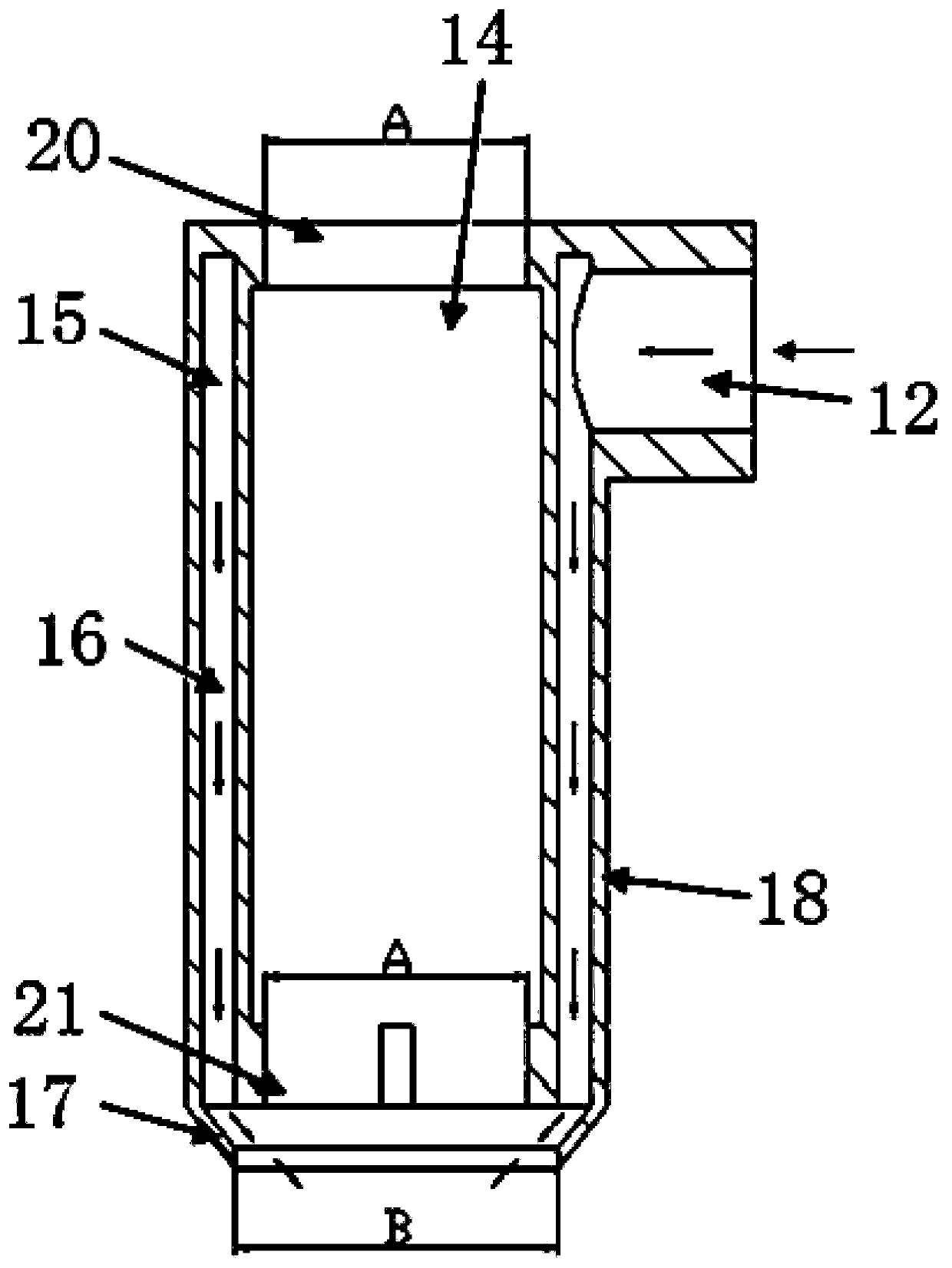

[0051] like figure 1 and figure 2 As shown, this embodiment includes: a gas cylinder 1, a solenoid valve 2, a vortex tube 3, a gas pipeline 4, a nozzle 5, a resistance spot welding system 6, a control system 7, a nozzle fixing device 8, an electrode rod 9, and an electrode cap 10 and workpiece 11. Wherein: the resistance spot welding system 6 is connected with the control system 7 and transmits welding control signals, the control system 7 is connected with the solenoid valve 2 and controls the startup and closing of the solenoid valve 2, when the solenoid valve 2 is started, the gas in the gas cylinder 1 can pass through The cold air end of the solenoid valve 2 and the scroll tube 3 enters the nozzle 5. The workpiece 11 is fixed on the clamping device. figure 2 Yes figure 1 A partial enlarged view of the inner part of the middle dashed frame, the nozzle 5 is connected with the nozzle fixing device 8 by screws or snaps, and is fixed on the electrode rod 9 by the nozzle f...

Embodiment 2

[0063] In this embodiment, the upper metal plate is aluminum alloy AA6061-T6, the lower metal plate is galvanized dual-phase steel plate DP590, the thickness of the plate is 1.2mm, the aluminum plate is mechanically polished to remove the oxide layer on the surface, and the metal plate is removed by acetone Oil stains on the surface.

[0064] Process parameters: welding current is 8kA, welding time is 160ms, electrode pressure is 3.5kN, pre-pressure time is 100ms, pressure holding time is 200ms, argon gas is used as cooling gas, its flow rate is 20L / min, and the inlet pressure is 5.5bar. Other parameters are the same as in Example 1.

[0065] In this embodiment, due to the welding of dissimilar metals, the physical properties such as hardness, melting point and thermal conductivity of the two metals are different. The upper and lower plates can be cooled with different degrees. After the gas comes out of the gas cylinder, it is divided into two paths. Solenoid valves and cool...

Embodiment 3

[0073] The system can also be used for auxiliary heating of welding workpieces.

[0074] The upper and lower metal plates of this embodiment are all DP980 dual-phase steel, the thickness of the plate: 1.2 mm, and the oil stain on the surface of the metal plate is removed with acetone reagent.

[0075] Process parameters: welding current is 7.5kA, welding time is 200ms, electrode pressure is 4kN, preload time is 100ms, pressure holding time is 200ms, argon gas is used as cooling gas, and its flow rate is 20L / min, and other parameters are the same as in Example 1.

[0076] The difference between the components of this embodiment and the first embodiment is that the outlet gas of the hot gas end of the vortex tube 3 is used as the auxiliary gas.

[0077] The welding process of this embodiment is as follows Figure 8 As shown in (a) to (f):

[0078] 1) Place the metal plate on top of another metal plate and clamp it by the clamping device;

[0079] 2) The welding torch moves to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com