High-toughness gas shielded arc welding wire for ultra-low heat input automatic welding, and welding method thereof

A gas shielded welding wire, automatic welding technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of weld metal embrittlement, impact energy and CTOD fracture toughness decline, can not meet and other problems, to achieve low temperature impact toughness improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with embodiment.

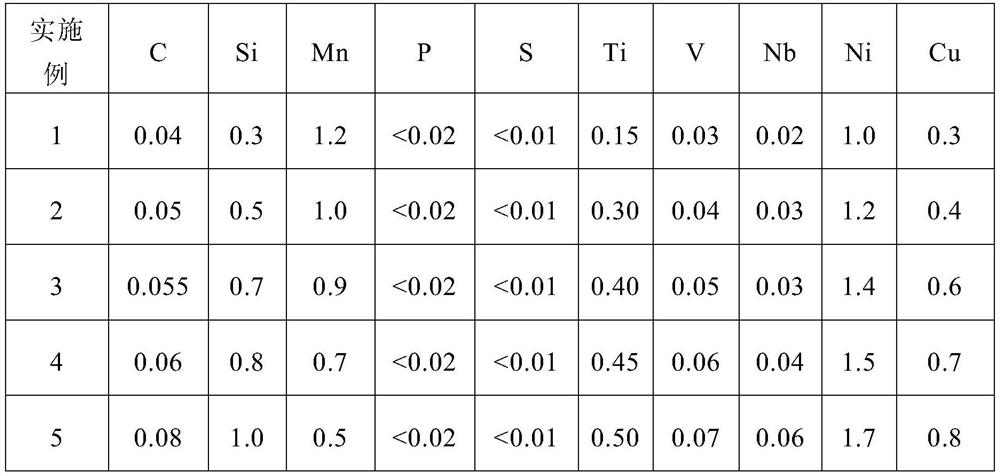

[0051] Refer to Table 1 for the composition of the gas-shielded solid welding wire of the present invention. Table 1 shows the chemical composition ratio of 5 different gas-shielded welding wires suitable for ultra-low heat input welding.

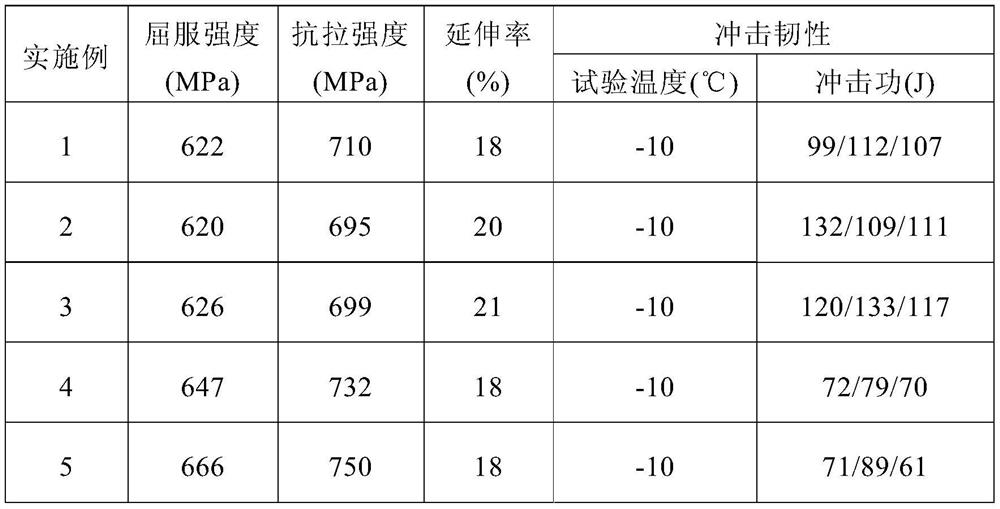

[0052] The API 5L X70M pipeline steel pipe with a wall thickness of 23mm is selected, and the gas-shielded solid welding wire of the present invention is used for automatic welding with an ultra-low heat input of no more than 0.25kJ / mm. The steel pipe adopts compound V-groove. The bevel angle is 5±2°, and the depth is 17mm. The down bevel angle is 30°±2°, and the depth is 5mm. The blunt edge of the groove is 1±0.5mm. The back of the root weld is formed using a copper backing to aid in the welding process. Use 80% Ar+20% CO 2 Mixed gas protection. Before welding, it is necessary to grind and clean the welding groove and the 20mm range on both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com