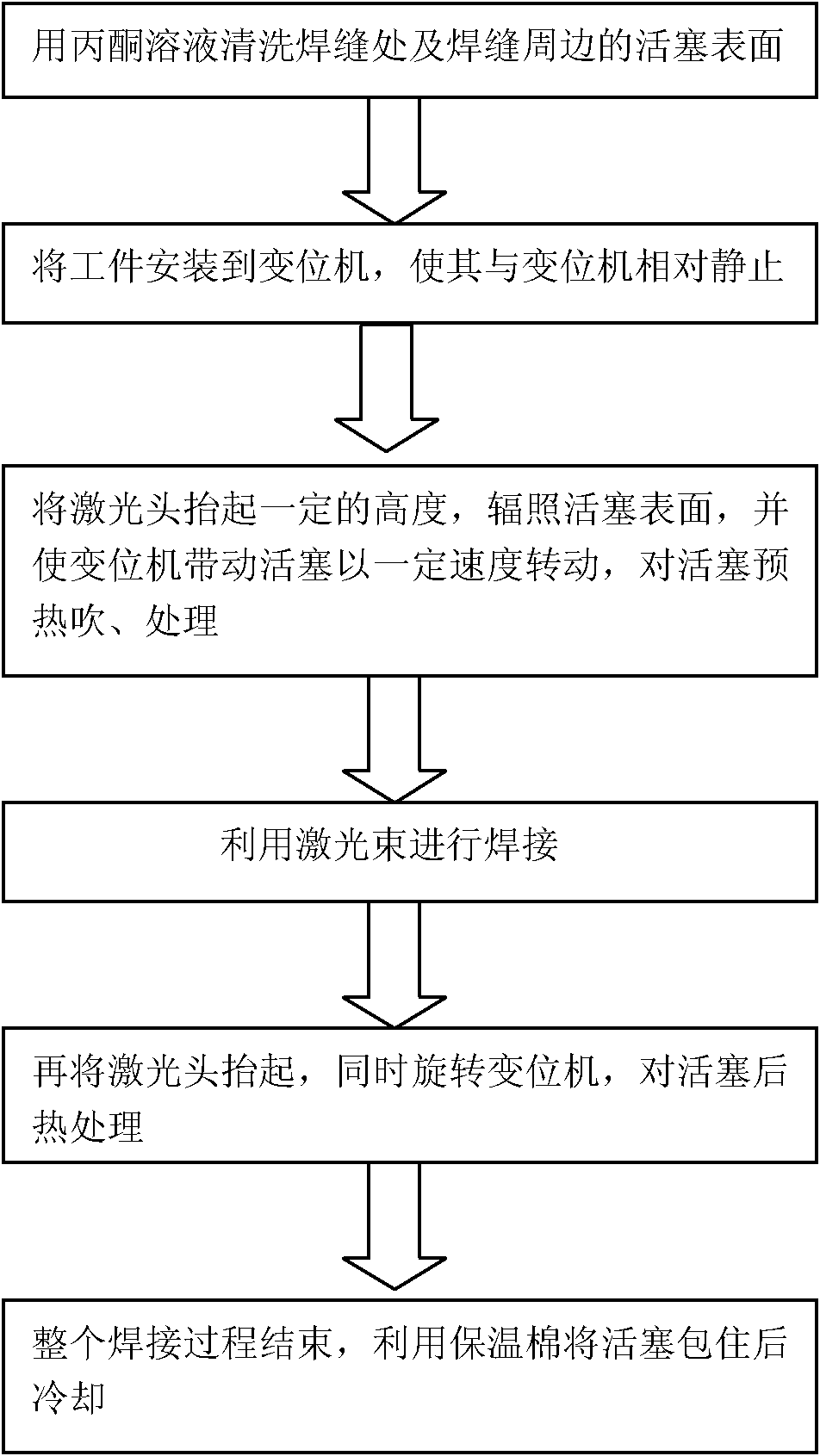

Method for welding piston by laser with laser heat treatment

A technology of laser heat treatment and laser welding, which is applied in the field of laser heat treatment, can solve problems such as delayed cracks and easy cracking of weld seams, and achieve the effects of controllable speed, simplified process, and improved weld seam forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention controls the rotation of the positioner, the raising and lowering of the laser head or the output of the laser through the numerical control system of the numerical control machine tool. During laser preheating or post-heat treatment, the piston and the positioner remain relatively stationary, and the piston is driven by the positioner to rotate; the positioner can rotate clockwise and counterclockwise, and its control is integrated into the numerical control system, and its speed can be adjusted. control. The control of the laser is integrated in the numerical control system, and the light emission time and light output power can be adjusted in the numerical control system.

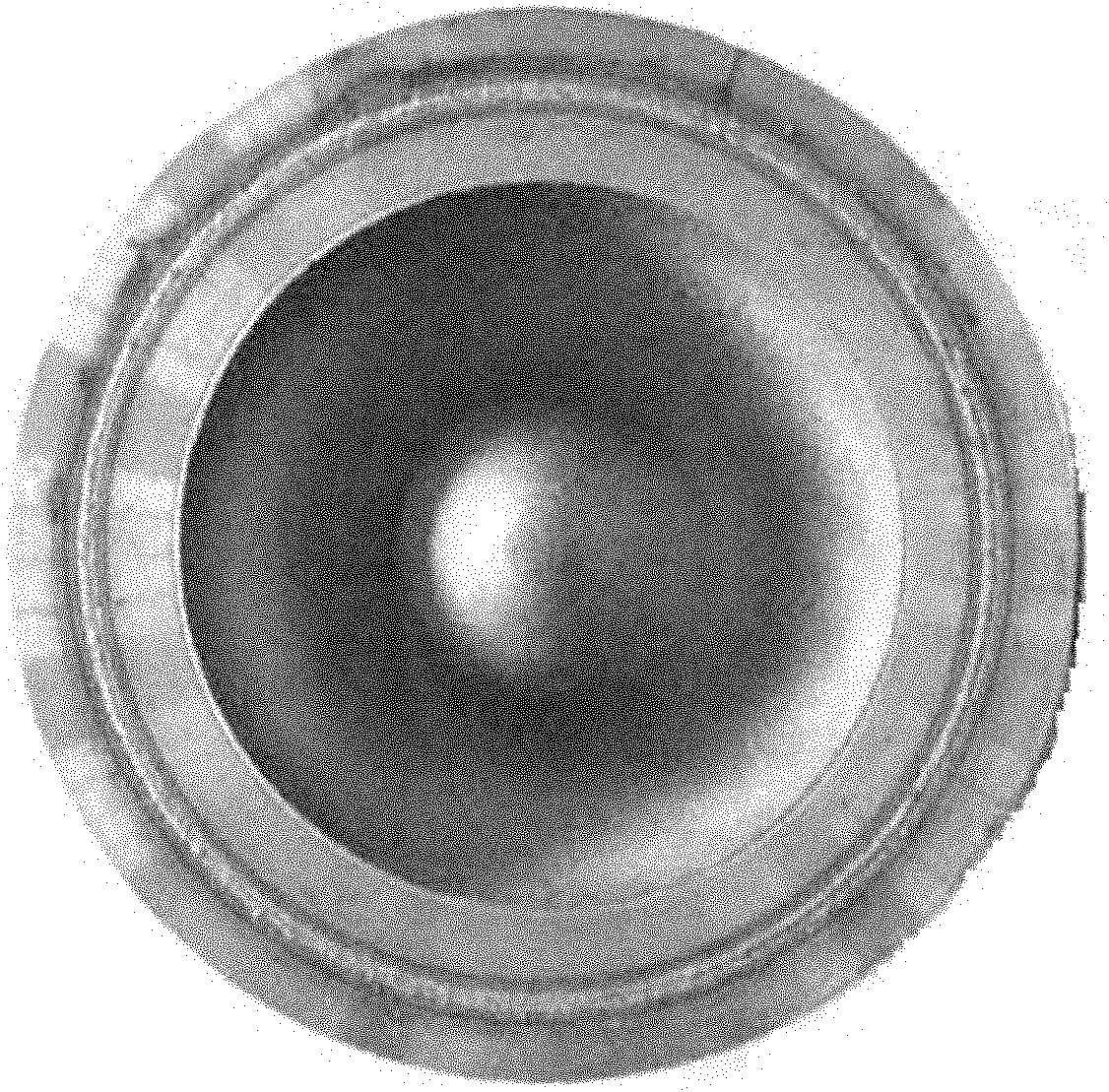

[0023] According to the present invention, it is actually applied to the laser welding heat treatment of 42CrMo piston ring sleeve and piston head. 42CrMo piston, its carbon content belongs to the range of medium carbon steel, and the laser welding of medium and high carbon steel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com