Pipeline steel two-in-one butt weld pipeline deep penetration high-speed welding process method

A butt weld and welding process technology, applied in the field of automatic welding of pipelines, can solve problems such as large penetration depth, low welding efficiency, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment provides a pipeline steel two-to-one butt weld pipeline deep penetration high-speed welding process method, specifically as follows: 1. Welding equipment and materials

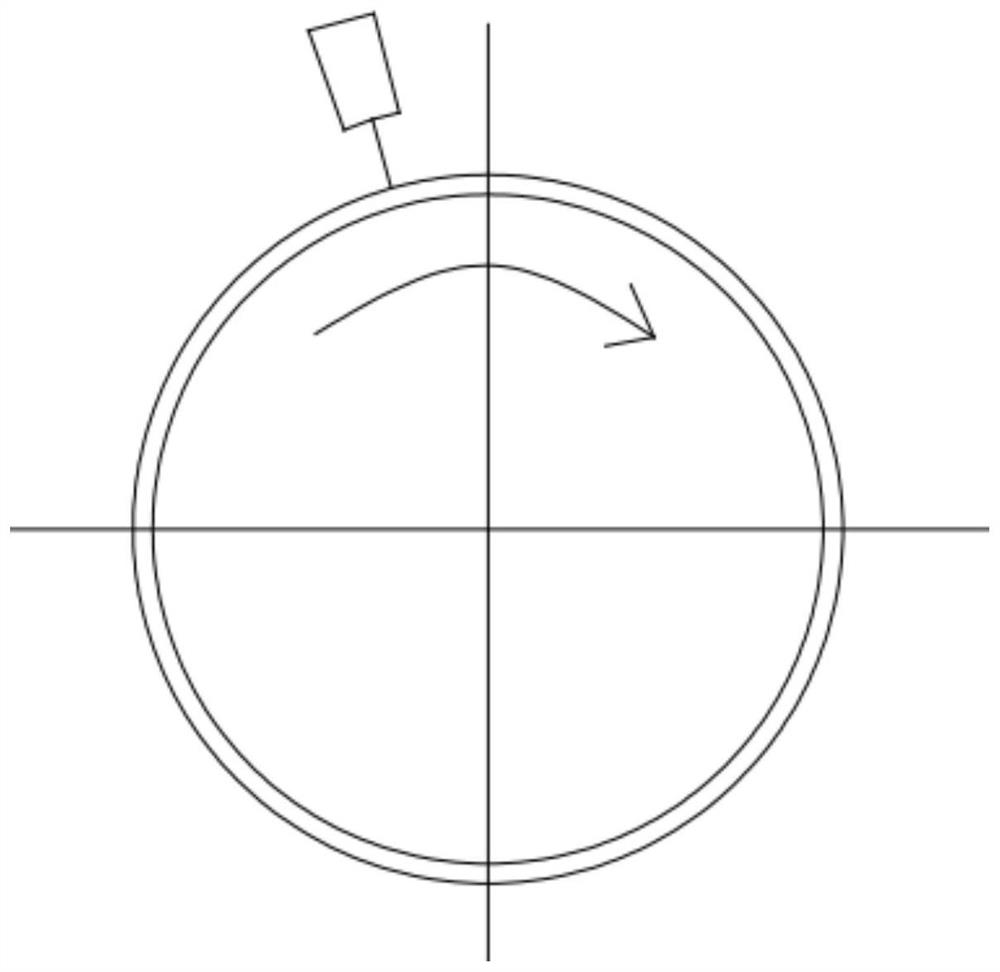

[0026] (1) The welding equipment is used in combination with electric welding machine and 219 cantilever welding positioner;

[0027] (2) The base material of the welding material is Q235B (low alloy steel), the specification is Φ273×10mm, the yield strength is >235Mpa, and the tensile strength is >415Mpa; the low alloy steel gas shielded welding wire JQ·MG50- with a wire diameter of Φ1.2mm is used 6.

[0028] 2. Preparation before welding

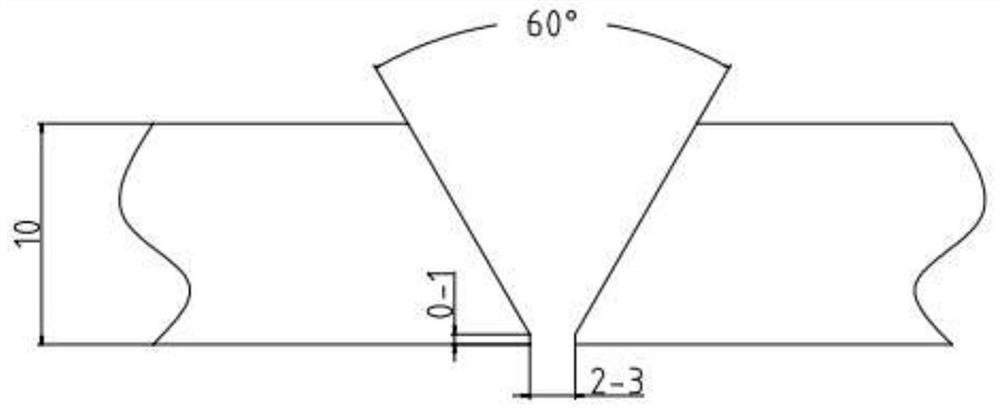

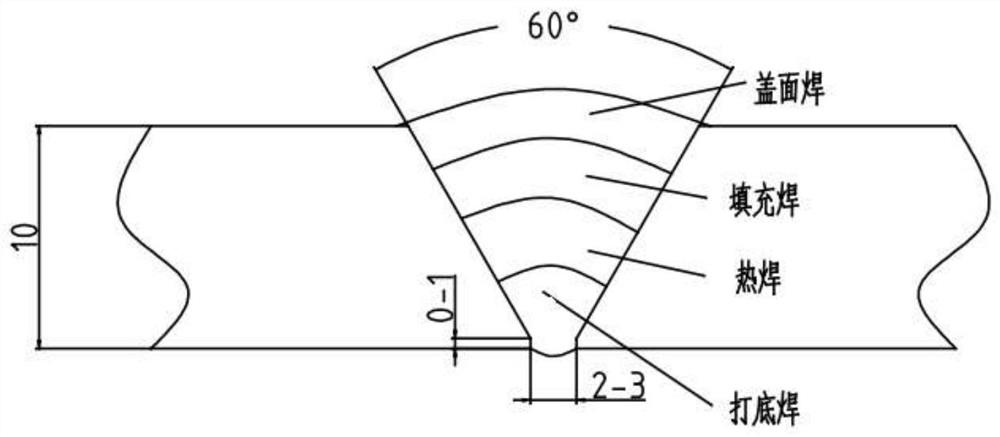

[0029] (1) Groove processing: V-shaped grooves are made on Q235B low-alloy steel by lathe processing. The groove angle is 30° on one side, the blunt side is 0-1mm, and the gap is 2-3mm. The roundness of the pipe needs to be corrected during the groove processing process. , to ensure that the amount of misalignment ≤ 1.5mm, such as figure 1 shown; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com