Surface preprocessing method for laser welding of aluminum alloy

A surface pretreatment and laser welding technology, which is applied in laser welding equipment, welding equipment, cleaning methods and appliances, etc., can solve the problems of difficult removal of surface oxide film and high laser reflectivity, and achieve low reflectivity, high cleanliness, Easy to automate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

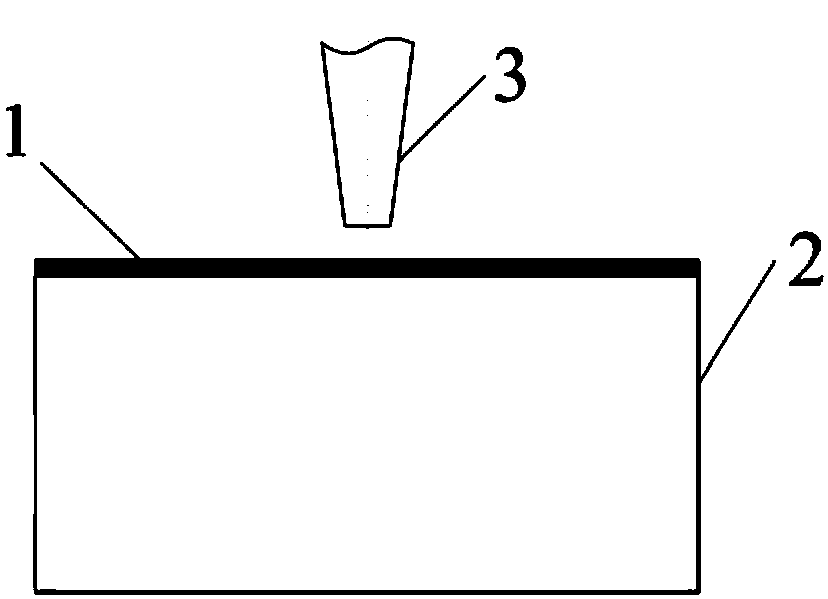

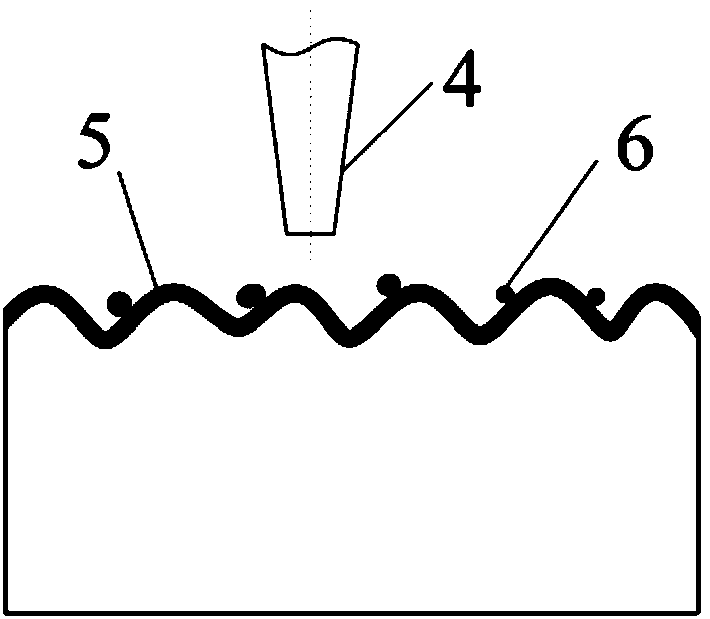

[0042] The material to be welded is a 10mm thick 7A52 aluminum alloy plate. Both the surface texturing and cleaning treatment use an IPG fiber laser with a pulse width of 100ns, a pulse frequency of 30kHz, and a wavelength of 1064nm. The linear laser beam is controlled by the robot to move in the vertical direction.

[0043] Process parameters of surface texturing: laser energy density is 5.2J / cm 2 , the scanning speed is 1500mm / s, the moving speed is 0.5mm / s, and the linear spot size is 50mm. Surface cleaning process parameters: laser energy density is 0.9J / cm 2 , the scanning speed is 1000mm / s, the moving speed is 0.2mm / s, and the linear spot size is 50mm.

[0044] The three-dimensional morphology of the aluminum alloy surface before and after pretreatment is as follows: Figure 6 and Figure 7 shown. The mass fraction of oxygen element on the unpretreated aluminum alloy surface is 16.54%, and the surface roughness is 0.82 μm. is 3.21 μm.

[0045] The mass fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com