High-strength steel welding rod for hydroelectric engineering and preparation method for high-strength steel welding rod

A technology for hydropower engineering and high-strength steel, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problem that the strength level cannot be reached, the strength requirements of steel used in hydropower engineering, the tensile strength of chrome molybdenum hydrogen steel electrodes, Yield strength vertical welding large line energy impact requirements do not meet technical requirements and other problems, to achieve good welding process performance, improve the overall performance of the weld, and the effect of arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

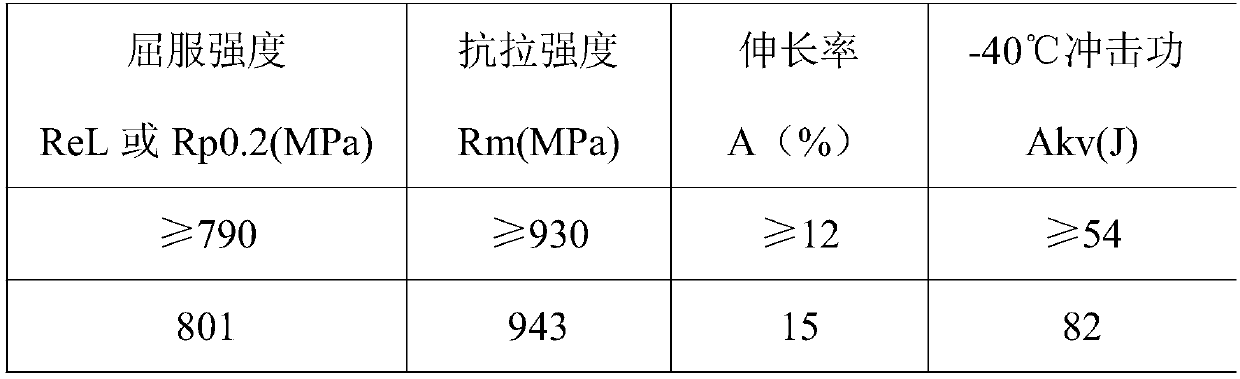

Embodiment 1

[0045] A low-alloy high-strength steel electrode for hydropower engineering according to the present invention needs to strictly control the content of impurity elements in the deposited metal. The electrode is produced by using a rod wire that meets the following composition requirements, and the alkaline slag system is used to ensure that the deposited metal is obtained. mechanical properties.

[0046] Take the coating, and the components and parts by mass of the coating are as follows:

[0047] Marble 9.5kg, fluorite 4.5kg, rutile 1.5kg, silicon micropowder 1.5kg, metal manganese 1.125kg, ferrosilicon 0.85kg, ferromolybdenum 0.6kg, graphite 0.025kg, metal chromium 0.05kg, iron powder 0.625kg, soda ash 0.1kg , sodium alginate 0.1kg, CMC 0.1kg, boron iron 0.1kg, nickel powder 1.7kg.

[0048] Mix the components of the above-mentioned drug skin evenly, add water glass with a potassium-sodium ratio of 1:1 at 20°C, which accounts for 21.6% of the total mass content of the drug p...

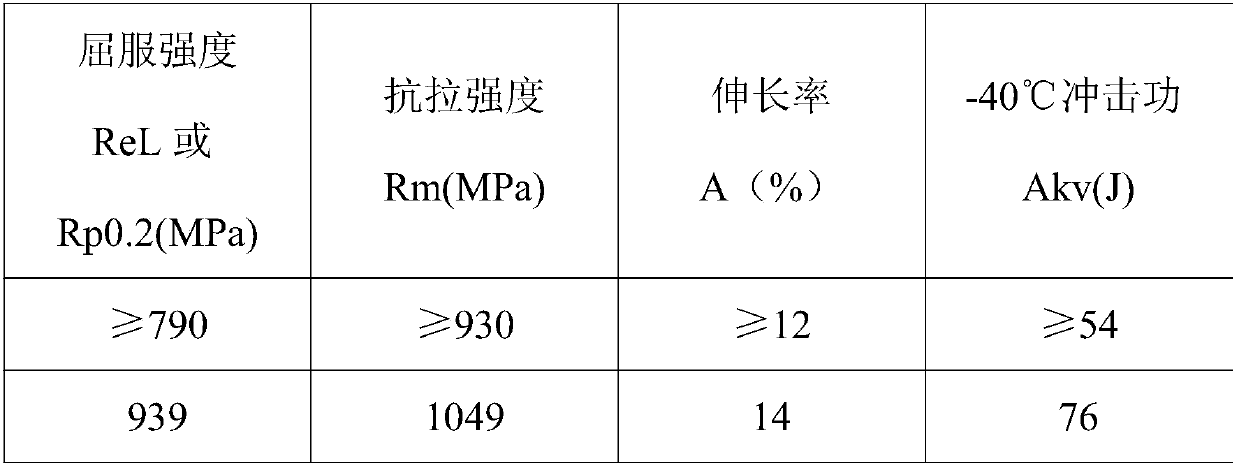

Embodiment 2

[0058] Take the coating, and the components and parts by mass of the coating are as follows:

[0059] 10.5kg of marble, 4.5kg of fluorite, 1.25kg of rutile, 1.0kg of silicon micropowder, 1.05kg of manganese metal, 0.75kg of ferrosilicon, 0.9kg of ferromolybdenum, 0.05kg of graphite, 0.50kg of metal chromium, 0.70kg of iron powder, and 0.1kg of soda ash , sodium alginate 0.2kg, CMC 0.2kg, boron iron 0.05kg, nickel powder 1.75kg.

[0060] Mix the components of the above-mentioned drug skin evenly, add water glass with a potassium-sodium ratio of 1:1 at 20°C, which accounts for 21.6% of the total mass content of the drug powder, and the Baume concentration is 41.3-41.7°Be, and carry out 10-15min. Stir. It is wrapped on the welding core on the hydraulic welding rod production equipment by conventional technology. Then bake at a low temperature of 85°C for 3.5-4 hours, and at a high temperature of 380°C for 1.5 hours, and it is ready.

[0061] The welding rod (DC reverse connect...

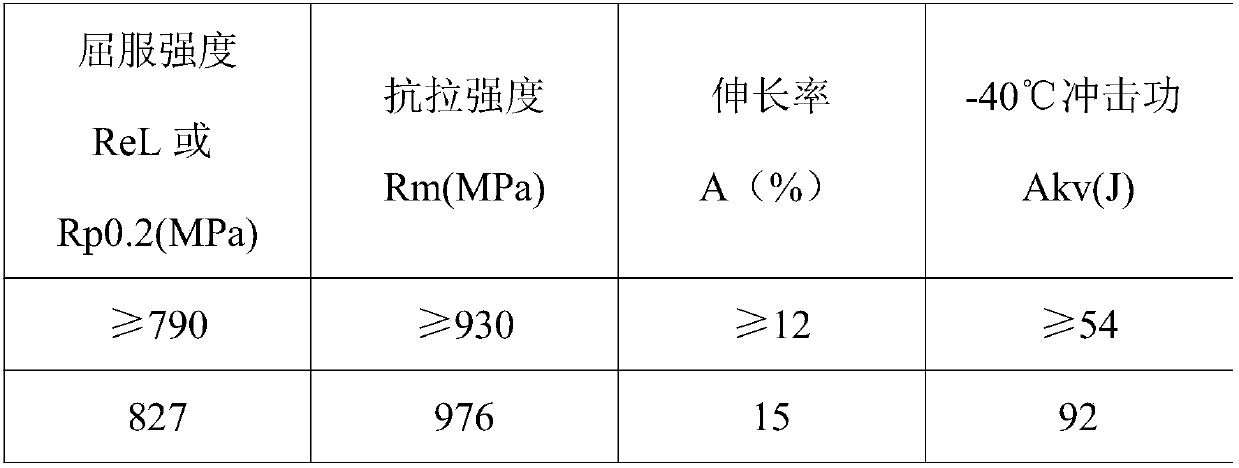

Embodiment 3

[0069] Take the coating, and the components and parts by mass of the coating are as follows:

[0070] 10.5kg of marble, 4.5kg of fluorite, 1.25kg of rutile, 1.0kg of silicon micropowder, 1.05kg of manganese metal, 0.75kg of ferrosilicon, 0.75kg of ferromolybdenum, 0.05kg of graphite, 0.45kg of metal chromium, 0.9kg of iron powder, and 0.1kg of soda ash , sodium alginate 0.2kg, CMC 0.2kg, boron iron 0.05kg, nickel powder 1.80kg.

[0071] Mix the components of the above-mentioned drug skin evenly, add water glass with a potassium-sodium ratio of 1:1 at 20°C, which accounts for 21.6% of the total mass content of the drug powder, and the Baume concentration is 41.3-41.7°Be, and carry out 10-15min. Stir. It is wrapped on the welding core on the hydraulic welding rod production equipment by conventional technology. Then bake at a low temperature of 85°C for 3.5-4 hours, and at a high temperature of 380°C for 1.5 hours, and it is ready.

[0072] The welding rod (DC reverse connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com