WC particle-reinforced Ni-based MIG hardfacing flux-cored wire

A technology of particle reinforcement and welding wire, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve problems such as wear and tear, and achieve the effect of uniform surfacing layer, high welding quality, easy automation and mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

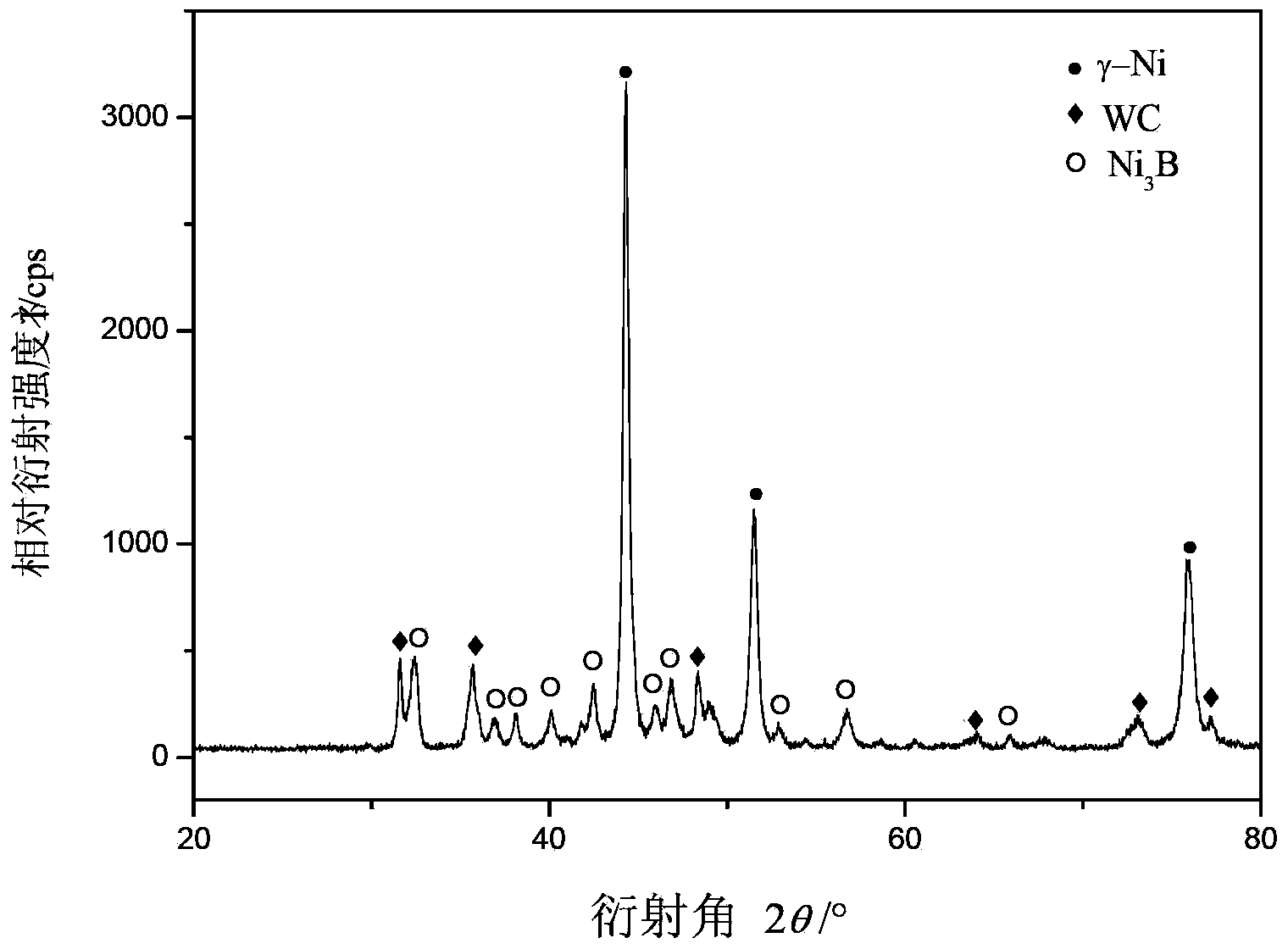

[0035] The nickel-based surfacing flux-cored wire for coal mine picks provided by the present invention, the strip material used in the flux-cored wire sheath is a pure nickel strip with a content of more than 99%, and the filling rate of the flux-cored wire is 30-40%. The core powder includes the following substances in mass percentage: tungsten carbide: 30-75%; silicon carbide: 4-17%; boron carbide: 3-15%; electrolytic manganese powder: 1-5%; sodium fluoride: 1- 12%, the balance is nickel powder. The preparation method of nickel-based surfacing flux-cored welding wire for coal mine picks of the present invention comprises the following steps:

[0036] 1. Roll the Ni strip into a U shape, then add the flux core powder accounting for 30-40% of the flux cored wire gross weight of the present invention in the U shape groove;

[0037] 2. Close the U-shaped groove, wrap the drug core in it, pass through the wire drawing die, draw and reduce the diameter one by one, and finally ma...

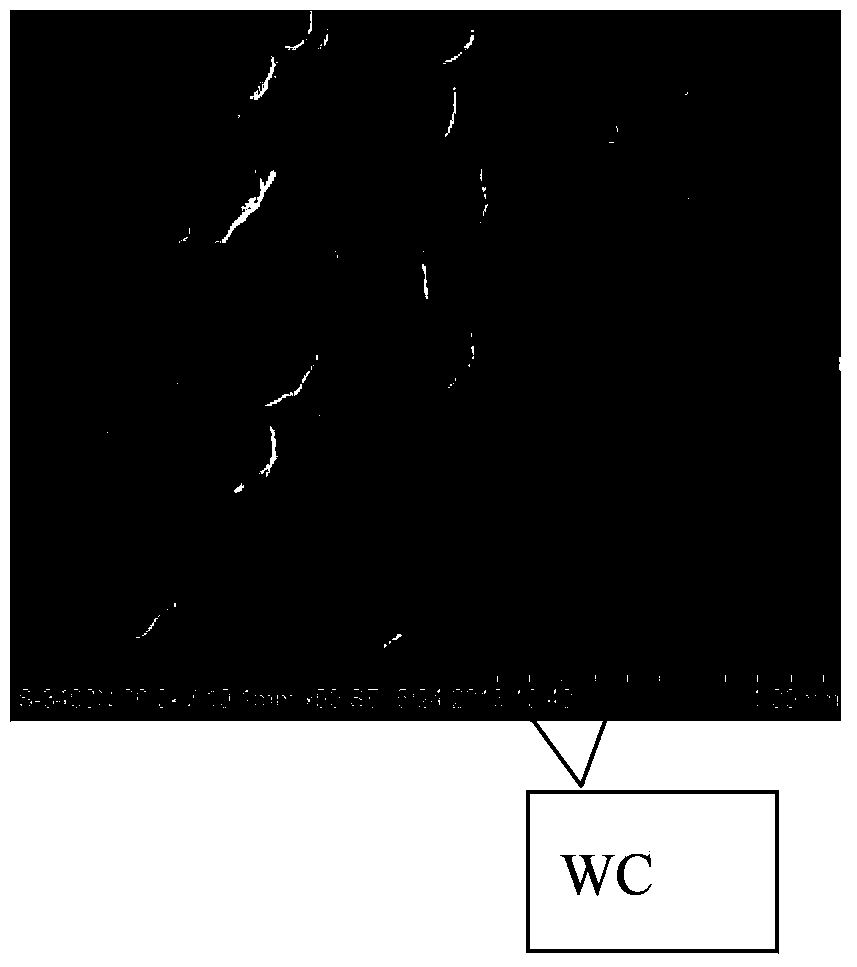

Embodiment 1

[0048] Embodiment 1. A nickel-based wear-resistant surfacing flux-cored wire reinforced with WC particles, including 0.45 kg of cast tungsten carbide, 0.06 kg of silicon carbide, 0.045 kg of boron carbide, 0.010 kg of electrolytic manganese powder, and 0.01 kg of sodium fluoride. Add the obtained flux core powder into the U-shaped nickel tape groove, the filling rate is 37%, and close the U-shaped groove to obtain a WC particle-reinforced wear-resistant surfacing flux-cored wire with a diameter of 1.6mm. The welding process parameters are: 100% argon gas protection, voltage 19V, current 160A. The alloy composition in the obtained deposited metal is: WC: 11.1wt.%; Si: 1.3wt.%; B: 1wt.%; Mn: 0.3wt.%; Ni: balance.

Embodiment 2

[0049] Embodiment 2. A nickel-based wear-resistant surfacing flux-cored wire reinforced with WC particles, including 1.125 kg of cast tungsten carbide, 0.255 kg of silicon carbide, 0.225 kg of boron carbide, 0.075 kg of electrolytic manganese powder, and 0.18 kg of sodium fluoride. Add the obtained flux core powder into the U-shaped nickel tape groove, the filling rate is 40%, and close the U-shaped groove to obtain a WC particle-reinforced wear-resistant surfacing flux-cored wire with a diameter of 1.6mm. The welding process parameters are: 100% argon gas protection, voltage 24V, current 230A. The alloy composition in the obtained deposited metal is: WC: 30wt.%; Si: 5.6wt.%; B: 5wt.%; Mn: 1.48wt.%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com