Sintered flux for stainless steel

A technology of sintering flux and stainless steel, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The composition of flux formulation 1 is shown in Table 1.

[0023] Table 1 Flux Composition of Formulation 1

[0024] edit

No

SiO 2

MnO

MgO

Al 2 O 3

CaF 2

TiO 2

iron

combine

gold

CaCO 3

Na 3 AlF 6

change

thin

soil

match

square 1

3

5

5

35

39

3

2

4

2

2

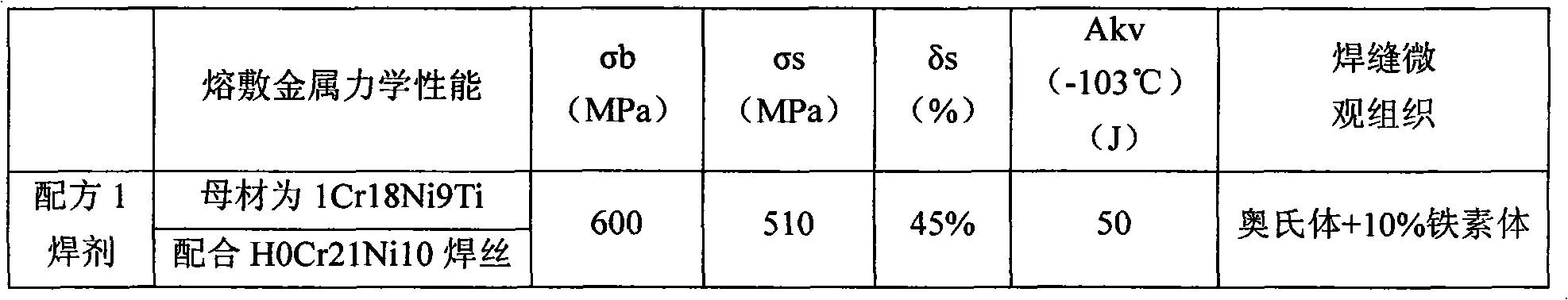

[0025] The mechanical properties of the deposited metal shall be tested in accordance with the provisions of GB17854-1999. The base metal is 1Cr18Ni9Ti stainless steel structural steel, the specification is 650mm×150mm×8mm, the welding wire is H0Cr21Ni10 welding wire, the specification is 3.2mm, the current is 380~400A, the arc vol...

Embodiment 2

[0029] The composition of flux formulation 2 is shown in Table 3.

[0030] Table 3 Flux Composition of Recipe 2

[0031]

edit

No

SiO 2

MnO

MgO

Al 2 O 3

CaF 2

TiO 2

iron

combine

gold

CaCO 3

Na 3 AlF 6

change

thin

soil

match

square 2

5

3

4.5

30

45

2

1.5

2

4

3

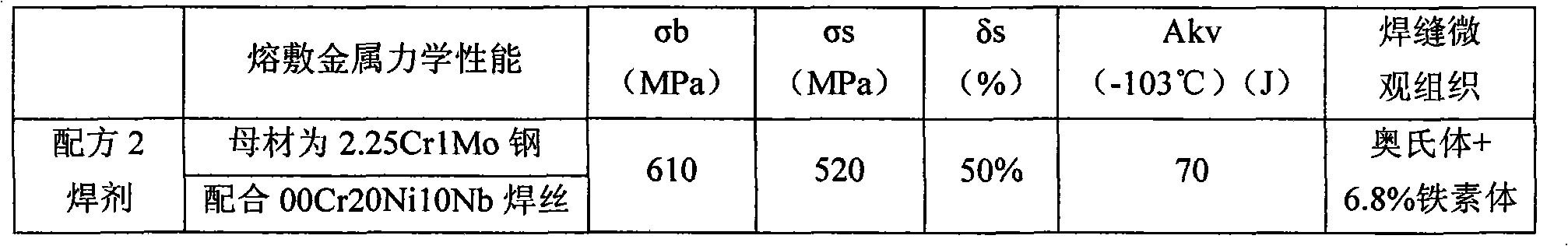

[0032] The hot wall hydrogenation reactor is the core equipment of the petroleum hydrogenation unit. The base material is 2.25Cr1Mo steel, and the inner wall surfacing layer is 00Cr20Ni10Nb stainless steel. The mechanical properties of the material will deteriorate under high temperature and high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com