Special connector crack repair process method

A process method and cracking technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of increased labor intensity, increased brittleness of welds, increased cutting volume, etc., achieving a wide range of applications, low welding costs, and labor. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

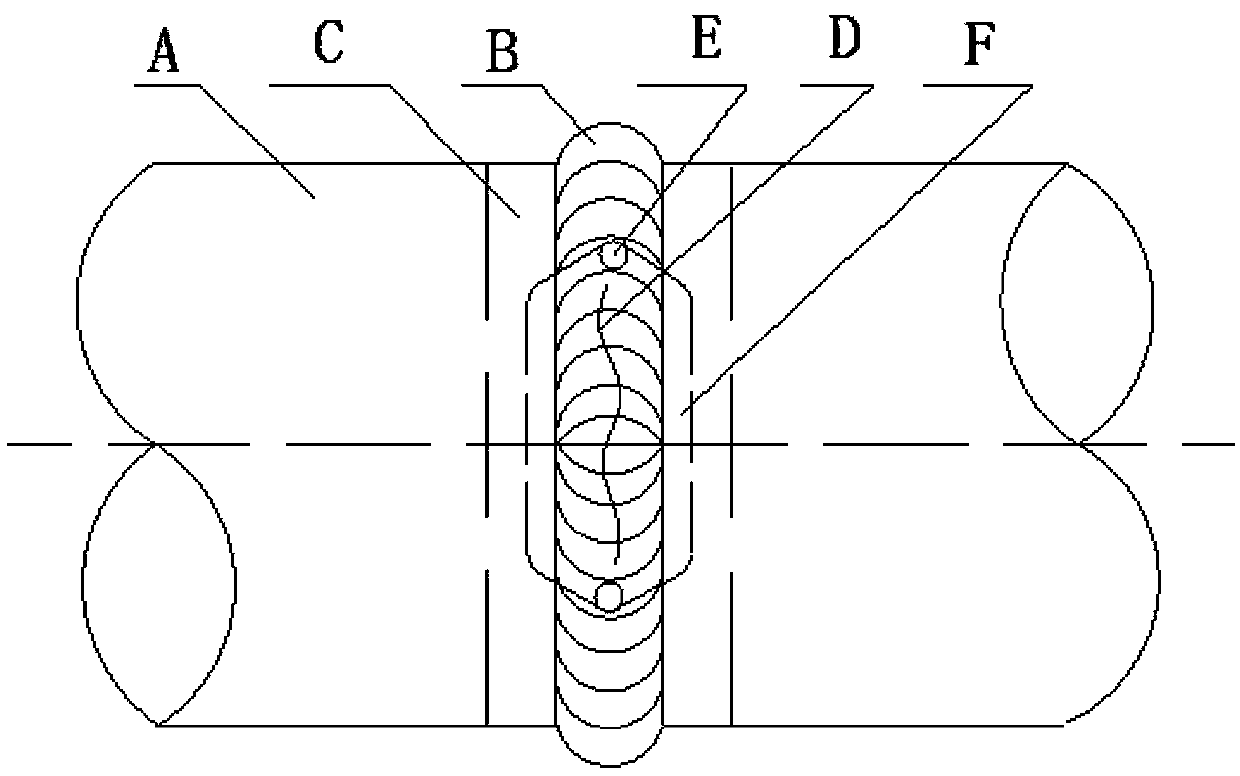

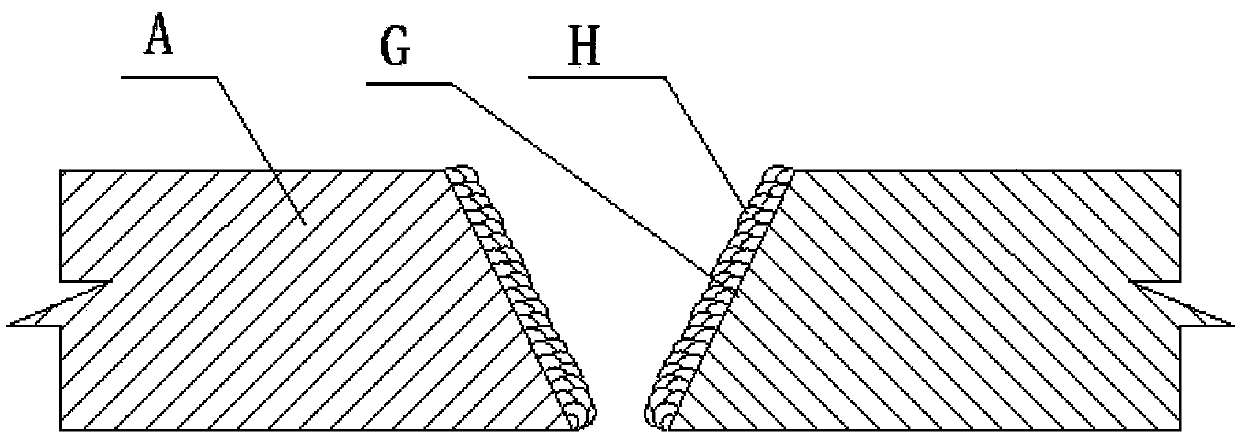

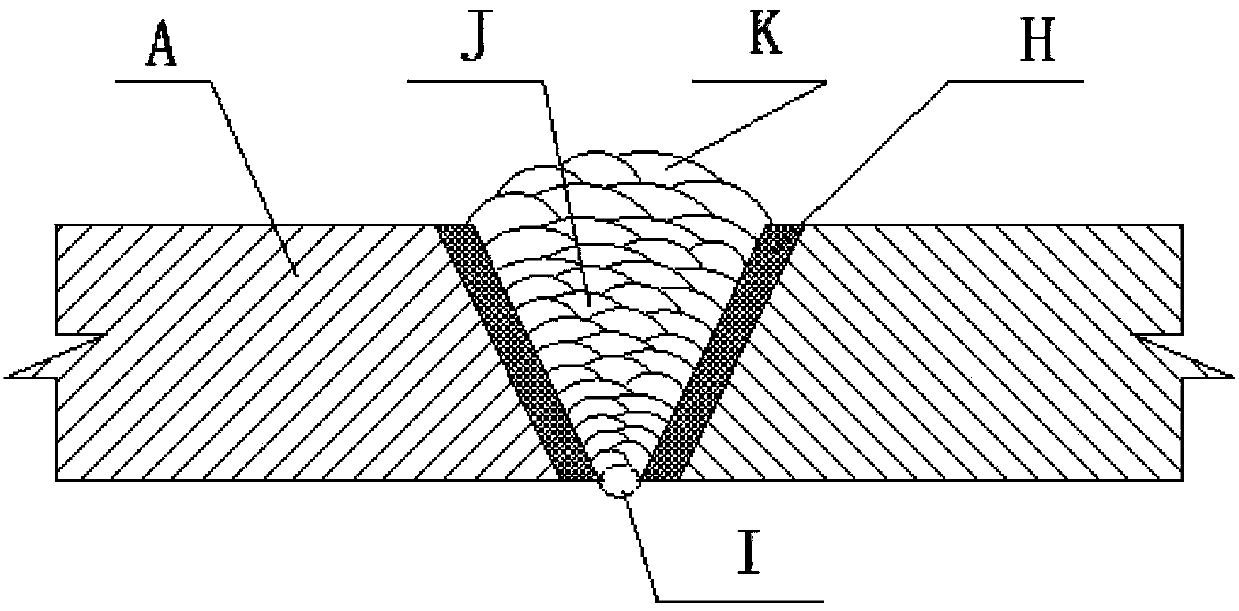

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a special joint crack repair process method includes the following steps,

[0021] Step 1. Carry out ray and coloring inspection on the cracked weld B, and accurately confirm the state of cracks existing inside and outside the weld;

[0022] Step 2. Perform performance restoration on C within 200mm on both sides of the cracked weld (heat treatment area), heat to 670-780°C within 200mm on both sides of the cracked weld, keep it warm for 2 hours and then cool slowly to room temperature for performance restoration. Gradually restore the structure and properties of the base metal after long-term continuous operation at high temperature in a special environment, reduce brittleness, and improve plasticity and toughness;

[0023] Step 3. Drill a Φ6-8mm crack stop hole E at a distance of 20mm from the end point of the crack D. The stress generated during crack cutting can be gradually released through the crack stop ...

Embodiment 2

[0030] Embodiment 2: as figure 1 , figure 2 , image 3 As shown, a special joint crack repair process is suitable for special materials, dissimilar materials, special equipment, and special pipelines that have been continuously operated at high temperature in a special environment for a long time or have multiple temperature fluctuations and changes in tissue composition, resulting in poor weldability and usability. Repair cracks in welded joints. Mainly through ray and coloring inspection; perform performance restoration within 200mm on both sides of the cracked weld; drill a crack stop hole at the end of the crack; completely remove the crack once and for all; ℃; adjust the alloy elements in the weld; change the stress distribution state when the crack is repaired by surfacing; perform post-heat treatment according to the material after welding; carry out multiple operation steps such as ray detection after 48 hours, and perform welding repair to prevent cracks Extension...

Embodiment 3

[0047] Taking the reformer tube of a methanol plant as an example, the material is nickel-based alloy Inconroy 800H, The main component of the conveyed medium is 80% hydrogen, and the normal operating temperature is 830°C. After about 30,000 hours of continuous operation, a crack with a length of 100 mm along the center of the welding seam at the interface between the cold wall pipe and the furnace pipe has occurred. In order to ensure the production, referring to relevant materials and combining practical experience, two methods are used to carry out on-site maintenance.

[0048] Problems existing in the existing special joint crack repair process:

[0049] The cracks are located and cut immediately, after cutting through, the grooves are ground, and the coloring test is carried out. It is found that the cracks still exist, and are more complex than the original cracks, and the length has also increased. Cut again, detect that the crack still exists again, and analyze it: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com