Cu-containing nanophase strengthened easy-to-weld steel and preparation method

An easy-to-weld, nano-phase technology, applied in the field of easy-to-weld steel, can solve the problems of unexplained low-temperature toughness, etc., and achieve the effect of not being prone to cold cracking, good welding performance, and high cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

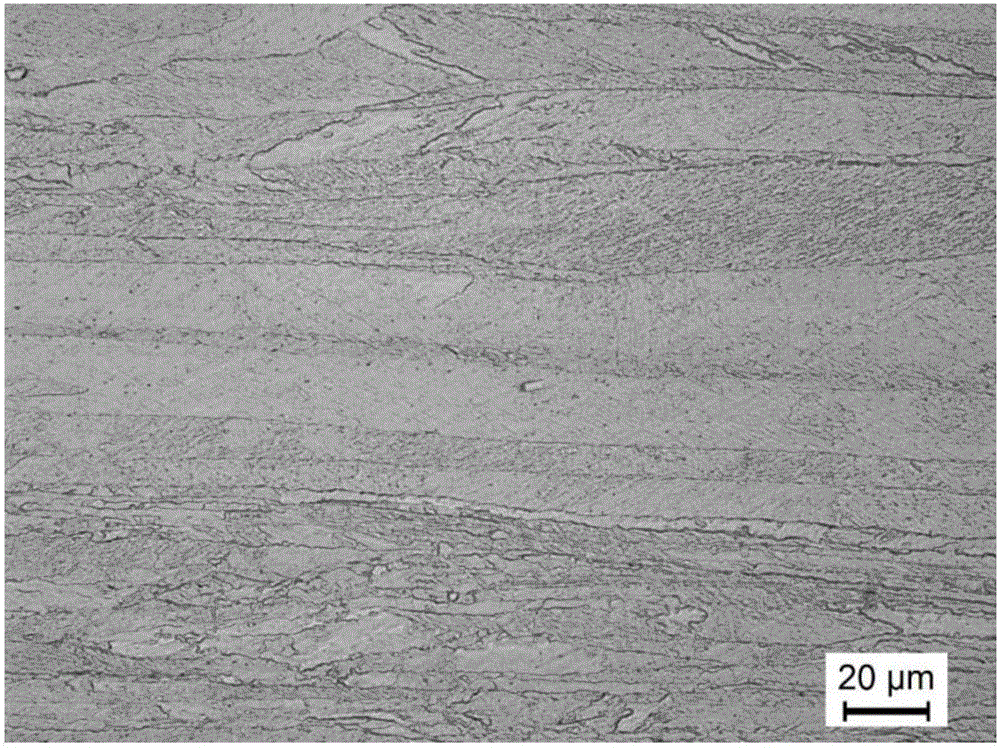

[0033] This embodiment is a high-strength, high-toughness low-alloy steel containing Cu nanophase and its preparation method. The chemical composition (mass percentage) of the alloy is: Cfigure 1 , and its mechanical properties are shown in Table 1

Embodiment 2

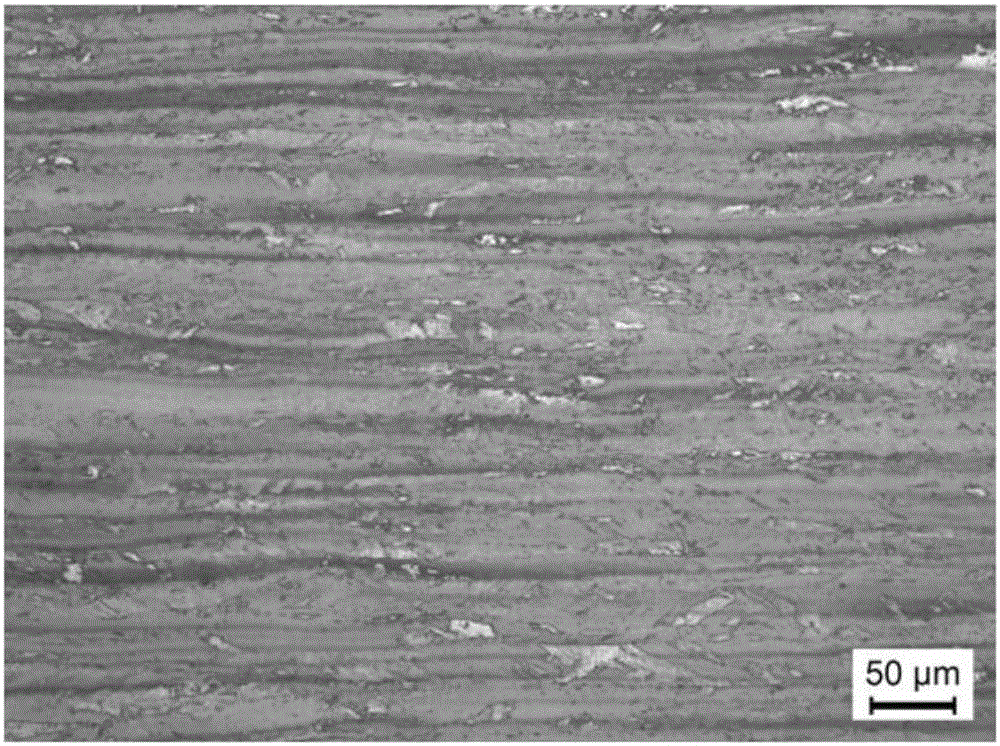

[0035]This embodiment is a high-strength, high-toughness low-alloy steel containing Cu nanophase and its preparation method. The chemical composition (mass percentage) of the alloy is: C figure 2 , and its mechanical properties are shown in Table 1

Embodiment 3

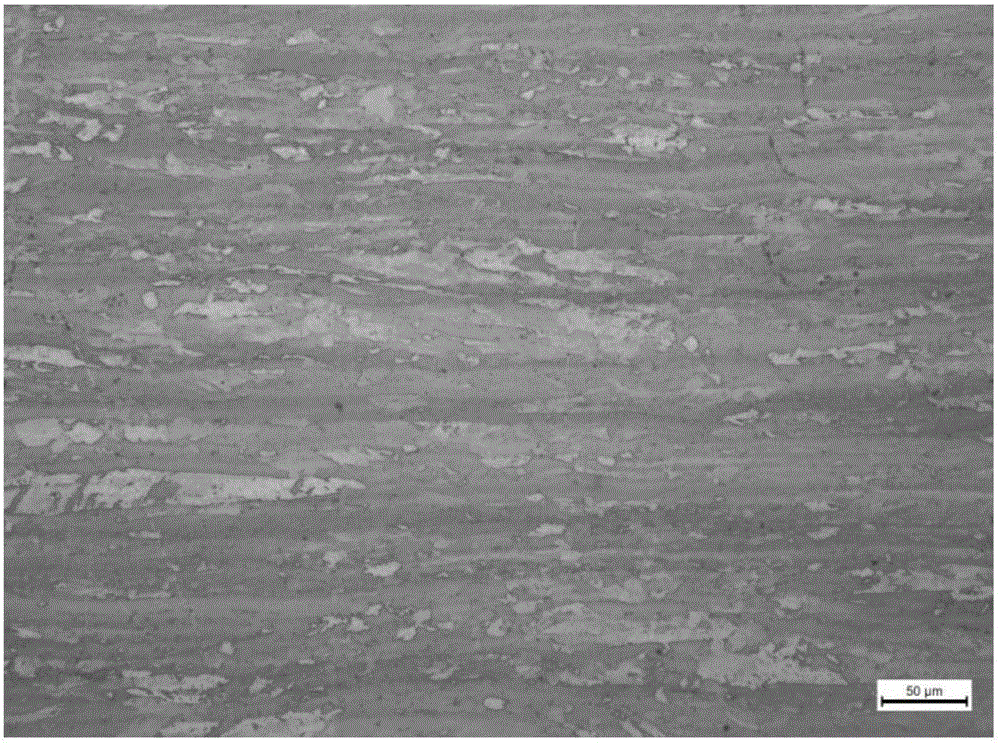

[0037] This embodiment is a high-strength, high-toughness low-alloy steel containing Cu nanophase and its preparation method. The chemical composition (mass percentage) of the alloy is: C image 3 , and its mechanical properties are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com