Resistance welding tube and manufacturing method and application thereof

A resistance welding and copper welding technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of copper tube crystal grain size that cannot meet the requirements, high welding cost, high environmental pressure, etc., to achieve pressure resistance The effect of high strength, reduced welding cost, and reduced welding leak rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

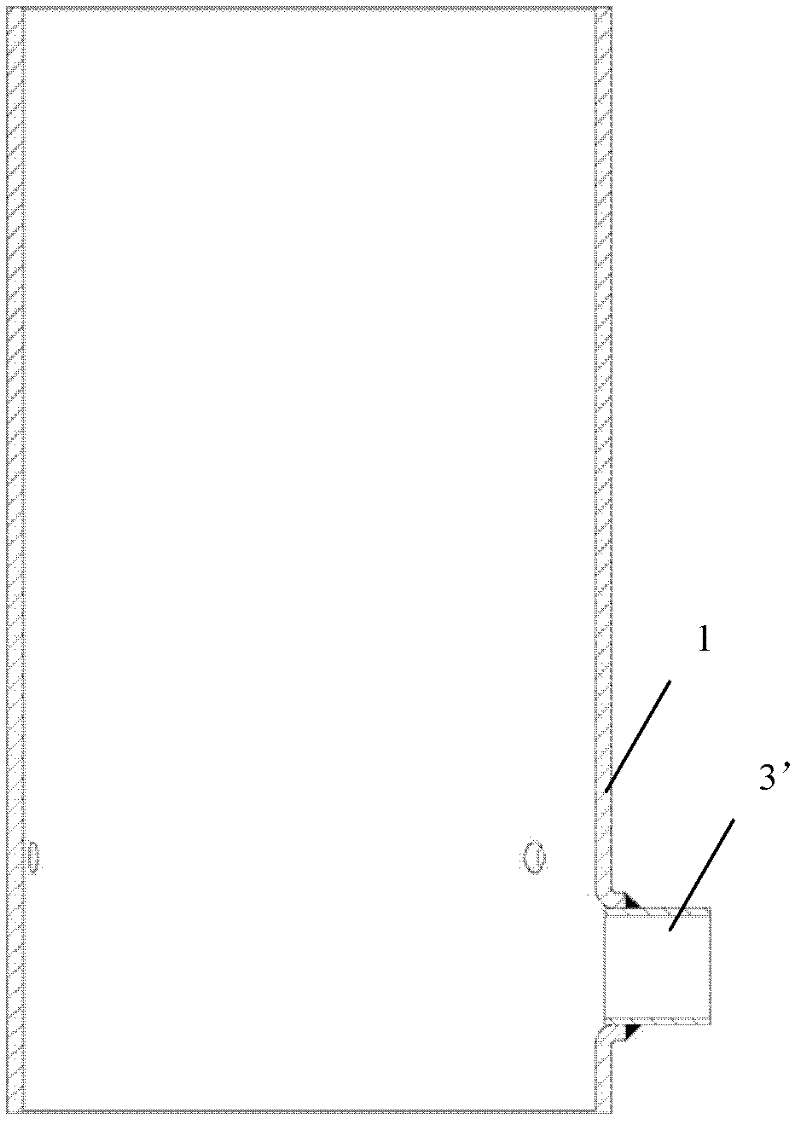

[0027] The preparation method of the above-mentioned resistance welded pipe comprises the following steps: first, as Figure 5 As shown, cut the iron pipe material A to the required size and remove the burrs. Then if Image 6 As shown, copper layer B is plated on the surface of iron pipe A as required, and the electroplating process can be conventional iron copper plating process, which is not limited here. The preferable thickness of the copper layer is 1 μ or more. The iron parts at the two ends of the iron pipe material A can also be covered by the copper layer B. Then, the copper layer at the outer diameter portion of one end of the copper-plated pipe is cut off, so that the iron base material of the iron pipe A is exposed to form an iron welding position 31, and the outer diameter portion of the other end is still covered with a copper layer. The part of B then forms the brazing position 32, such as Figure 7 shown. The copper layer on the inner diameter of the pipe ...

Embodiment

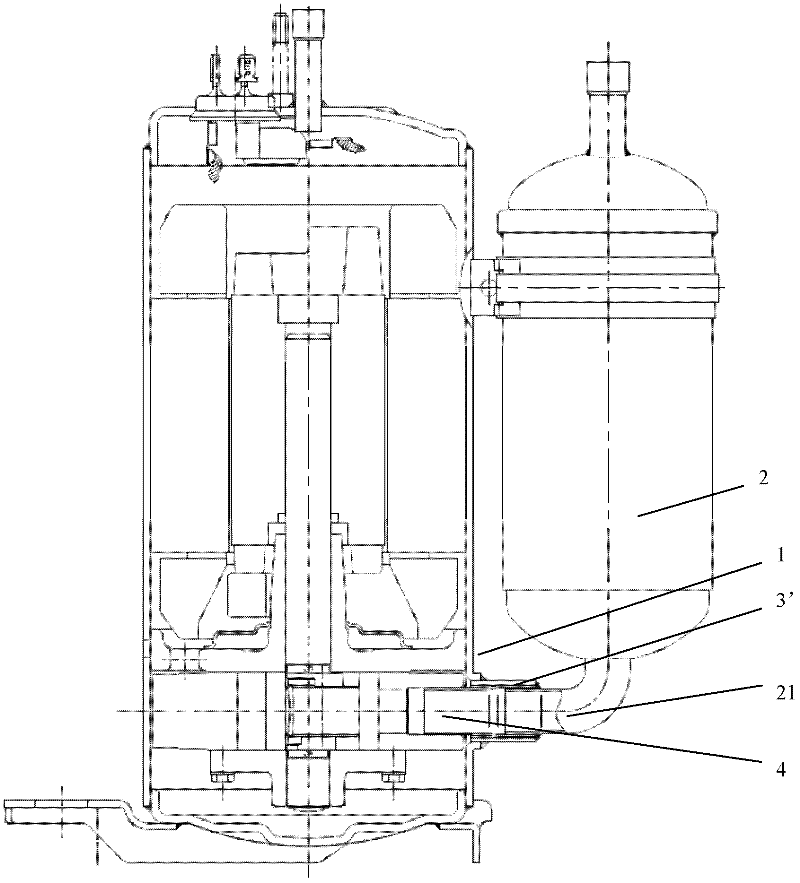

[0032] In the following, the present invention will be further described by taking the application of resistance welded pipes in air conditioner compressors as an example.

[0033] like Figure 7 As shown, the resistance welded pipe in this embodiment is an independent iron pipe A, the outer peripheral surface of one end is covered with a copper layer B to form a brazing position 32, and the other end exposes the iron base material to form an iron welding position 31. At the same time, the position of the iron welding position 31 is turned outward by about 40° to form a flange 33, which is matched with the shell 1 of the compressor. The shell 1 is a cylindrical structure, so the welded pipe should be welded with the cylindrical surface of the shell when the two are assembled. Therefore, preferably, the welded part of the shell 1 is formed by stamping such as Figure 4 As shown in the boss 11, the front section of the boss 11 is an inclined plane with the same valgus angle as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com