Full-automatic detection apparatus suitable for multi-diameter pipe welding seam

A detection device, fully automatic technology, applied in the direction of measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as complex operation process, poor positioning, high labor intensity, etc., and achieve reduction Environmental radiation pollution, good development prospects, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

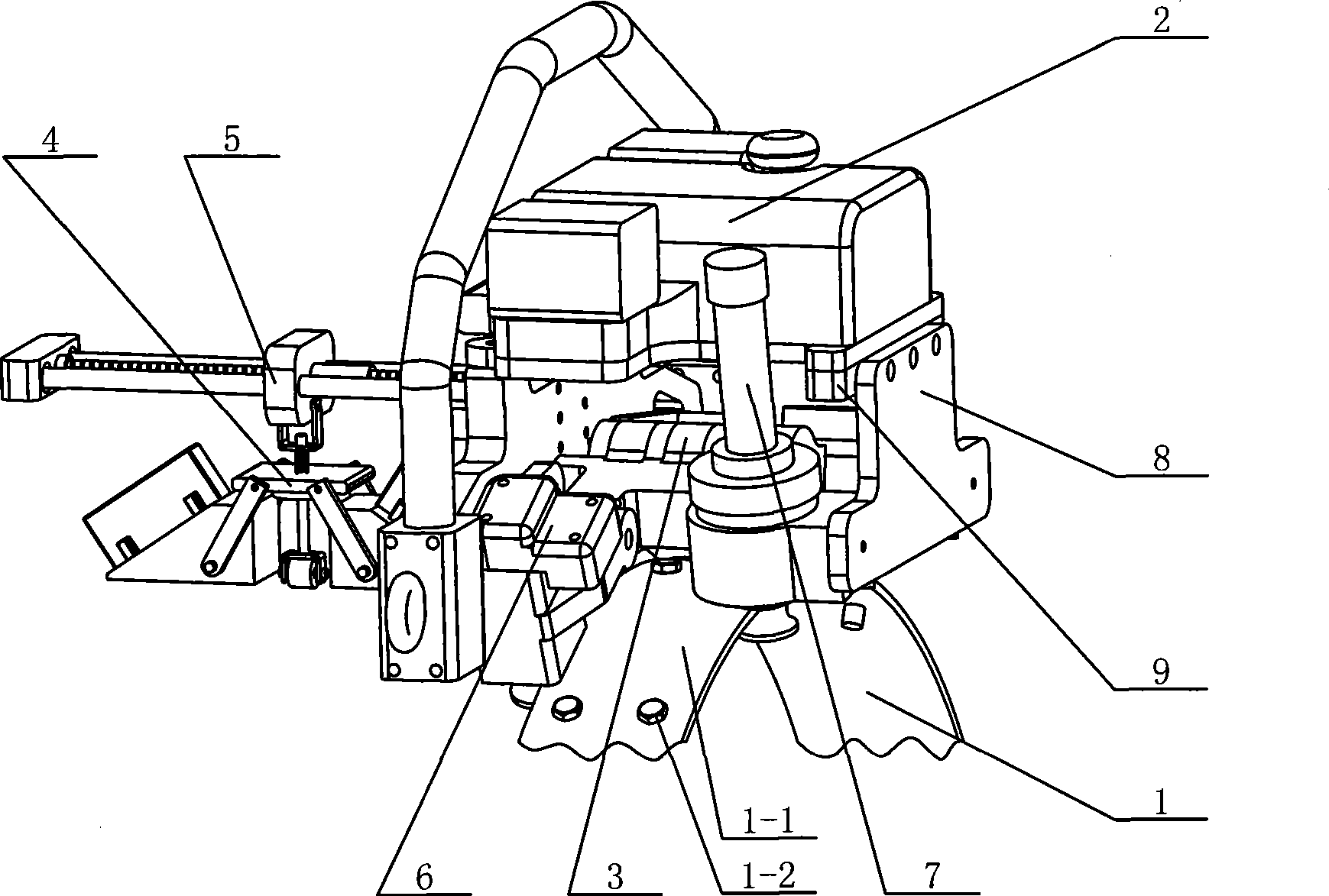

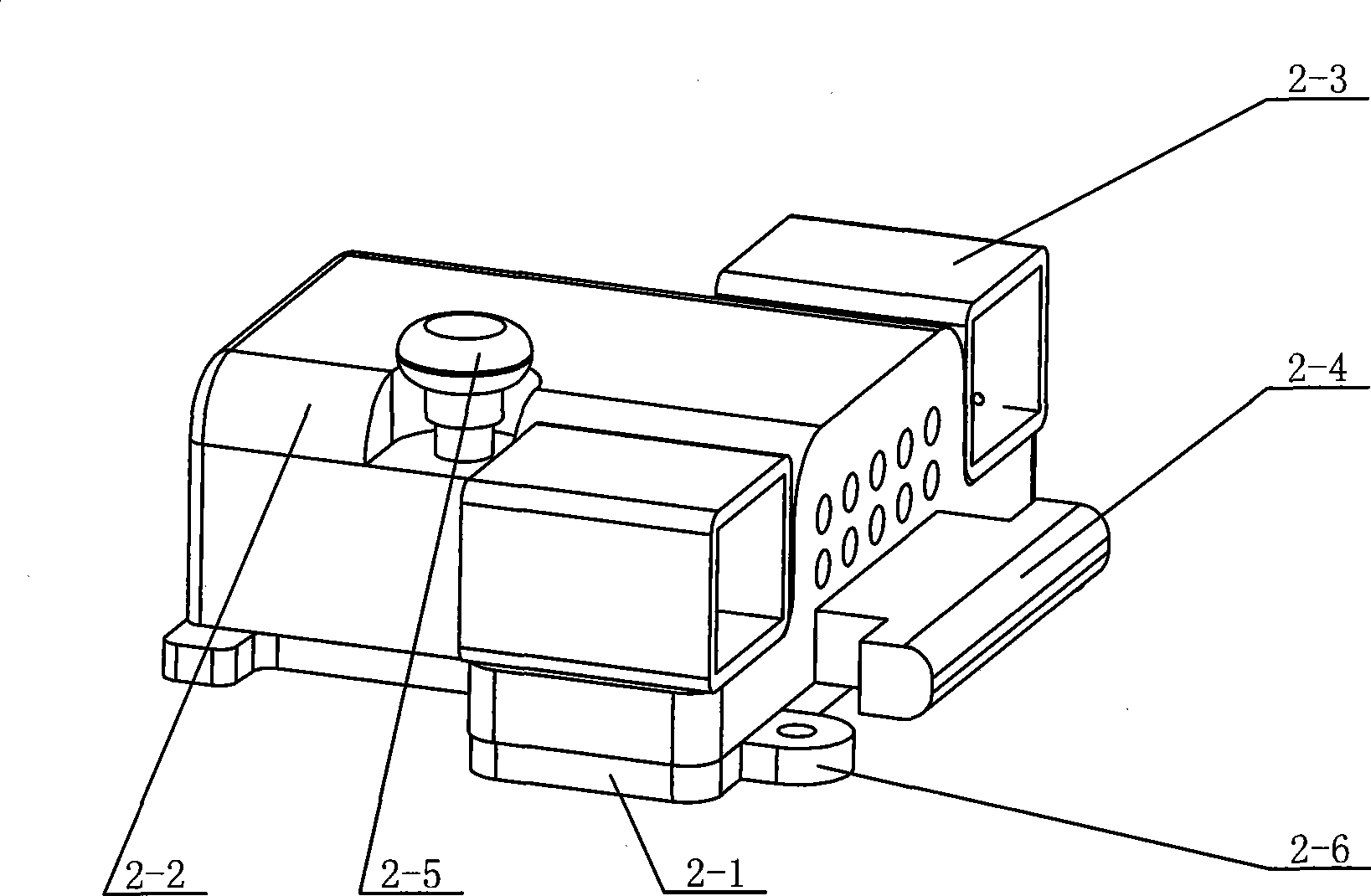

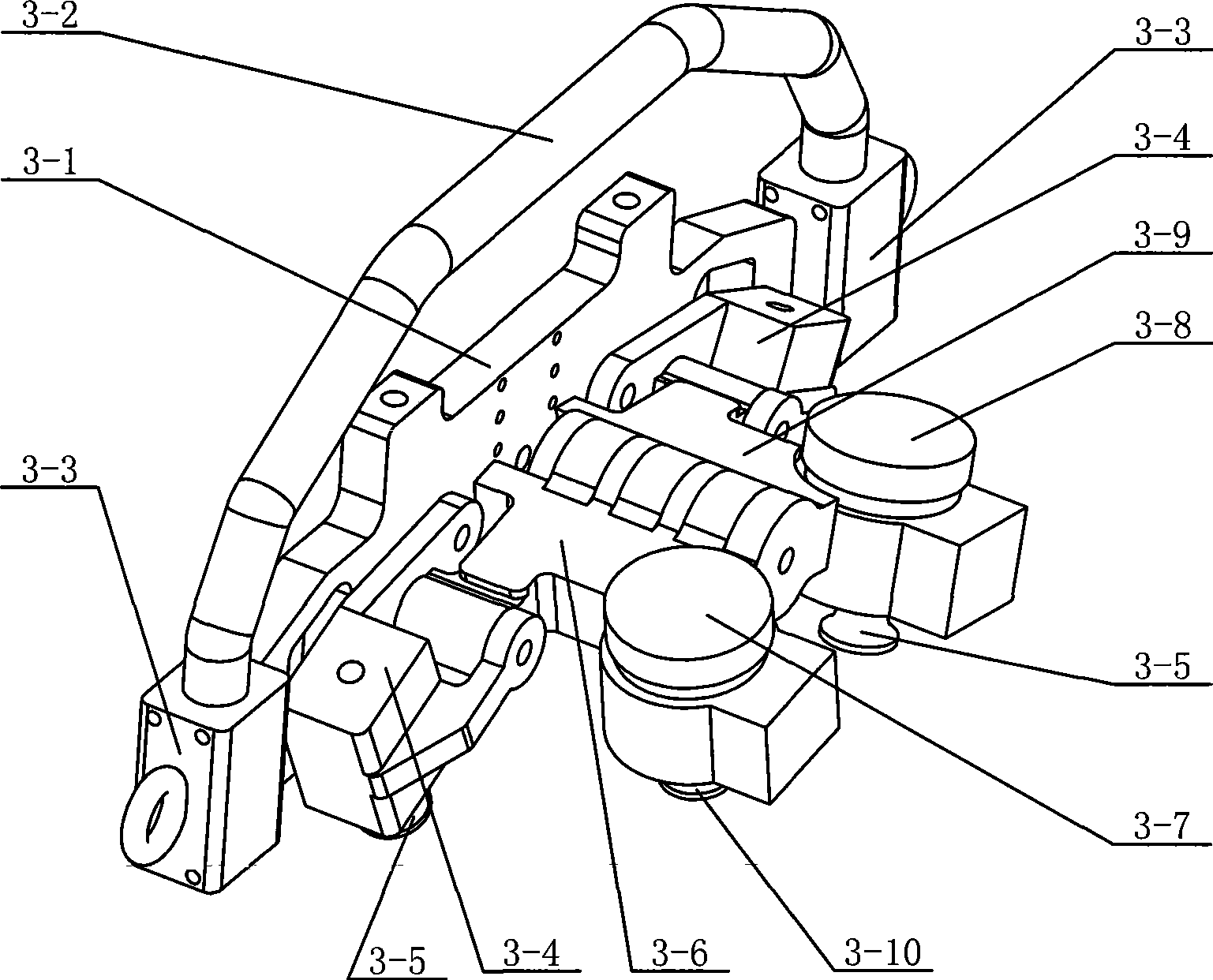

[0021] combine figure 1 , this embodiment is made up of elastic track module 1, scanner module 2, carrier trolley module 3, probe combination module 4, tracking module 5, encoder 6, motor 7, vertical plate 8 and horizontal plate 9; carrier trolley module 3 is installed On the elastic track module 1, the scanner module 2 is fixed on the upper part of the carrier trolley module 3 through the vertical plate 8 and the horizontal plate 9, the probe assembly module 4 is fixed on the side of the carrier trolley module 3 through the tracking module 5, and the encoder 6 is fixed On the angle adjustment block 3-4 of the carrier trolley module 3, the motor 7 is fixedly mounted on the reduction box 3-7 of the carrier trolley module 3. The present invention is externally connected with an ultrasonic flaw detector and an electromechanical control box. Before the flaw detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com