Pipe welding arc-shaped liner device

A technology of arc and liner, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that cannot be adjusted at will, the liner is troublesome to disassemble, and can only be used for large-diameter pipes, etc., to achieve compact structure and easy operation , easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

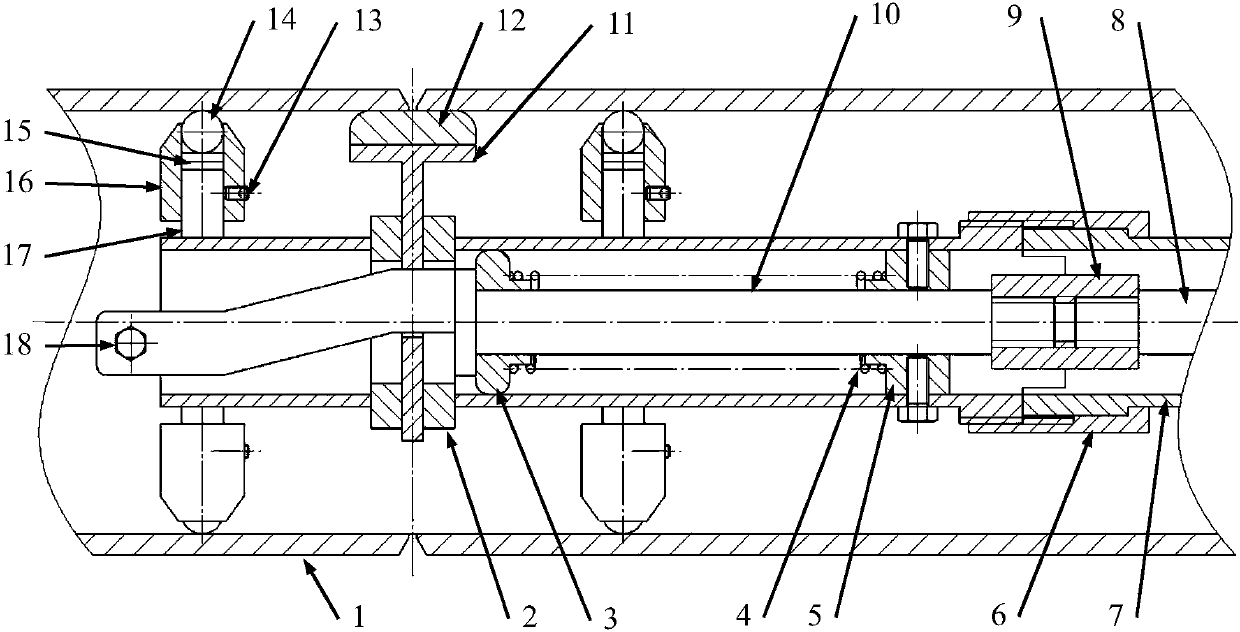

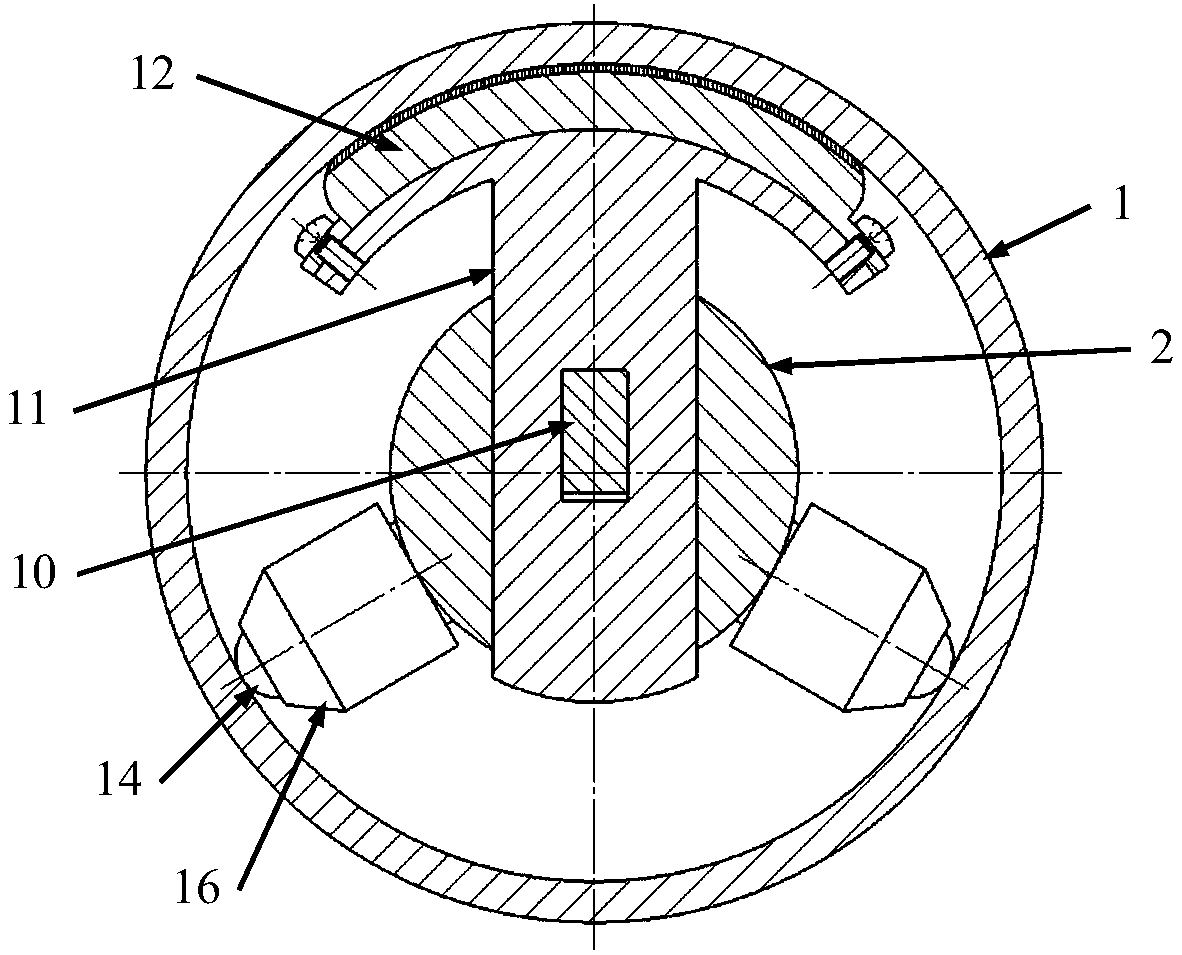

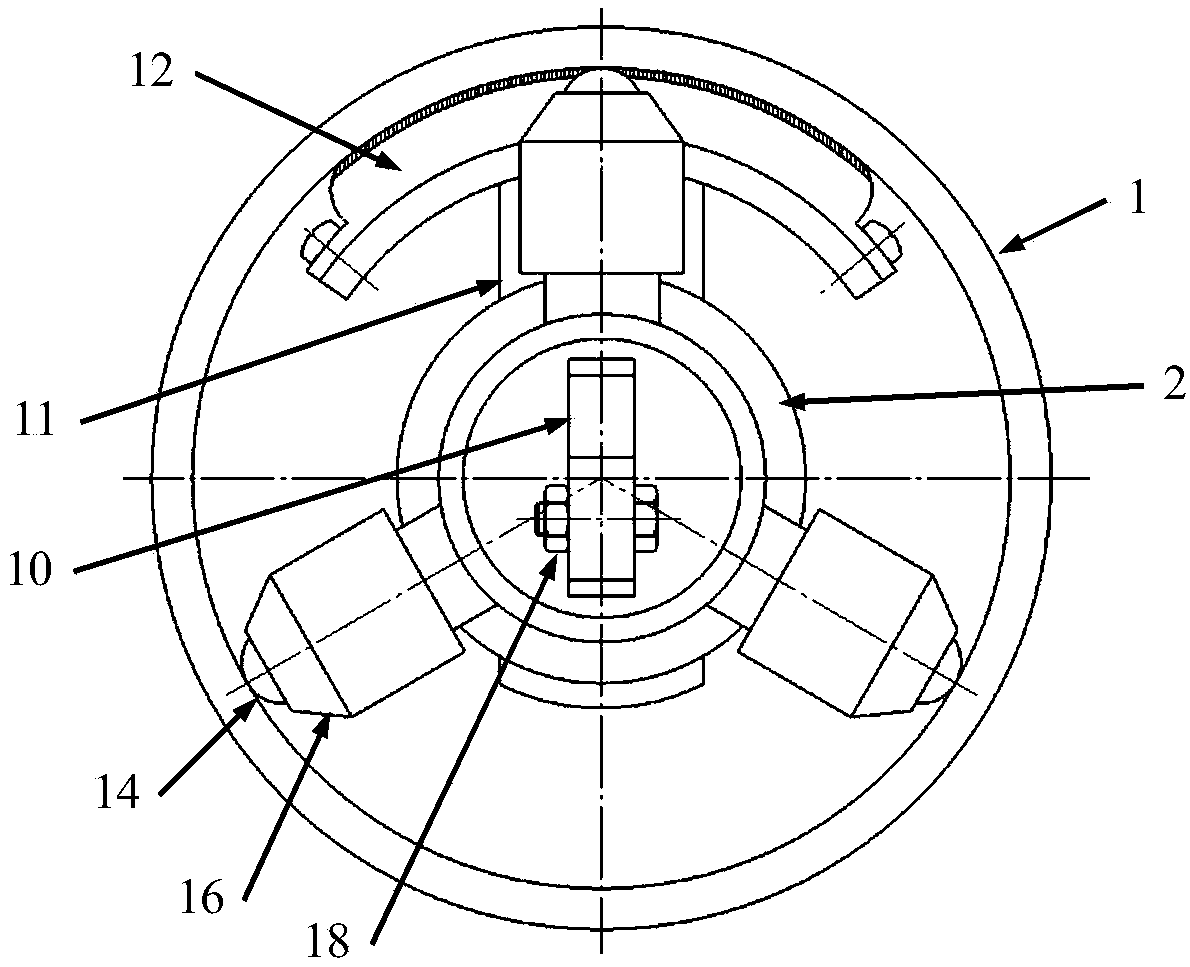

[0040] The present invention will be further described below in conjunction with accompanying drawing:

[0041] Depend on Figure 1 to Figure 20 As shown, the present invention develops an inner liner device used in pipeline welding construction, which is suitable for small and medium-diameter pipelines. The liner is easy to disassemble and can be easily adjusted with changes in the diameter of the pipeline.

[0042] The technical solution adopted by the present invention to solve the technical problem is: the device consists of a head supporting counterpart, a head pad guiding part, an intermediate cylinder rod connecting part, and a tail push-pull positioning part.

[0043] There are 6 groups of said head support counterparts, each group includes 1 fixed top wire, 1 wear-resistant steel ball, several spacer spacers, 1 steel ball cylinder, and 1 steel ball seat. On the left and right sides of the arc-shaped liner of the device, there are 3 sets of head support counterparts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com