Rhombic internal support clamp for round pipe welding

A technology of inner support fixture, rhombus, applied in the direction of household appliances, welding equipment, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

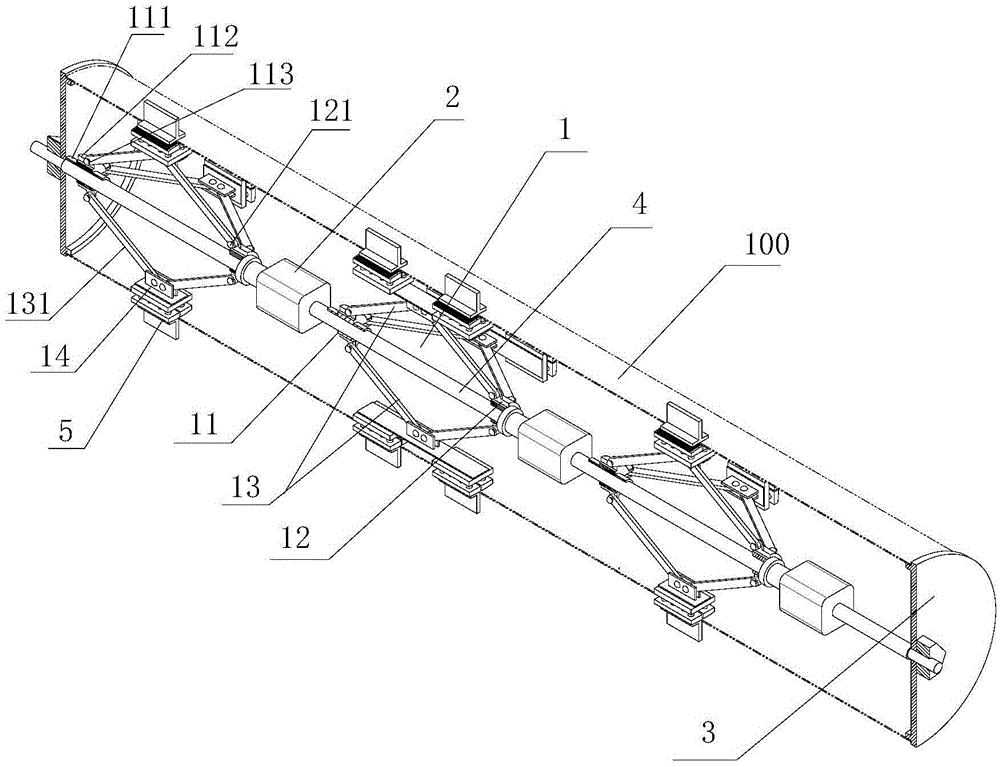

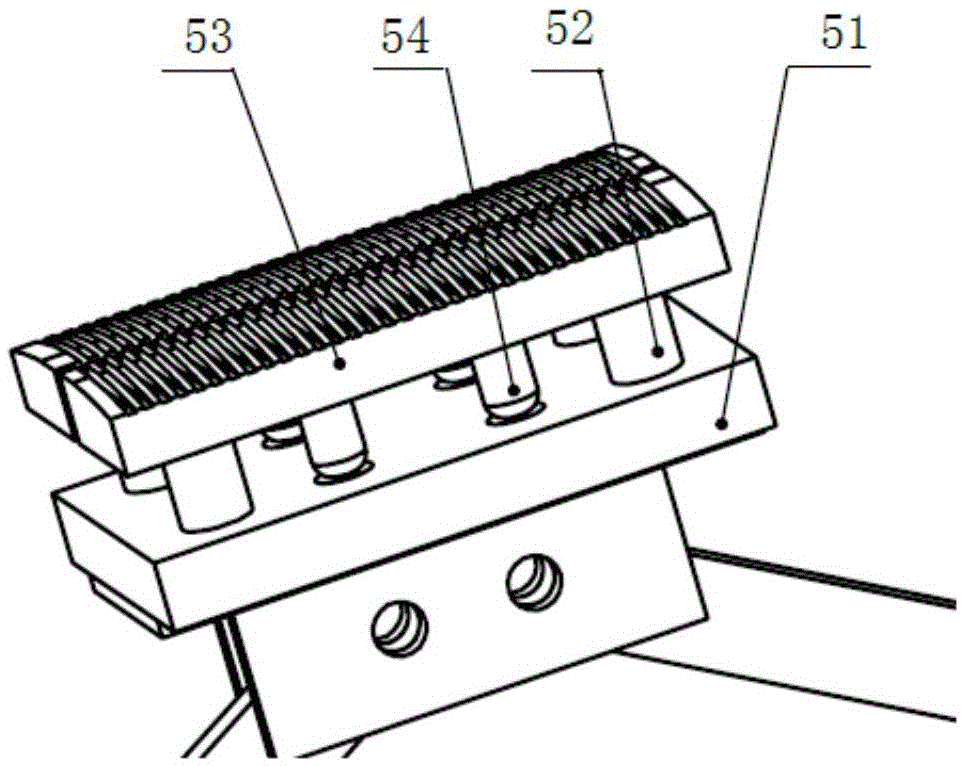

[0037] see figure 1 , the diamond-shaped internal support fixture for round pipe welding of the present invention includes at least one diamond-shaped internal support unit 1, a push cylinder 2 corresponding to the diamond-shaped internal support unit 1, two end caps 3 pressed on both ends of the circular pipe 100, The main shaft 4 and a plurality of braced back blowing modules 5.

[0038] The main shaft 4 is placed at the center of the round tube 100 , and both ends of the main shaft 4 are respectively fixed at the centers of the two end caps 3 .

[0039] Each push cylinder 2 is fixed on the main shaft 4 next to the corresponding diamond-shaped inner support unit 1 .

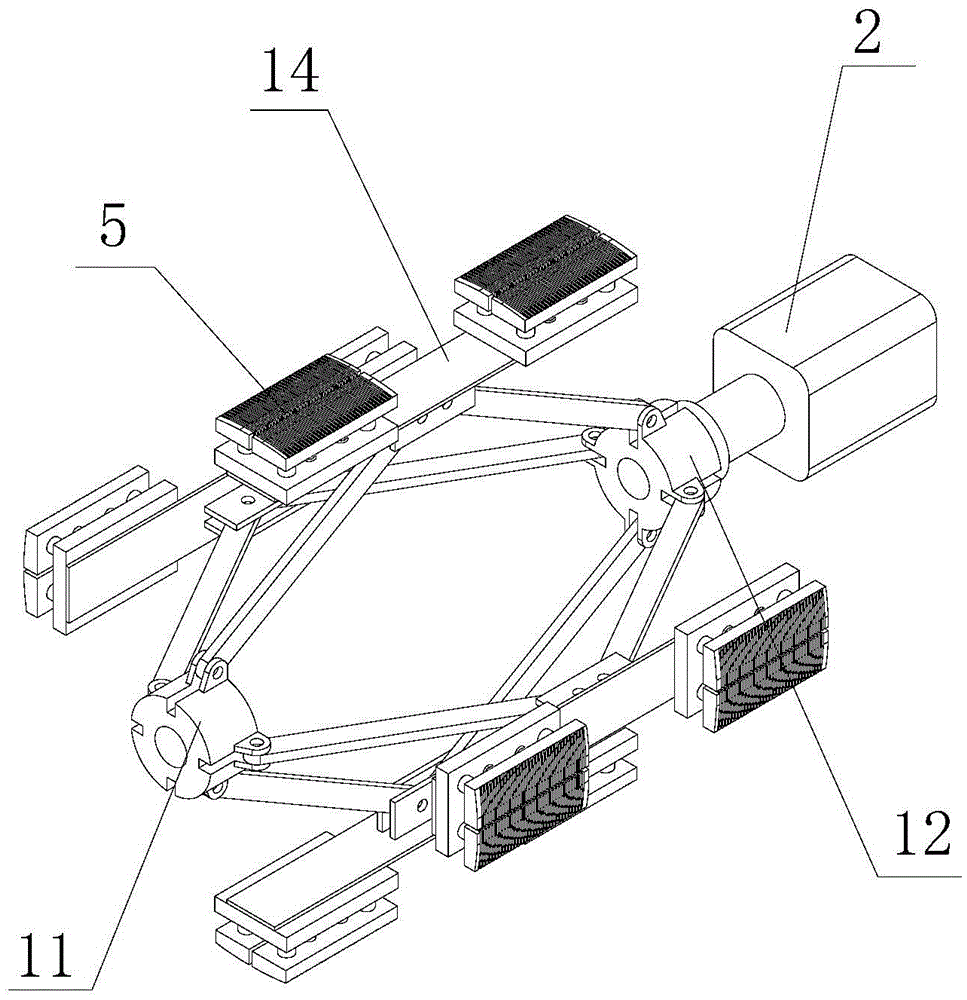

[0040] Each rhombic inner support unit 1 includes a positioning ring 11 , a movable ring 12 , at least one rhombic support frame 13 , and two support platforms 14 corresponding to each rhombic support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com