Welding device for plastic pipe

A technology of welding device and plastic pipe, which is applied in the field of connection and joining of plastic molded parts, can solve the problems such as difficulty in realizing the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

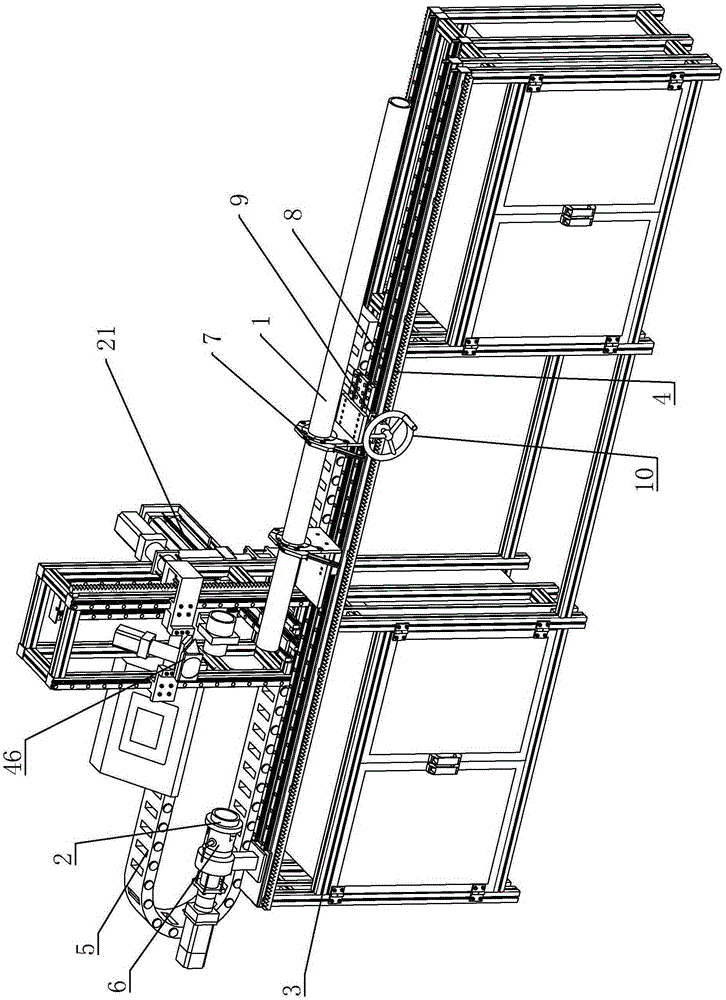

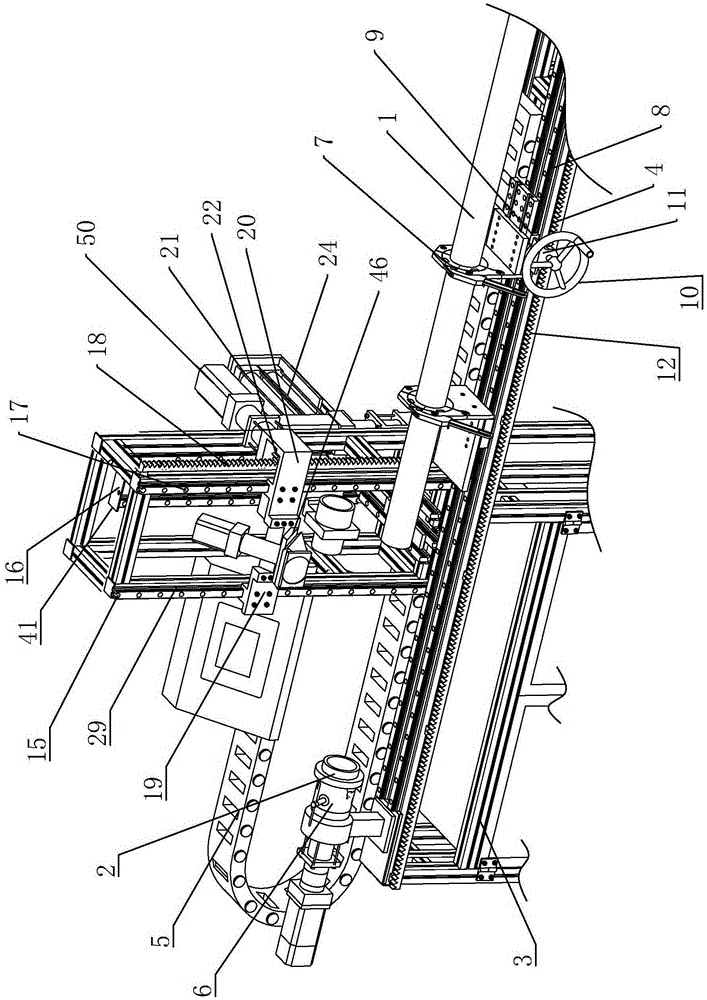

[0042]A plastic pipe welding device, comprising a frame 3, on the frame 3 is provided a pipe clip fixture 7 for clamping the main pipe 1, and a clamp 6 for clamping the pipe welding head 2, the clamp 6 is preferably three claws Chuck, the three-jaw chuck is fixed on the frame 3 through the bracket, and the pipe welding head 2 is fixed on the claws of the fixture 6. There are many kinds of pipe clips on the market, which can only play the role of fixing the main pipe 1. The pipe clip fixture 7 can play a guiding role during work. 6 Relative to the axial linear motion system 4, the linear motion system 4 includes a first guide rail 8 located on the frame 3, a first slider 9 slidably connected to the first guide rail 8, and the first slider 9 is on the first guide rail. There are two distributed on the axis of 8, and the pipe clamping fixture 7 is fixed on the first slider 9. There are also two pipe clamping fixtures 7 to clamp the long cylindrical main pipe 1 to ensure that the ...

Embodiment 2

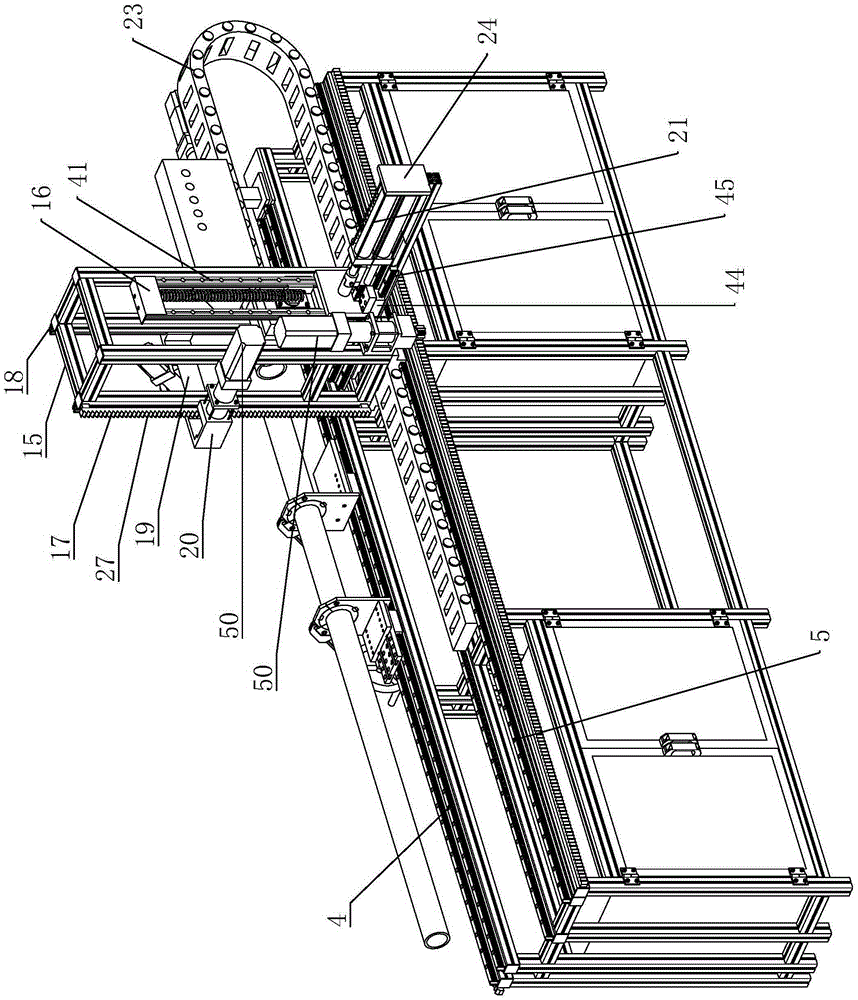

[0063] A plastic pipe welding device, comprising a frame 3, the frame 3 is provided with a pipe clamp fixture 7 for clamping the main pipe 1, a clamp 39 for clamping the branch pipe 40, and a pipe clamp for the main pipe 1 to pass through. The hole provided and the opening communicated with the hole, the axis of the hole is on the same axis as the center clamped by the three-jaw chuck, and the lock piece 14 for rotating and closing the opening is hinged on the pipe clamp fixture 7 body. , to facilitate the installation and disassembly of the supervisor 1.

[0064] The frame 3 is provided with a hot-melt heating device 31 for heating the side wall of the main pipe 1 and the end of the branch pipe 40 respectively. The hot-melt heating device 31 includes a heating assembly 32 and a heater positioned on the heating assembly 32. There is a protruding hot-melt head 34 against the end of the branch pipe 40 and a concave-end hot-melt head 35 against the outer wall of the main pipe 1 ....

Embodiment 3

[0084] A plastic pipe welding device, comprising a frame 3, on which a pipe clip fixture 7 for clamping a main pipe 1, a first clamp 6 for clamping a pipe welding head 2, and a support pipe 40 for clamping are arranged on the frame 3. The second fixture 39 of the second fixture 39, there are many kinds of pipe clips on the market, which can only play the role of fixing the main pipe 1, and the pipe clip fixture 7 can play a guiding role when working. The jig 7 and the first fixture 6 are relative to the axial linear motion system 4. The linear motion system 4 includes a first guide rail 8 located on the frame 3, a first slider 9 slidably connected to the first guide rail 8, and the first There are two sliders 9 distributed on the axis of the first guide rail 8, and the pipe clip fixture 7 is fixed on the first slider 9, and there are also two, and the long cylindrical tube is clamped by the two pipe clip fixtures 7. For the main pipe 1, ensure that the axis of the main pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com