Steel pipe welding data collecting and processing system based on wireless sensor network

A processing system and data acquisition technology, applied in network topology, wireless communication, welding equipment, etc., can solve problems such as quality control difficulties, achieve the effect of eliminating uncertainties and realizing comprehensive quality monitoring and data acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

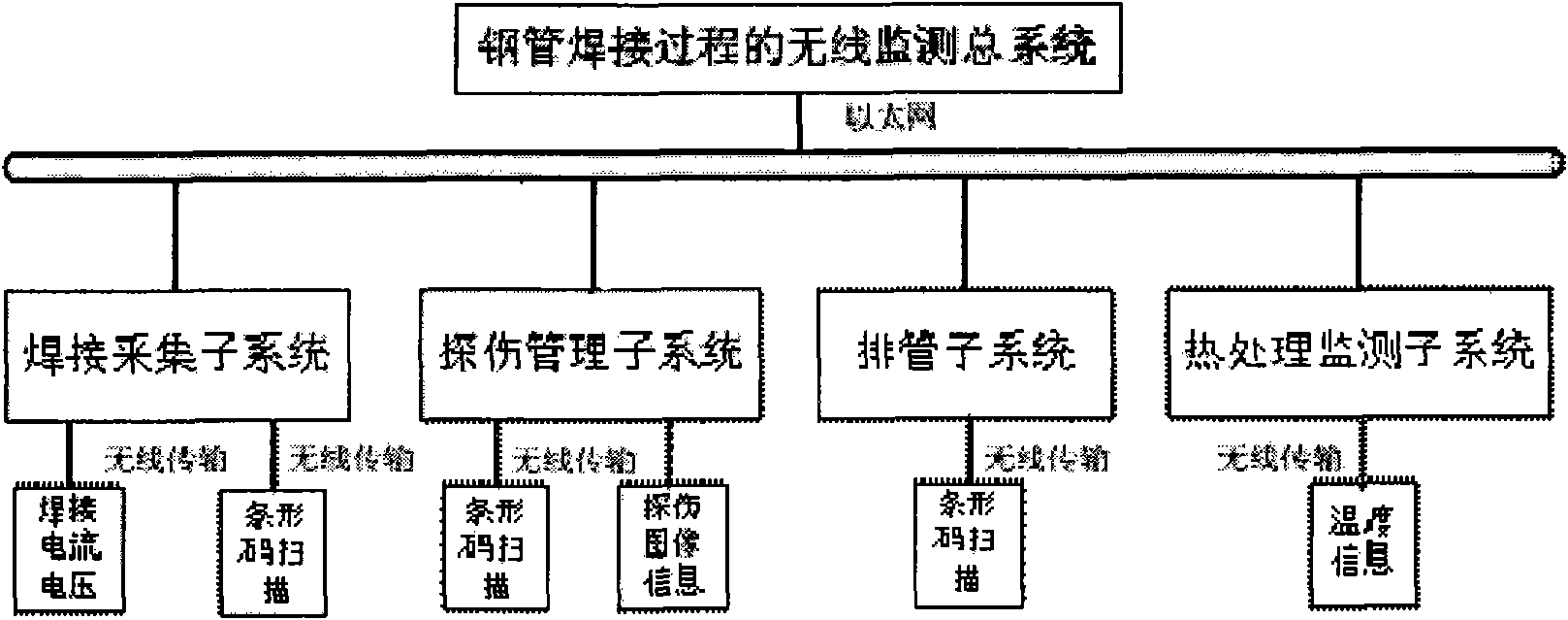

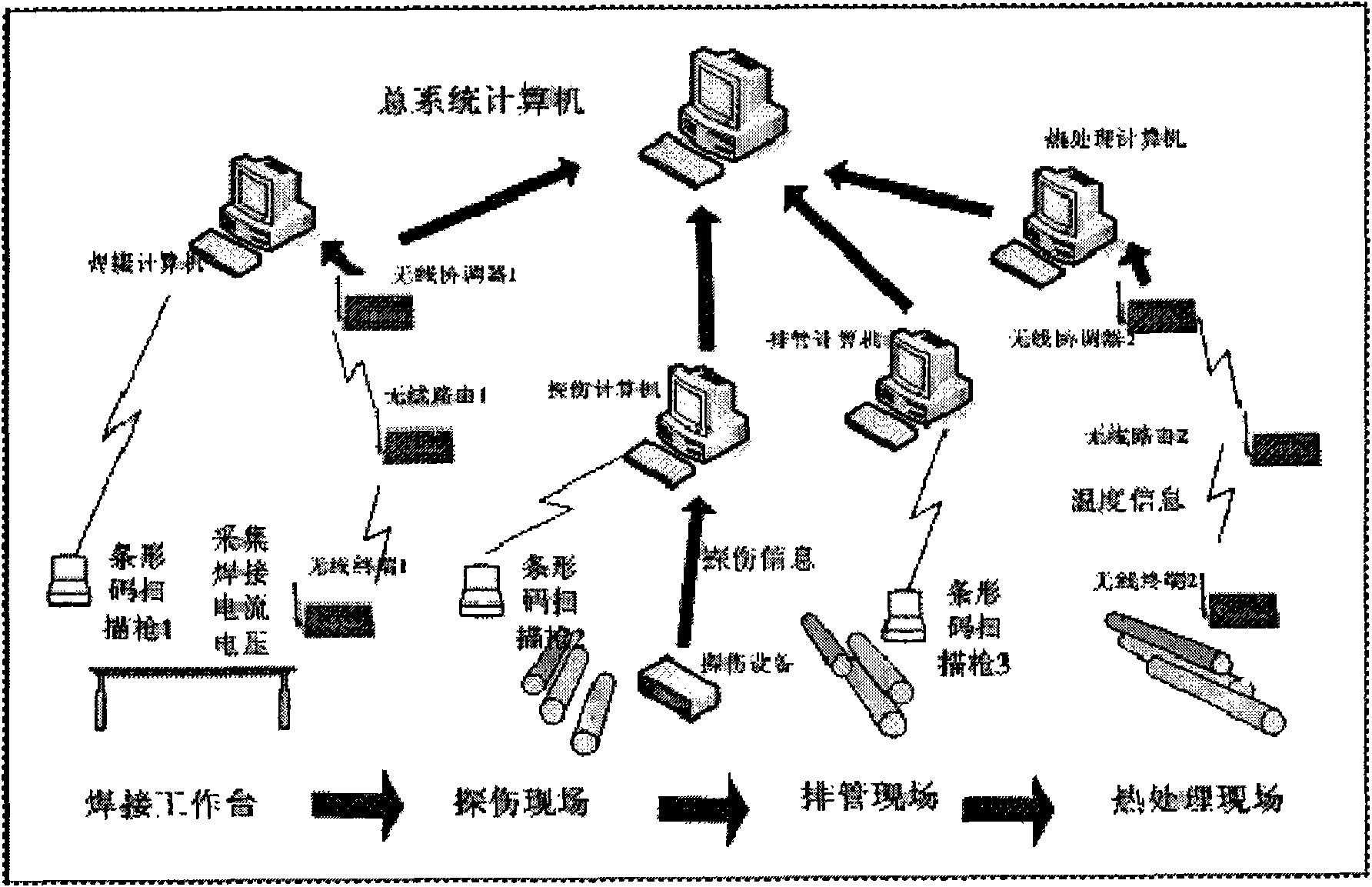

[0013] Such as figure 1 As shown, for the specific steel pipe welding process, using wireless technologies such as IEEE 802.15.4 and RFID, the monitoring system is designed into four corresponding monitoring subsystems: welding information acquisition subsystem, flaw detection management subsystem, pipe arrangement subsystem , heat treatment information acquisition subsystem. The detailed deployment diagram of the whole system is as follows: figure 2 As shown, the function and structure of each subsystem are as follows:

[0014] The welding information acquisition subsystem is designed for the first process of steel pipe processing - welding. Its function is to collect the current and voltage parameters during the steel pipe welding process. The system consists of multiple IEEE 802.15.4 wireless network nodes, welding computer, monitoring instruments and barcode scanning equipment with RFID wireless radio frequency function. The IEEE 802.15.4 wireless network nodes in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com